Wind power blade transport cart of improved turnover plate mechanism

A technology of wind turbine blades and flap mechanism, which is applied in the direction of vehicles used to carry long goods, which can solve the problems of reducing the balance during rotation, increasing the transportation pressure, and the heavy weight of the counterweight, so as to improve the balance and safety High performance, shortened telescopic stroke, and energy-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The wind power blade mountain transport vehicle disclosed in the present invention will be further described below in conjunction with specific implementation methods:

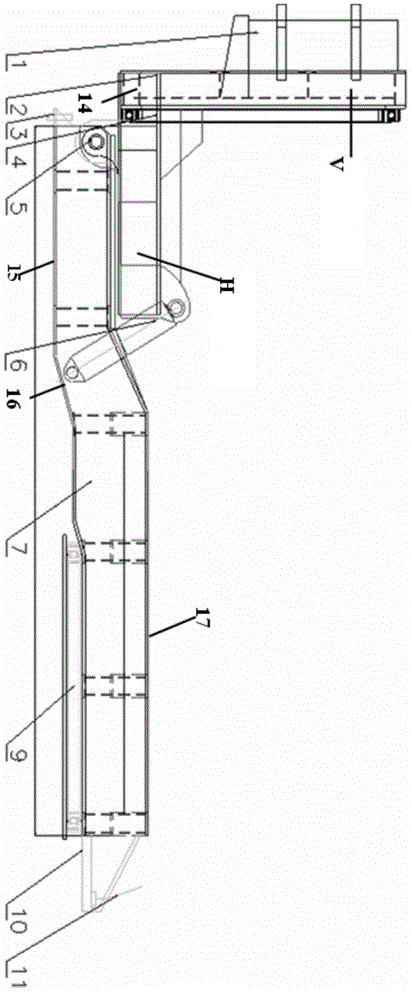

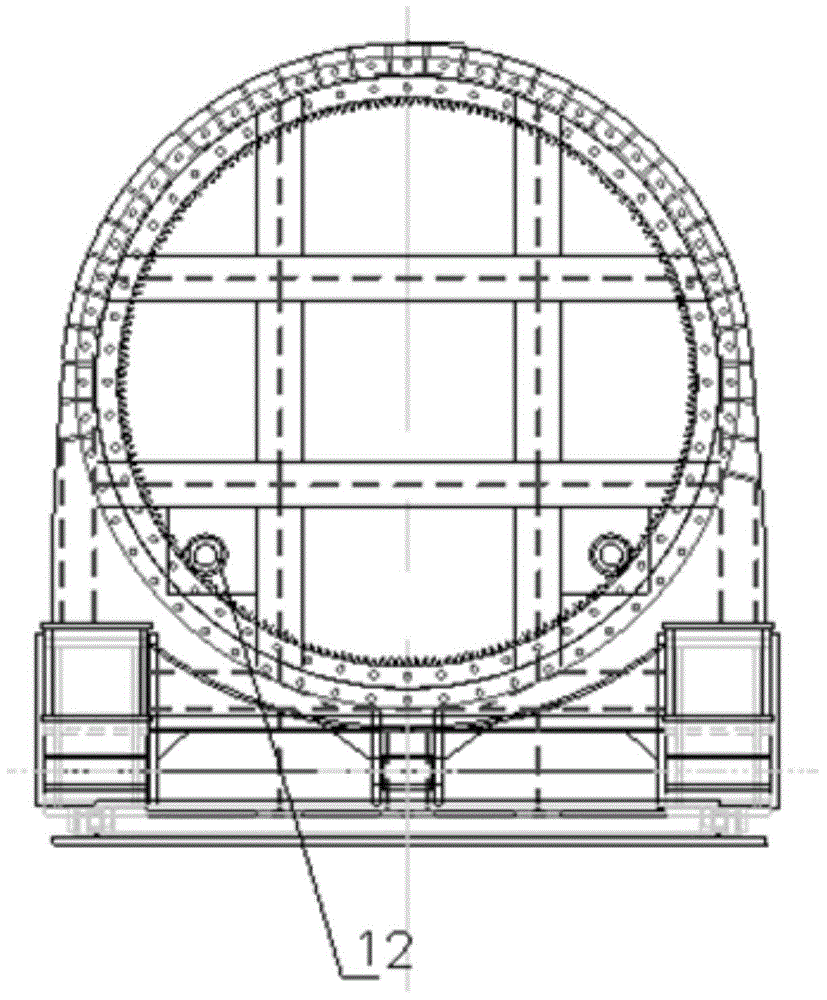

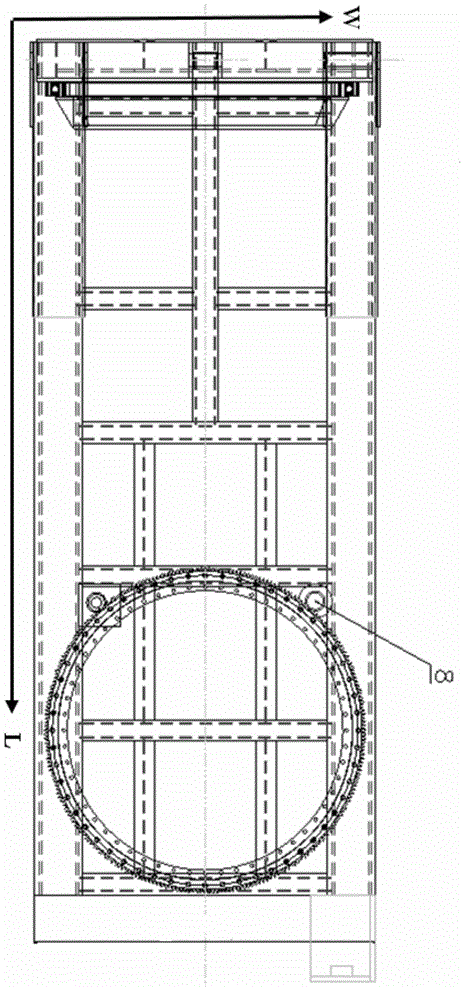

[0036] Such as Figure 1-3 As shown, the wind power blade mountain transport vehicle with the lifting device of the present invention includes: a main beam 7, an L beam flap 2, and a hinge portion 5, and the L beam flap 2 includes a horizontal section H and a vertical section V, The horizontal section H and the vertical section V of the L-beam flap have a connecting portion 14, and a flap counterweight 1 is installed on the vertical section V of the L-beam flap. See attached image 3 , the main girder 7 is roughly rectangular in shape when viewed from a top view, including a width direction L and a length direction W, see the attached figure 1, the main beam 7 along the length direction L is followed by a first horizontal section 15, an inclined section 16 and a second horizontal section 17, wherein t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com