a brush strip

A brush strip and brush technology, applied in the field of brush strips, can solve problems such as unfavorable vacuum degree of vacuum cleaners and difficult cleaning, and achieve the effect of improving vacuum degree and increasing support force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

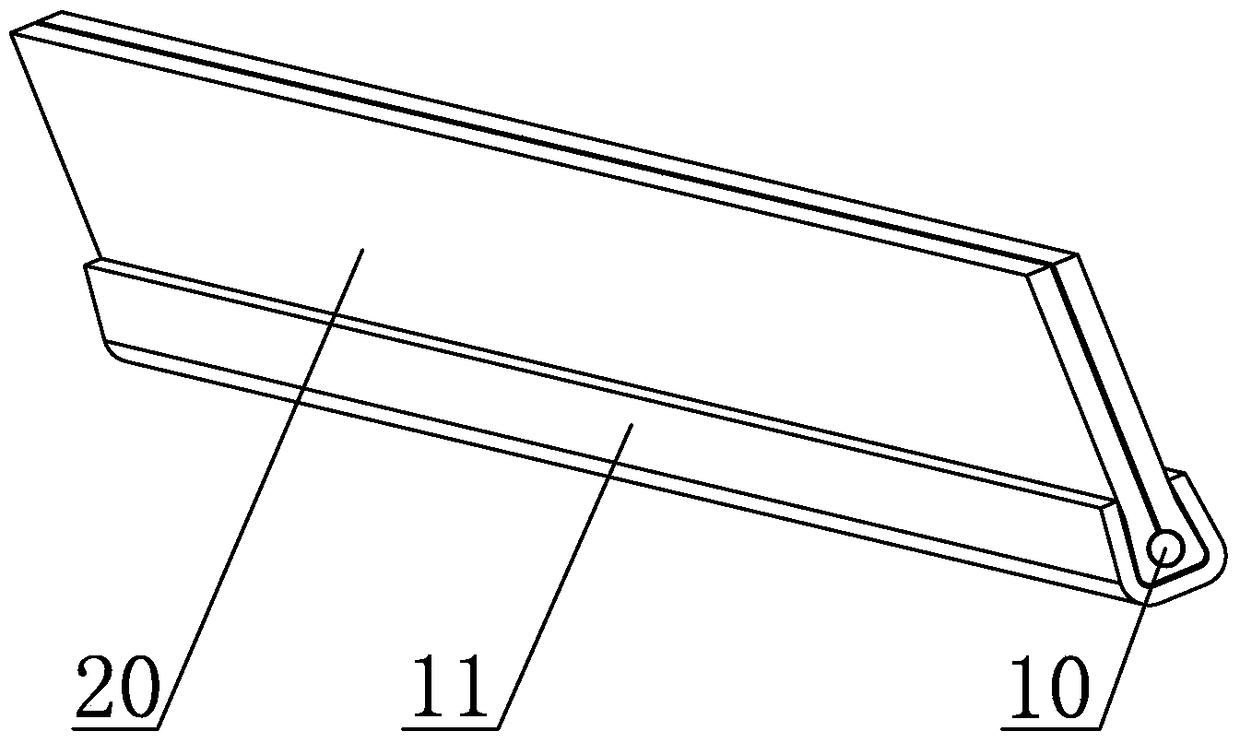

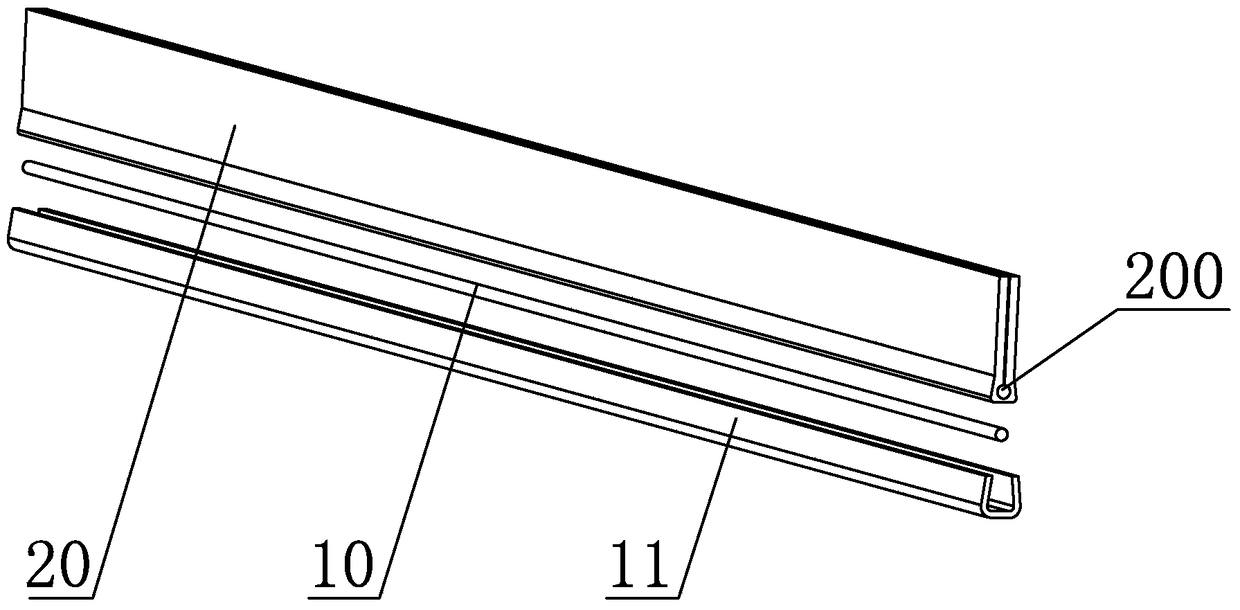

[0026] like image 3 , 4 A brush strip shown includes a fixing part 1 and a bristle part 2 . Specifically:

[0027] The fixing part 1 includes a fixing rod and a covering part, wherein: the fixing rod is an iron wire 10; the covering part is an iron sheet 11 with a U-shaped cross section.

