Connection device of thin-wall flexible tube and connection method thereof

A technology for hose connection and connection device, which is applied in the direction of hose connection device, pipe/pipe joint/pipe fitting, mechanical equipment, etc., and can solve the problems of complex pasting process, gaps, and limited clamping effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

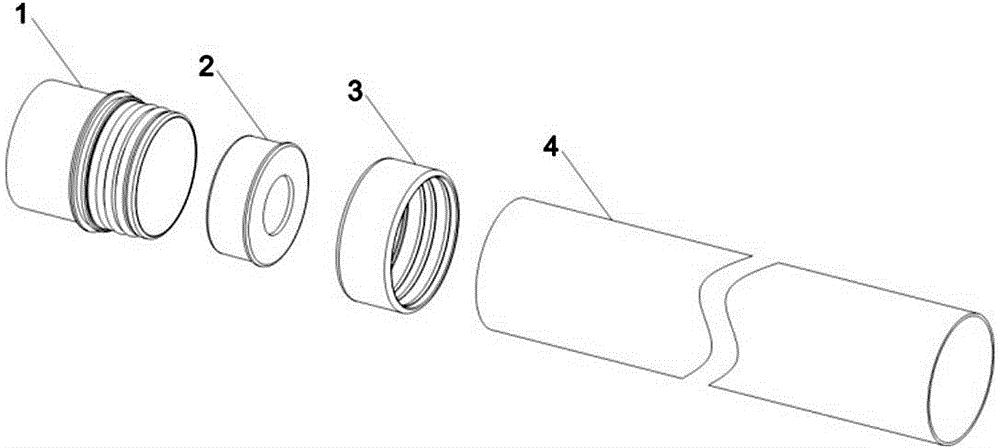

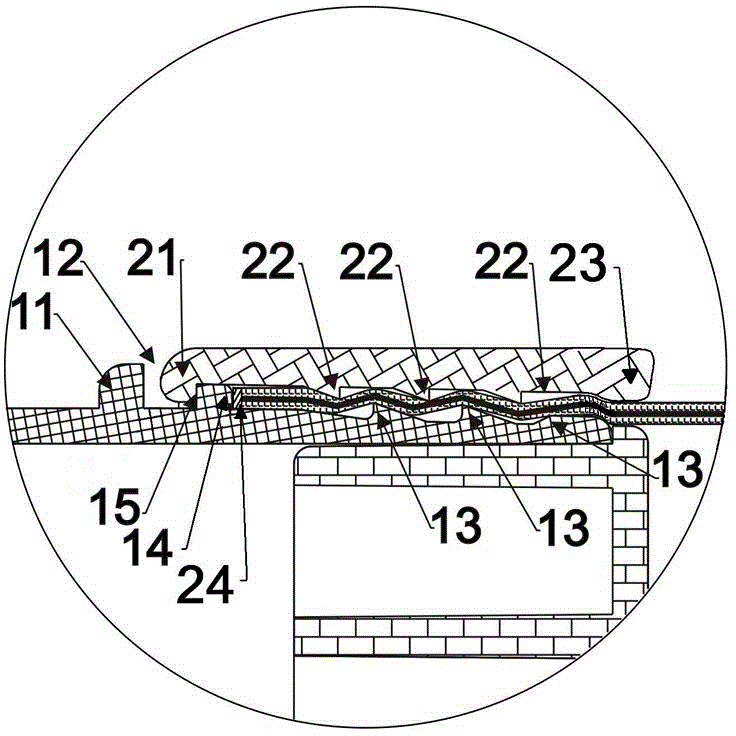

[0044] Embodiment one: refer to figure 1 It is an exploded view of the structure of this embodiment. The hose connection device is composed of a joint 1, a fixed sleeve 2, an outer ring 3 and a hose 4, and the specific connection steps are as follows:

[0045] Step 1: If Figure 5 As shown, before processing, the outer ring 3 is immersed in 100°C water, boiled for 10 hours to make it fully absorb water and swell and become soft, and then put it on the outside of the hose 4;

[0046] Step 2: If Figure 7 As shown, put the hose 4 into the joint, so that the end of the hose 4 is close to the position of the second outer side 14 of the limit baffle;

[0047] Step 3: If Figure 8 As shown, use the processing equipment to push the outer ring 3 to the position of the limit baffle 11;

[0048] Step 4: If Figure 9As shown, after the outer ring enters, it uses the plastic elastic to naturally shrink and clamp the hose, and the inverted tooth that is staggered from the...

Embodiment 2

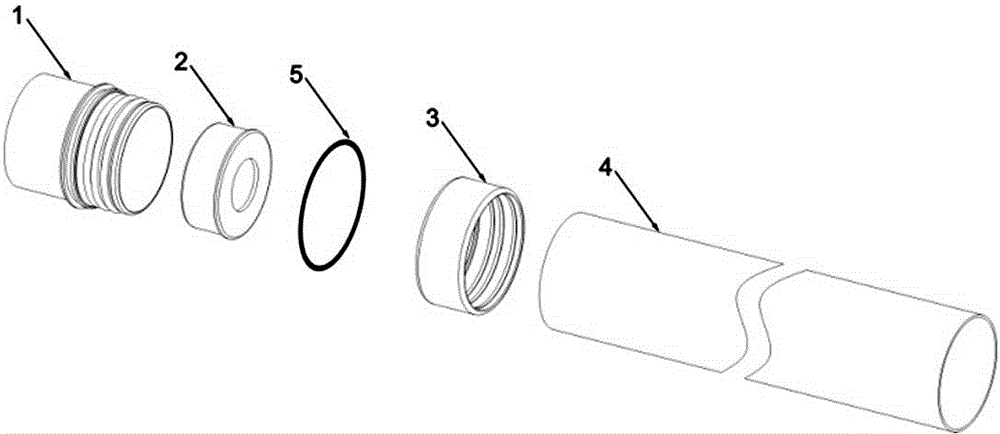

[0050] Embodiment two: refer to figure 2 It is an exploded view of the structure of this embodiment. The hose connection device is composed of a joint 1, a solid sleeve 2, an outer ring 3, a hose 4 and a sealing ring 5, and the specific connection steps are as follows:

[0051] Step 1: If Image 6 As shown, before processing, immerse the outer ring 3 in water at 100°C and cook for 12 hours to make it fully absorb water and swell and become soft. sealing ring 5;

[0052] Step 2: If Figure 7 As shown, put the hose 4 into the joint, so that the end of the hose 4 is close to the position of the second outer side 14 of the limit baffle;

[0053] Step 3: If Figure 8 As shown, use the processing equipment to push the outer ring 3 to the position of the limit baffle 11;

[0054] Step 4: If Figure 9 As shown, after the outer ring enters, the plastic elastic is used to naturally shrink and clamp the hose, and the inverted tooth that is staggered from the joint cla...

Embodiment 3

[0058] Embodiment three: refer to Figure 10 This connection device is applied to the structure diagram of the goal. The connecting part of the two posts of the goal adopts the connection device introduced by the present invention, and the goal post adopts the flexible pipe introduced by the present invention. Inflate the valve so that the hose is full, giving Figure 10 The goal shown in the figure; when not in use, release the gas in the hose and put it in a bag after compression, which is light in weight, does not take up space and is easy to carry. Since the doorpost adopts an inflatable hose, it has a cushioning effect when a person bumps into it and will not be injured.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com