Fluff filter and washing machine with same

A lint filter and filter technology, applied in the field of washing machines, can solve the problems that the advantages of the lint filter cannot be well exerted, hinder, and are not conducive to the collection of lint, and achieve the effect of good filtering effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] A kind of lint filtering device of the present invention is described in detail below in conjunction with accompanying drawing:

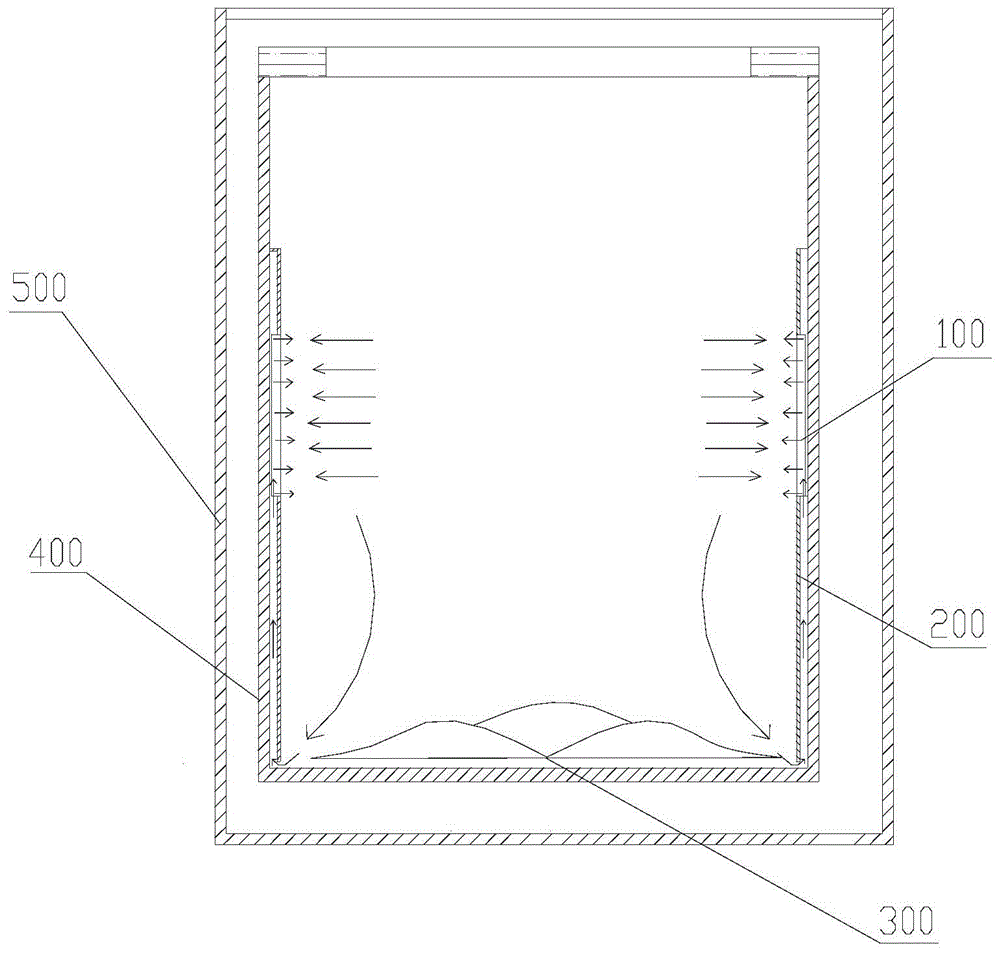

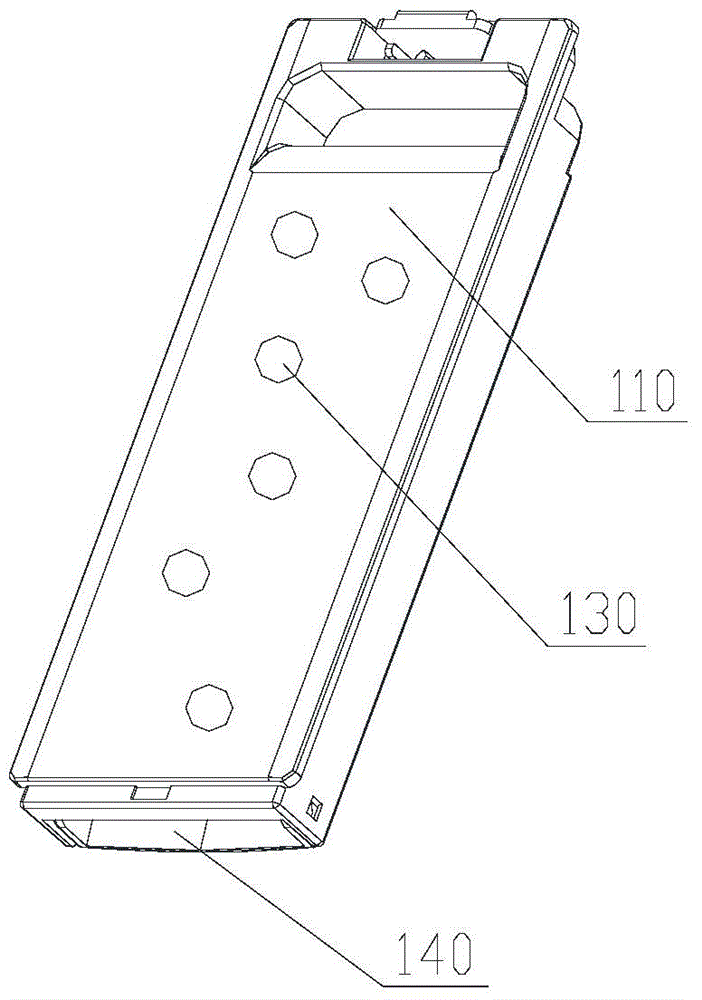

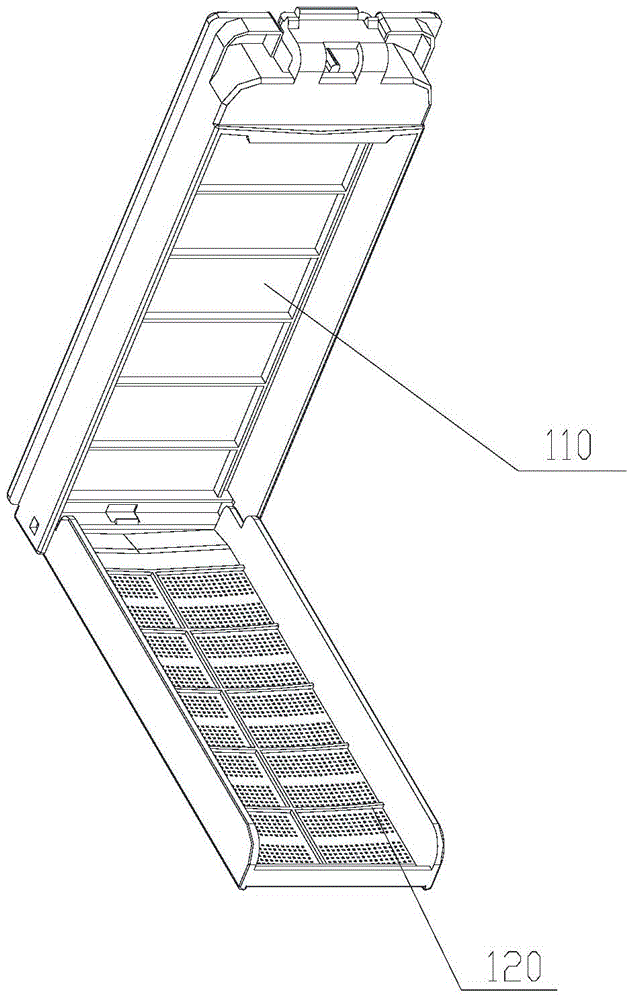

[0036] Such as Figure 6 As shown, the present invention provides a lint filter, the lint filter is installed on the inner barrel 400, the lint filter is closed toward the inner side of the inner wall of the inner barrel 400, and the lint filter faces A filtering portion is provided on one side outside the inner wall of the inner tub 400; the lint filter allows the washing water in the inner tub 400 to be filtered and then discharged to the outside of the inner tub.

[0037] The installation method of the lint filter of the present invention is the same as that of the existing lint filter, but after the lint filter of the present invention is installed on the inner tub of the washing machine, the side facing the inner wall of the inner tub 400 is closed, However, the filtering portion is provided toward the outer side of the inner wall of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com