Automatic boring equipment for engine cylinder head

An engine cylinder, drilling equipment technology, applied in drilling/drilling equipment, boring/drilling, metal processing equipment and other directions, can solve the problems of inconvenient operation, low production efficiency, time-consuming, etc., to ensure smoothness and dimensional accuracy, stable and reliable clamping, and the effect of speeding up production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

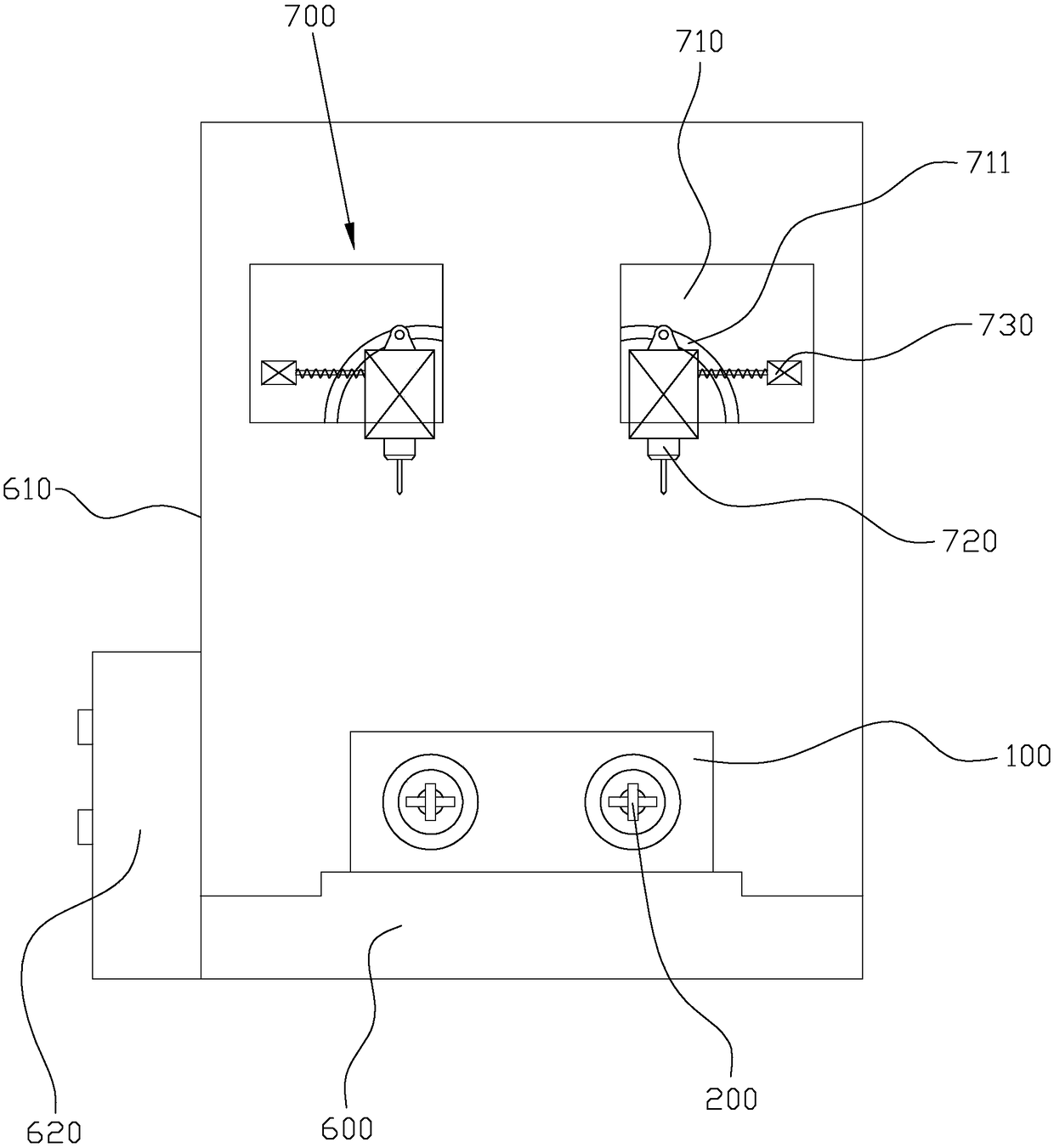

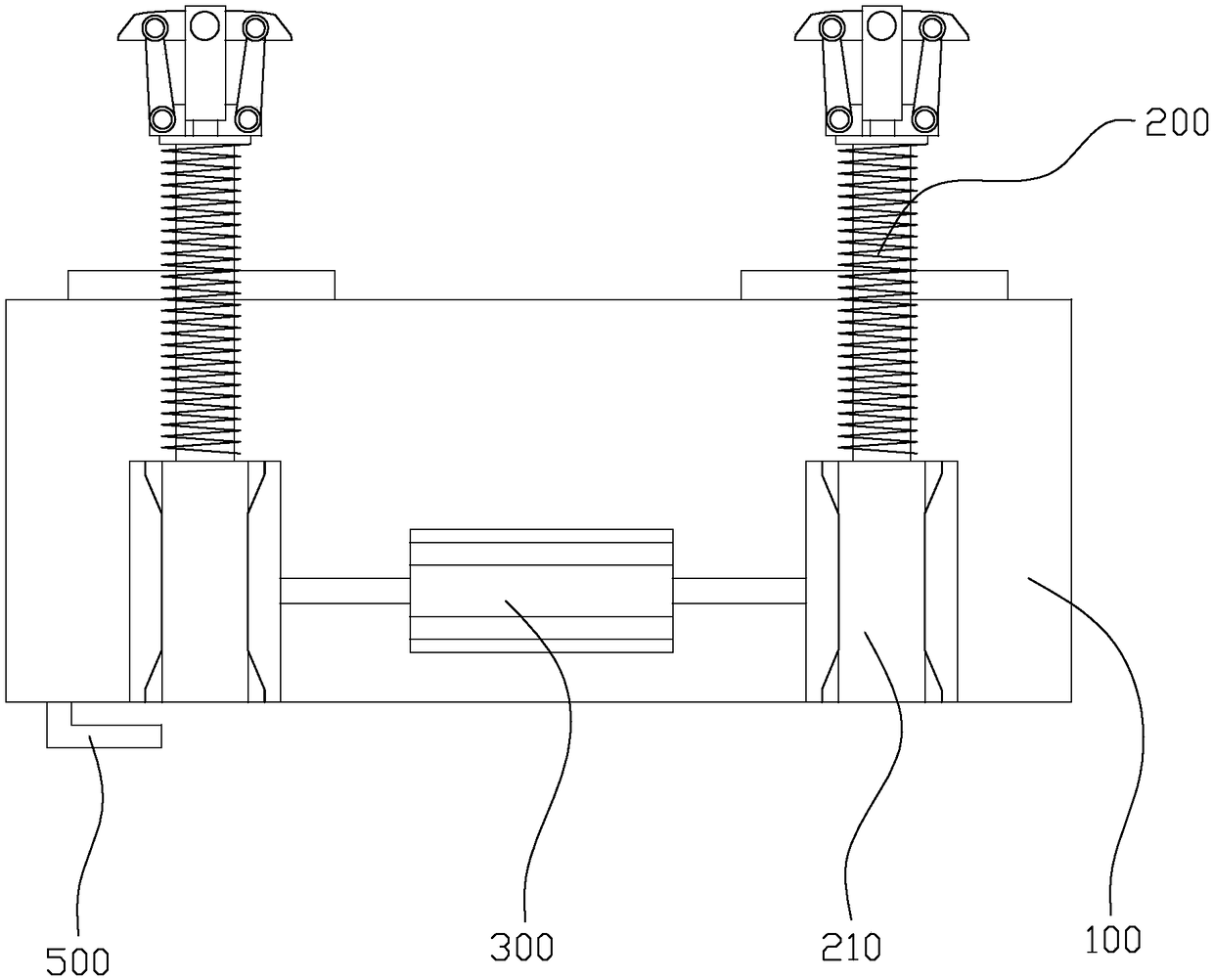

