Discharging platform construction method

A technology of a discharge platform and a construction method, which is applied in the processing of building materials, house structure support, house structure support and other directions, can solve the problems of complicated positioning of reserved holes, inconvenient installation of the discharge platform, and poor quality of reserved holes. , to achieve the effect of saving construction steps, saving resources and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

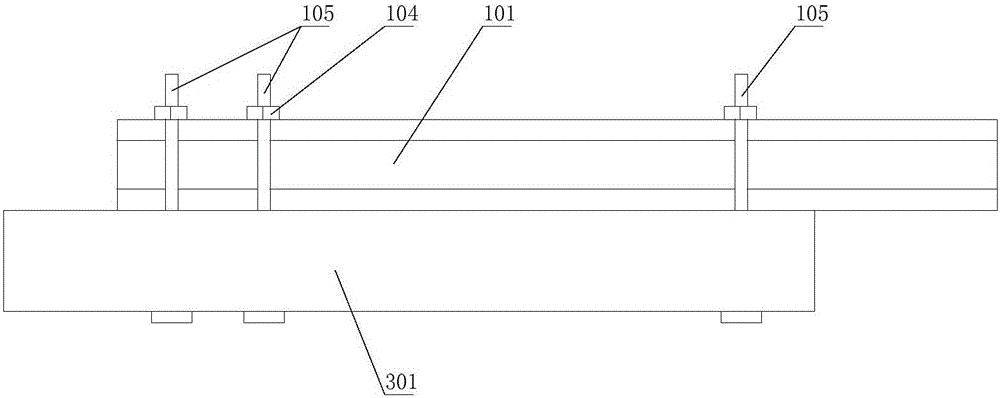

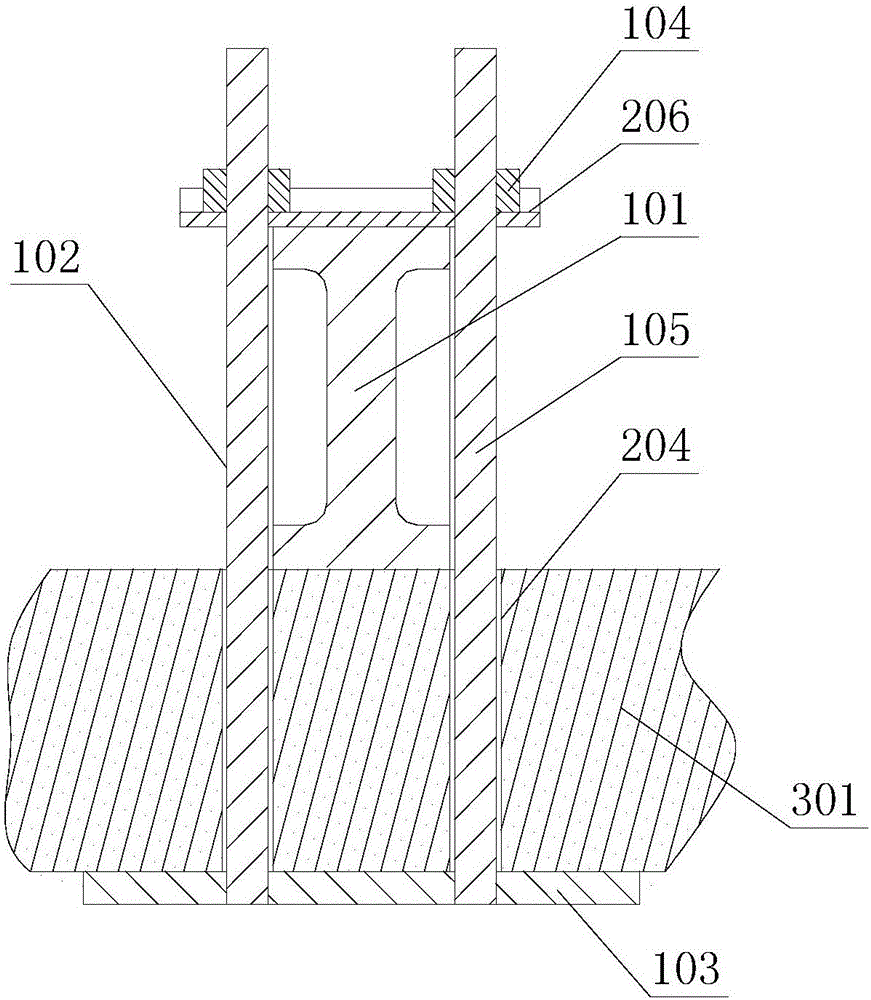

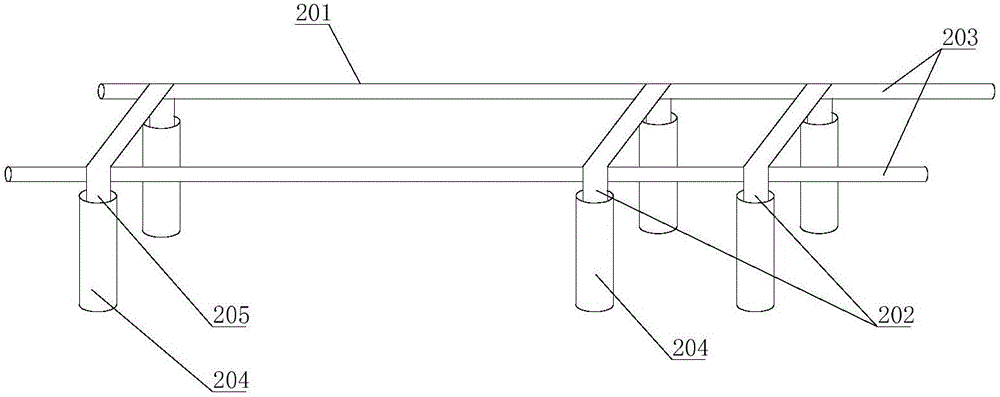

[0036] In order to facilitate the installation of the unloading platform during construction, it is necessary to set reserved holes in the concrete floor. For the setting of the existing reserved holes, before pouring the concrete slab, use measuring tools such as a tape measure or a tape measure to locate the reserved holes on the formwork, and then install plastic pipes or steel pipes at the positioning positions. After the concrete slab is poured, that is, A reserved hole can be formed. There are a large number of reserved holes, which require multiple measurements. The operation is complicated and the error is large. As a result, after the pouring is completed, the positions of the reserved holes change, and the installation of the unloading platform is inconvenient.

[0037] In view of this, the designer of the present invention designed a construction method for the unloading platform. The positioning operation of the reserved holes is simple, which saves construction ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com