Material grabbing, lifting and translation device for truss truck

A translation device and material technology, applied in the field of transmission machinery, can solve the problems of easy left and right swing, the lifting speed is not stable enough, and it is not easy to accurately locate, and achieves the effects of improving reliability, improving rigidity and increasing work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

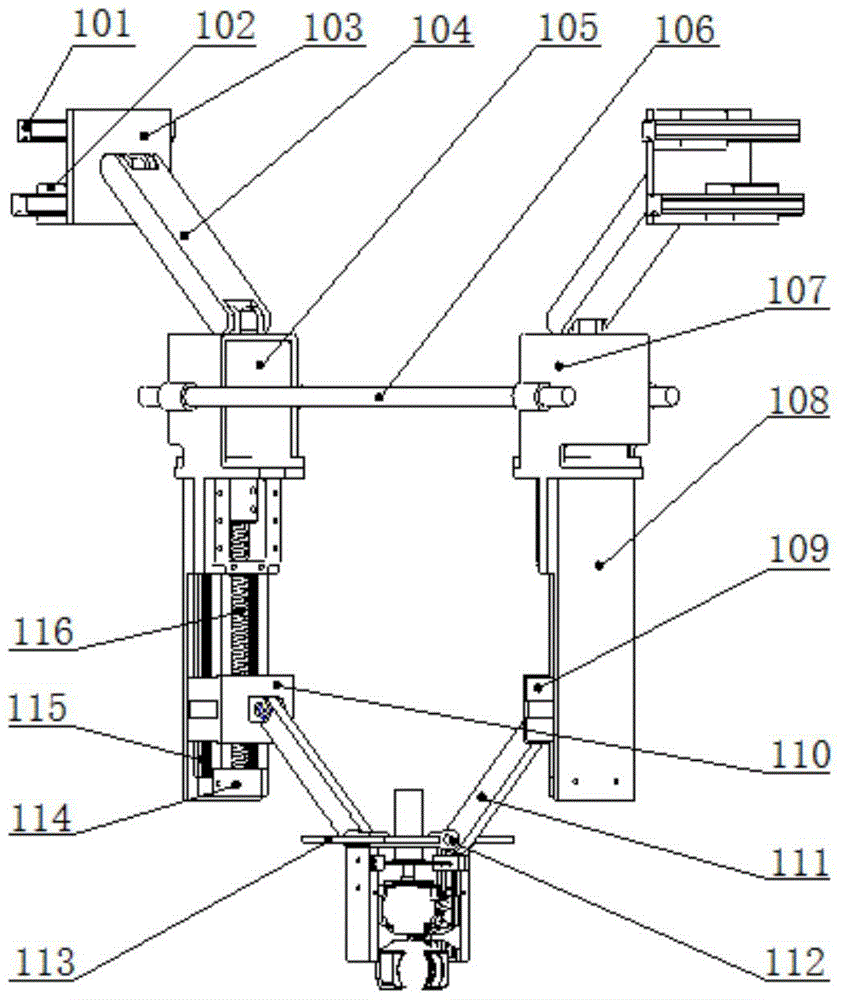

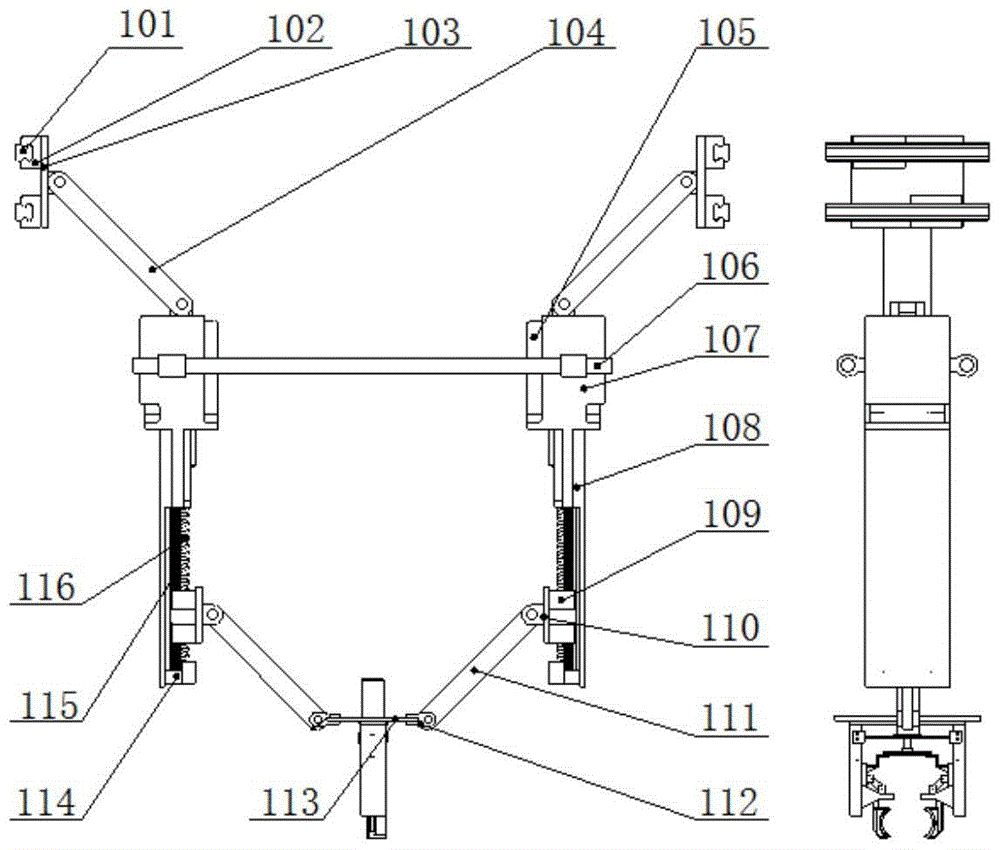

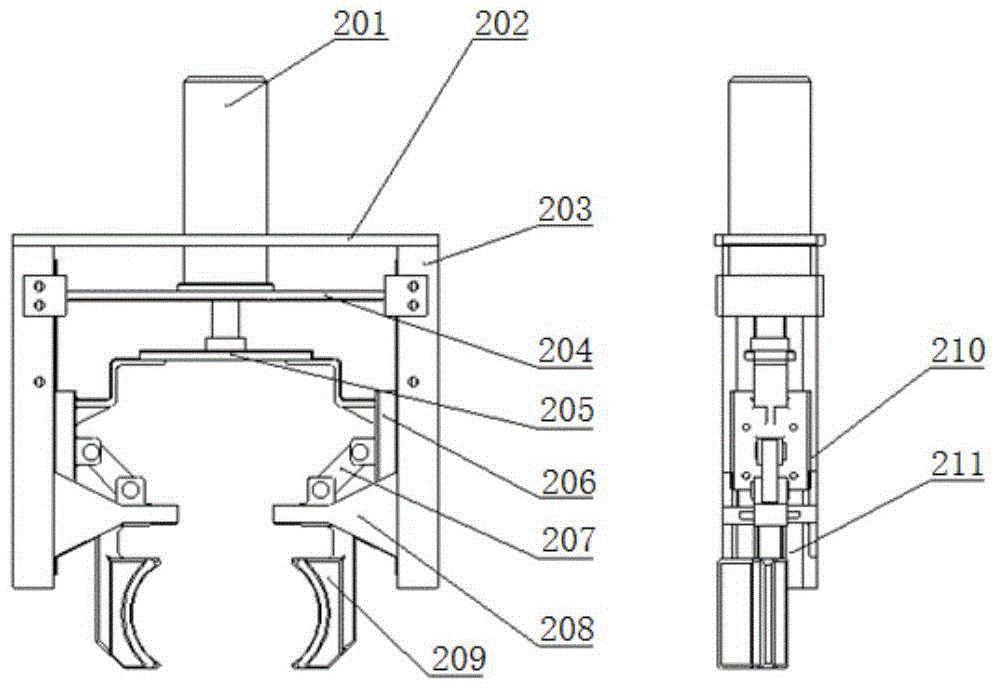

[0017] Such as figure 1 , figure 2 As shown, a material grabbing lifting translation device suitable for truss vehicles includes two translation guide rail devices arranged in parallel, a left vertical lifting device, a right vertical lifting device, a grabbing manipulator, a moving platform pin lug 112, and a moving platform 113 , the left vertical lifting device is connected with the right vertical lifting device through the guide shaft 106, one end of the left and right vertical lifting device is respectively connected with the corresponding translation guide rail device through the forearm 104, and the other end is respectively connected with the respective translation guide rail device through the connecting rod 111. Corresponding moving platform pin lug 112 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com