[0028] The bristle portion 2 includes a plurality of bristle filaments 20 and a soft sheet 21, the soft sheet 21 adopts PE (polyethylene), the plurality of bristle filaments 20 are distributed along the width direction of the brush, and one end of the plurality of bristle filaments 20 and the soft sheet 21 is It is fixed by the fixing part 1, and the width of the soft sheet 21 is consistent with the distribution width of the plurality of bristle filaments 20, and the other end of the soft sheet 21 is flush with the other end of the plurality of bristle filaments 20.

[0029] In this embodiment: a plurality of bristle filaments 20 are located between two soft sheets 21 . The specific str...

Embodiment 2

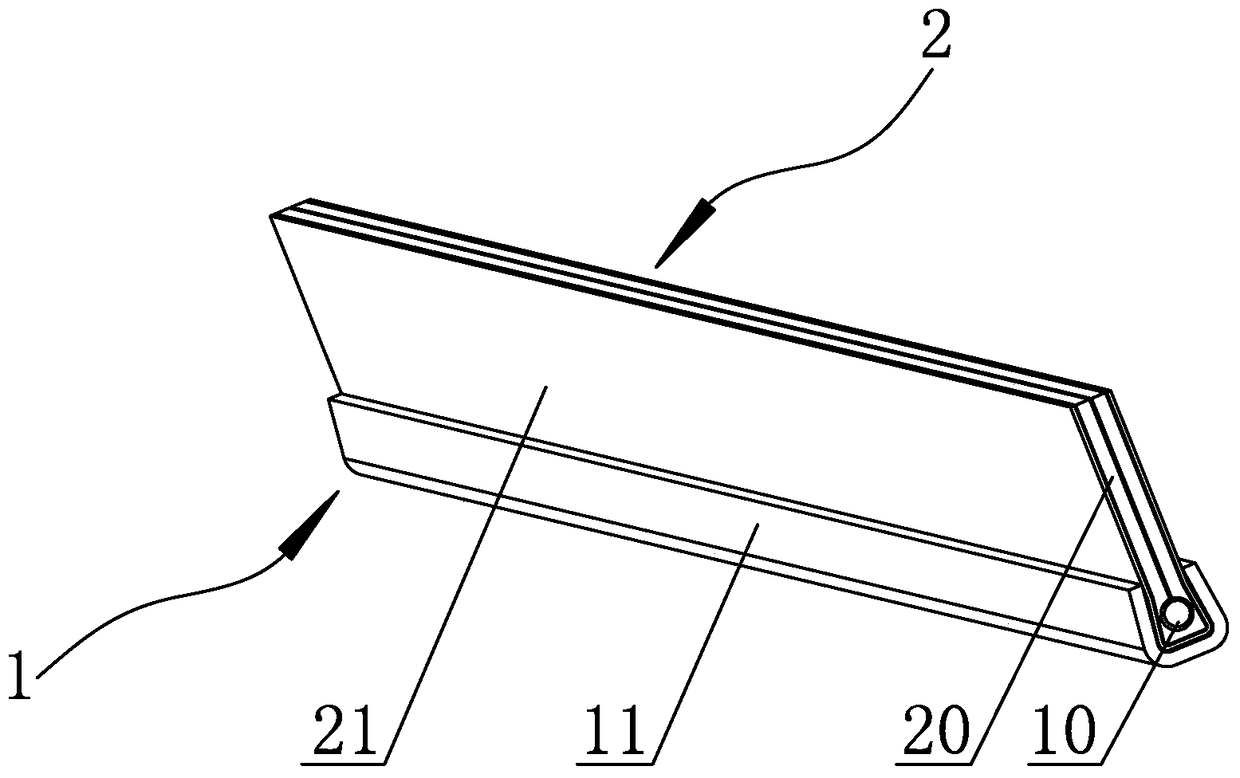

[0032] like Figure 5 , 6 A brush strip shown includes a fixing part 1 and a bristle part 2 . Specifically:

[0033] The fixing part 1 includes a fixing rod and a covering part, wherein: the fixing rod is an iron wire 10; the covering part is an iron sheet 11 with a U-shaped cross section.

[0034] The bristle portion 2 includes a plurality of bristle filaments 20 and a soft sheet 21, the soft sheet 21 adopts PE (polyethylene), the plurality of bristle filaments 20 are distributed along the width direction of the brush, and one end of the plurality of bristle filaments 20 and the soft sheet 21 is It is fixed by the fixing part 1, and the width of the soft sheet 21 is consistent with the distribution width of the plurality of bristle filaments 20, and the other end of the soft sheet 21 is flush with the other end of the plurality of bristle filaments 20.

[0035] In this embodiment: the soft sheet 21 is located among the multiple bristle filaments 20 . The specific structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com