with bolted segmented rotor blades

A technology of rotor blades and bolts is applied in the field of rotor blades to achieve the effect of good accessibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

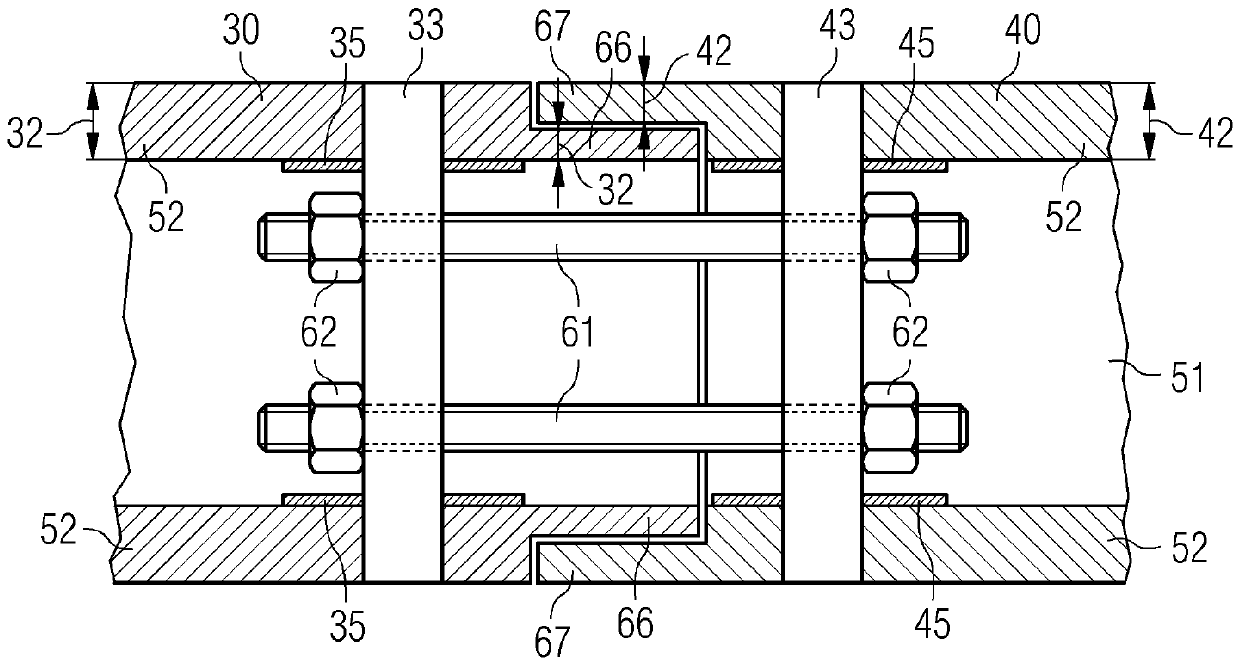

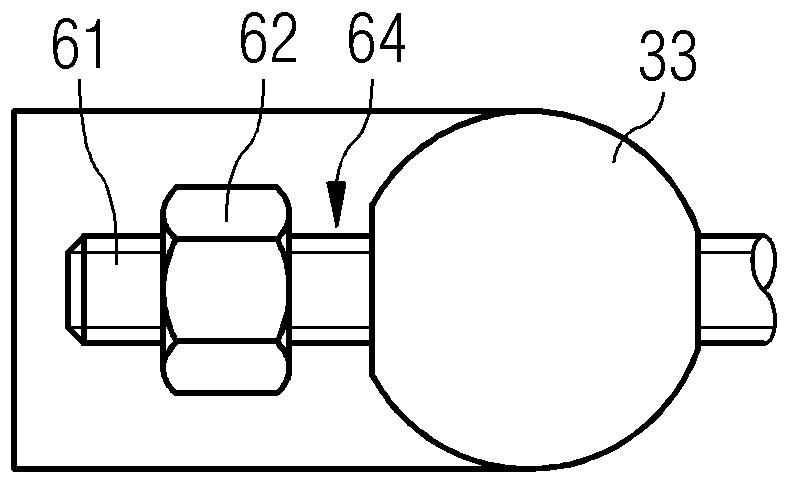

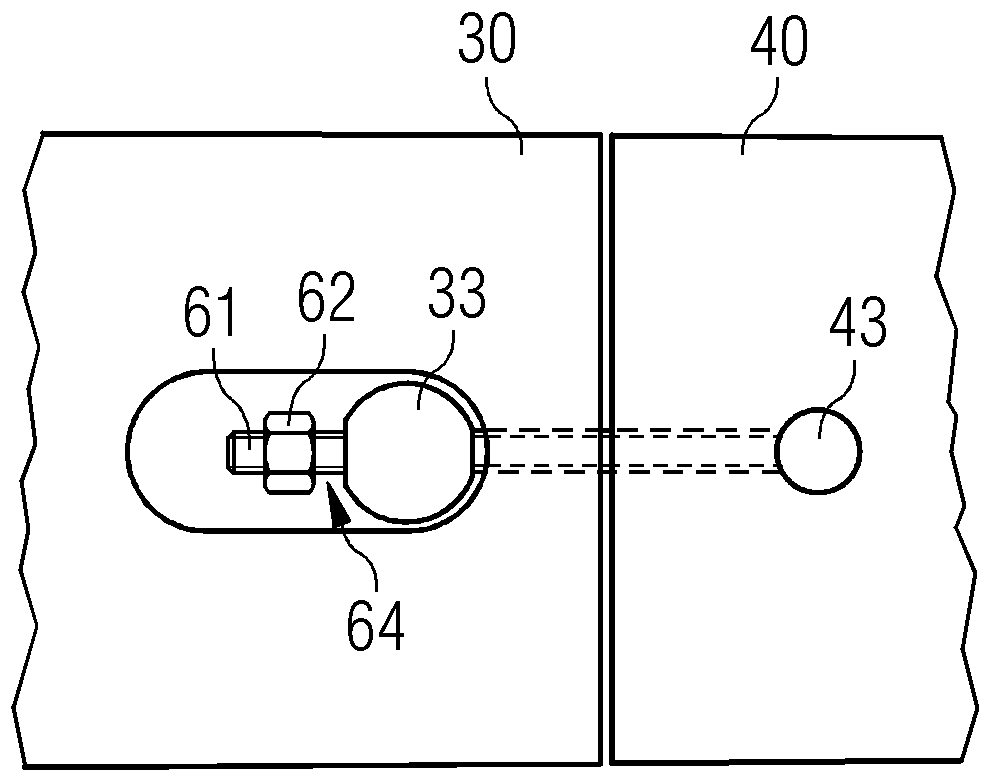

[0082] The illustrations in the figures are in schematic form. It should be noted that in different drawings, similar or identical elements may have the same reference numerals.

[0083] exist figure 1 In , a wind turbine 10 is shown. Wind turbine 10 includes a nacelle 12 and a tower 11 . A nacelle 12 is mounted at the top of the tower 11 . The nacelle 12 is mounted rotatable relative to the tower 11 by means of a yaw bearing. The axis of rotation of the nacelle 12 relative to the tower 11 is called the yaw axis.

[0084] Wind turbine 10 further includes a hub 13 with one or more rotor blades 20 . The hub 13 is mounted rotatably relative to the nacelle 12 by means of main bearings. The hub 13 is mounted rotatably about a rotor axis of rotation 14 .

[0085]Wind turbine 10 further includes a main shaft connecting hub 13 to a rotor of generator 15 . If the hub 13 is directly connected to the rotor, the wind turbine is called a gearless direct drive wind turbine. Alterna...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com