Bellows seal fittings with shielding

A technology for sealing joints and bellows, which is applied in the direction of protective grounding/shielding devices, bases/shells, etc. of connecting parts, which can solve the problems of weakened EMC performance, limited outer diameter size, and insufficient sealing performance to achieve good EMC resistance. performance, meet the miniaturization design, improve the effect of the common ground effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with drawings and embodiments.

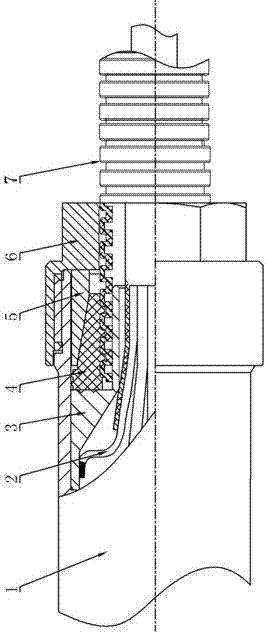

[0017] Such as figure 1 As shown, the sealing joint is used to connect the sensor housing 1 and the bellows 7 , and the sealing joint includes a shielding ring 3 , a sealing ring 4 , a compression ring 5 and a compression nut 6 .

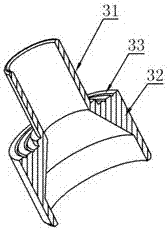

[0018] The structure of the shielding ring 3 is as follows figure 2 As shown, the shielding ring 3 is composed of a cylinder connected to the front and rear ends, the front end is the shielding end 32, the inner wall is welded to the shielding wire 2, the outer wall of the front end is in transition or interference fit with the sensor housing, and the outer diameter of the front end is larger than that of the rear end. Large, the rear end is a support end 31, and the support end 31 is used to support the bellows 7 to prevent the bellows 7 from being deformed by the extrusion of the sealing ring 4. There is an annular groove 33 on the eleva...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com