Sensor unit and instrumented bearing comprising such a sensor unit

一种传感器单元、传感器的技术,应用在转换传感器输出、仪器、测量仪器组件等方向,能够解决导线焊接裸露、焊接损坏夹套等问题,达到防止损坏的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

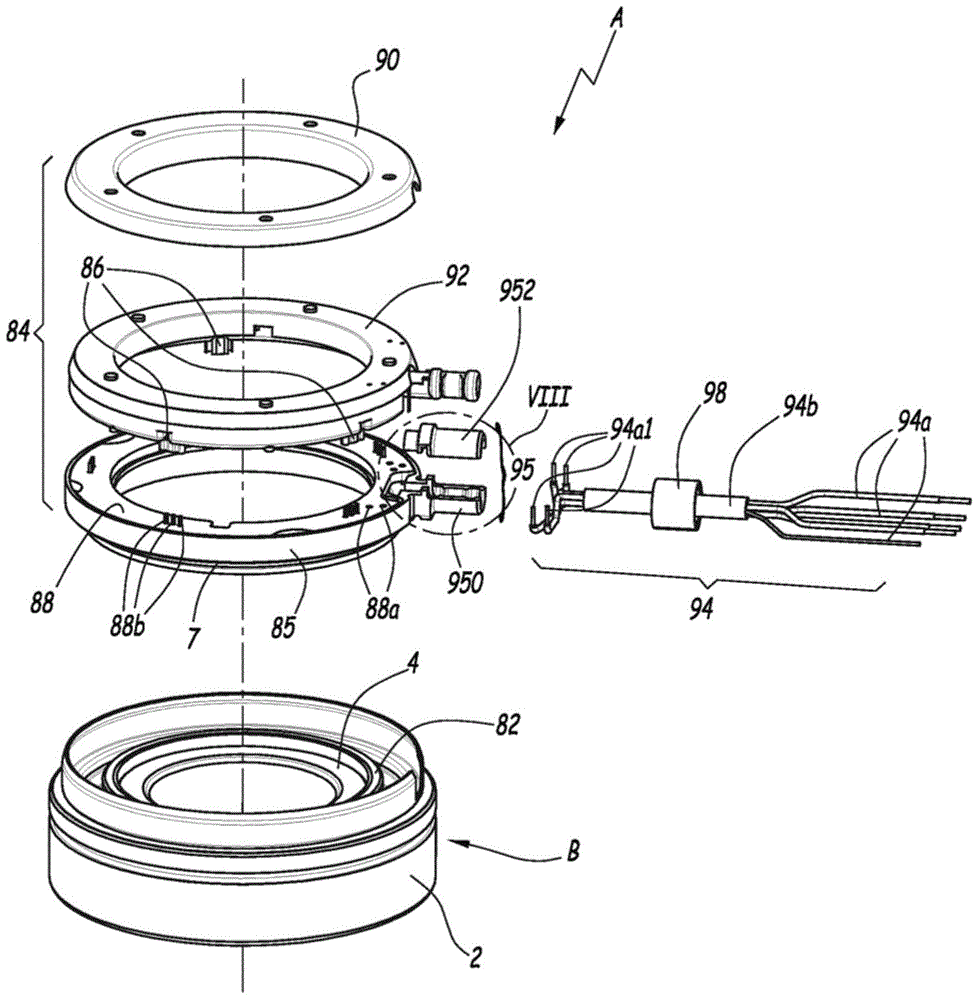

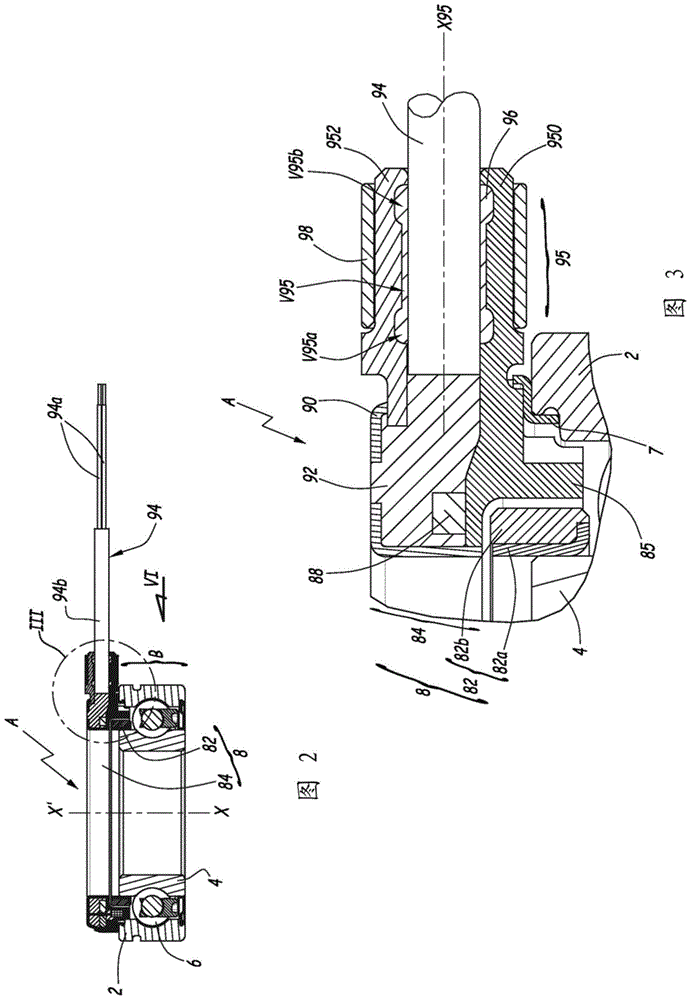

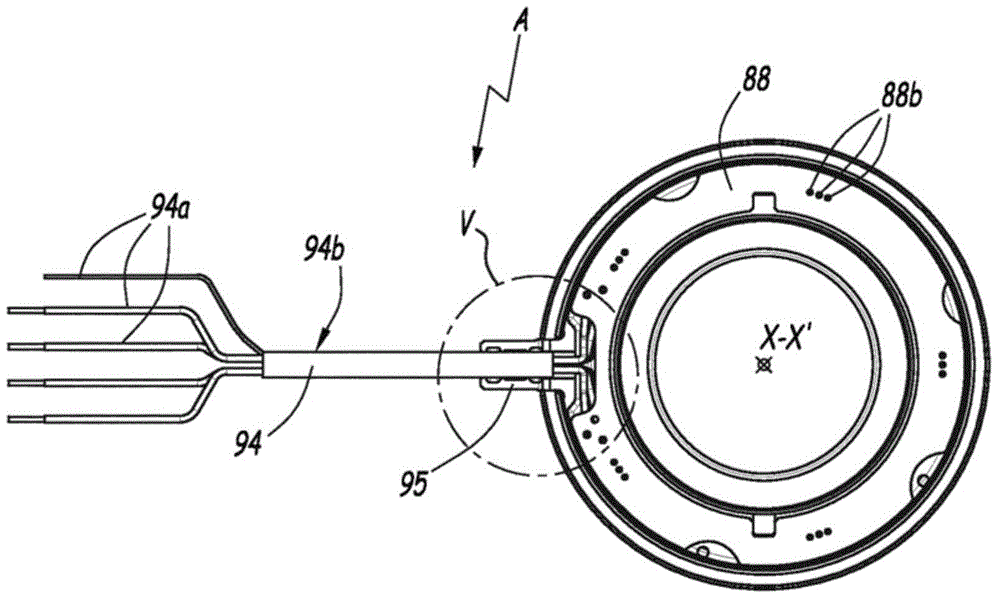

[0032] Figure 1 to Figure 8 Instrumented bearing A is shown on . The instrumented bearing A comprises a bearing B comprising an outer ring 2 forming a non-rotatable element, an inner ring 4 forming a rotatable element, and rolling elements such as balls 6 arranged between the outer ring 2 and the inner ring 4 . The rolling bearing B has an axis of rotation X-X'.

[0033] The instrumented bearing also includes a sensor unit 8 , which includes an encoder 82 , which rotates rapidly with the inner ring 4 . The encoder 82 includes a metal frame 82a and a magnetic ring 82b.

[0034] The sensor unit 8 also comprises a sensor body 84 having an annular shape centered around the axis X-X′ and comprising a plurality of sensing elements 86 fixed relative to the bezel 2 and adapted to be detected by an encoder 82 The rotational speed and direction of the encoder 82 or the angular position is sensed by the change of the magnetic field generated by the rotation about the axis X-X'. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com