Electric sprayer nozzle

A technology of electric sprayer and spray head, which is applied in the direction of spraying device, liquid spraying device, etc., which can solve the problems of not being able to pump several barrels of medicine, labor and time-consuming, and short continuous operation time, and achieve the effect of preventing water ingress and solving malfunctions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

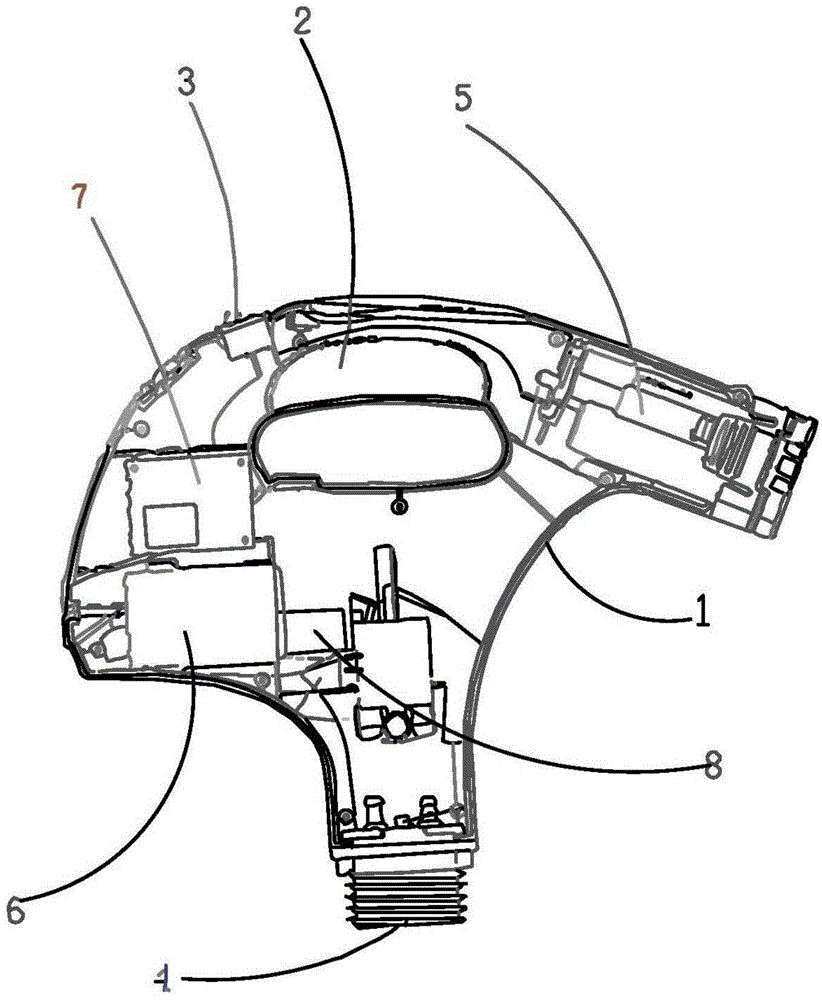

[0016] A kind of electric atomizer nozzle of the present embodiment, as figure 1 As shown, the nozzle head of the electric sprayer is fixed to the water tank through the bayonet 4. The nozzle head of the electric sprayer includes a housing 1, an air pump 6 fixed on the housing 1, a battery 5 and a main control board 7, and the inside of the outlet of the air pump 6 is provided with a pressure The sensor 8 and the pressure sensor 8 are connected to the bayonet 4 through a hose; the battery 5 is used to supply power to the air pump 6, the main control board 7 and the pressure sensor 8; the air inlet of the air pump 6 communicates with the atmosphere, and the air outlet of the air pump 6 Set on the bayonet 4 and connect with the water tank; the signal input end of the main control board 7 is connected with the output end of the pressure sensor 8, and the control output end of the main control board 7 is connected with the control end of the air pump 6; the hose is located at the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com