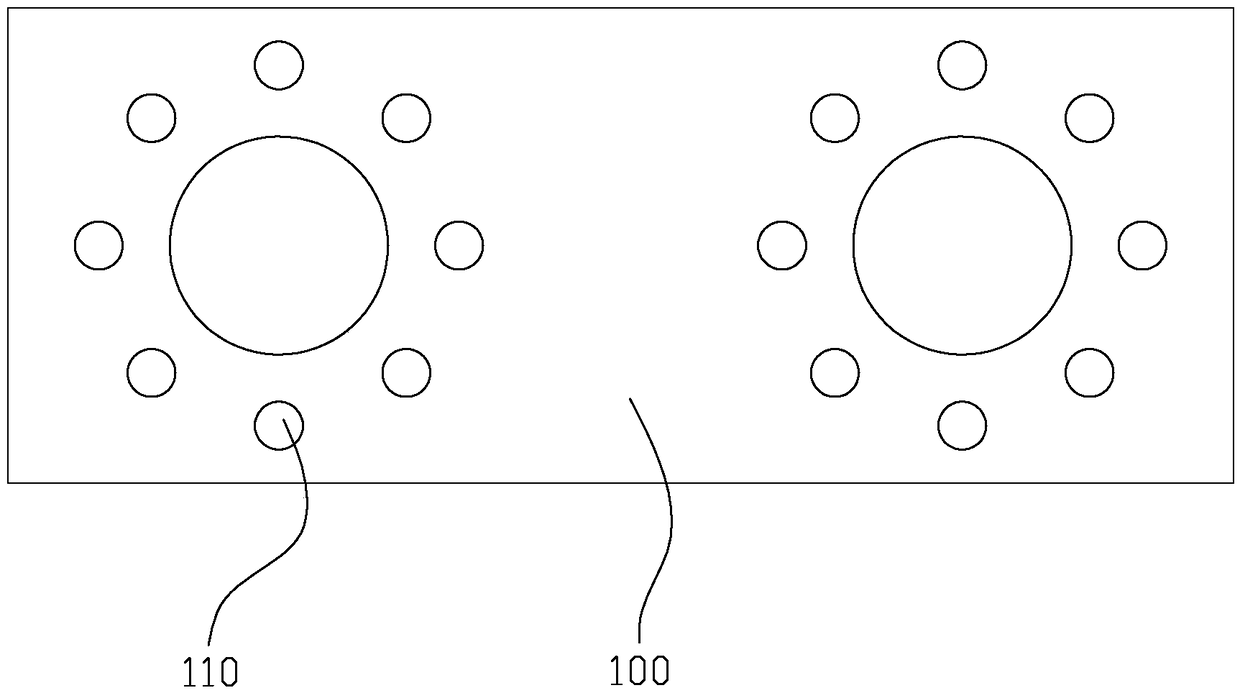

[0020] refer to Figure 1 to Figure 4 , an embodiment of the present invention provides an engine cylinder head automatic drilling equipment, including a main frame 600, the main frame 600 is provided with a clamp, two sets of drill assemblies located above the clamp, and an outer casing 610, the drill The assembly includes a mounting frame 710, a drill bit 720 and a driving device 730. The middle part of the drill bit 720 is hinged on the mounting frame 710. The mounting frame 710 is provided with an arc-shaped groove 711. The slider in the arc-shaped groove 711, the driving device 730 is connected to the drill bit 720 and drives the drill bit 720 to swing; the clamp includes a base 100, two locking assemblies 200 and a steering device 300, and the locking assembly 200 includes a telescopic cylinder 210, a guide sleeve 220, a telescopic rod 230 and two locking blocks 240, the guide sleeve 220 is fixed on the telescopic cylinder 210, and the telescopic rod 230 is connected thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com