Rotary panel structure

A technology of panels and rotating centers, applied in the direction of cabinets/cabinets/drawer parts, etc., can solve the problems of poor independent maintenance, inconvenience, long time for disassembly or maintenance operations, etc., and achieve the effect of large maintenance space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

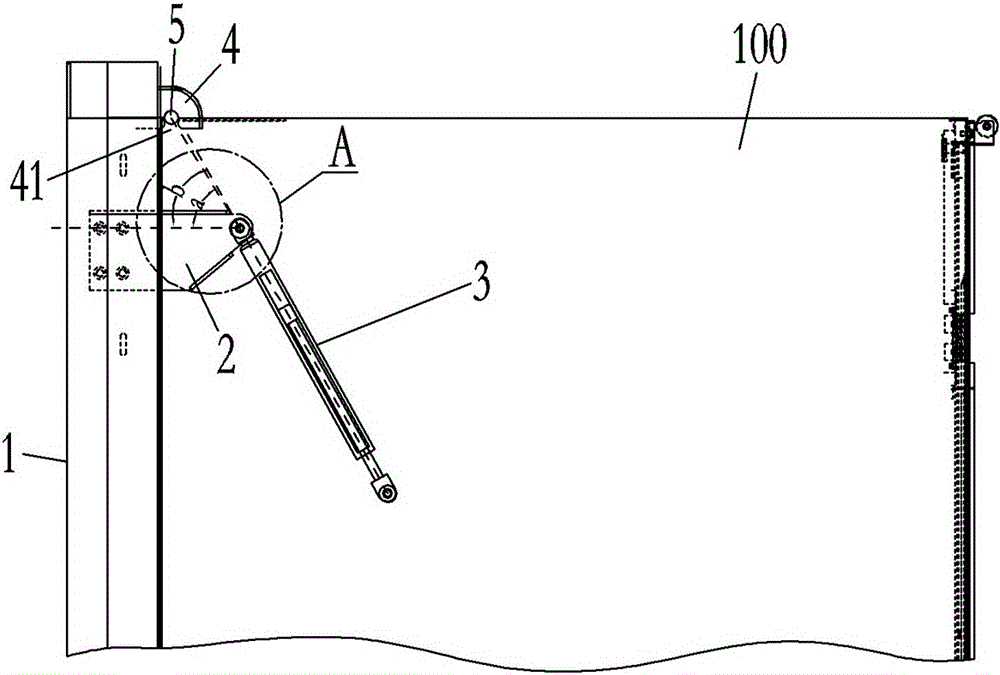

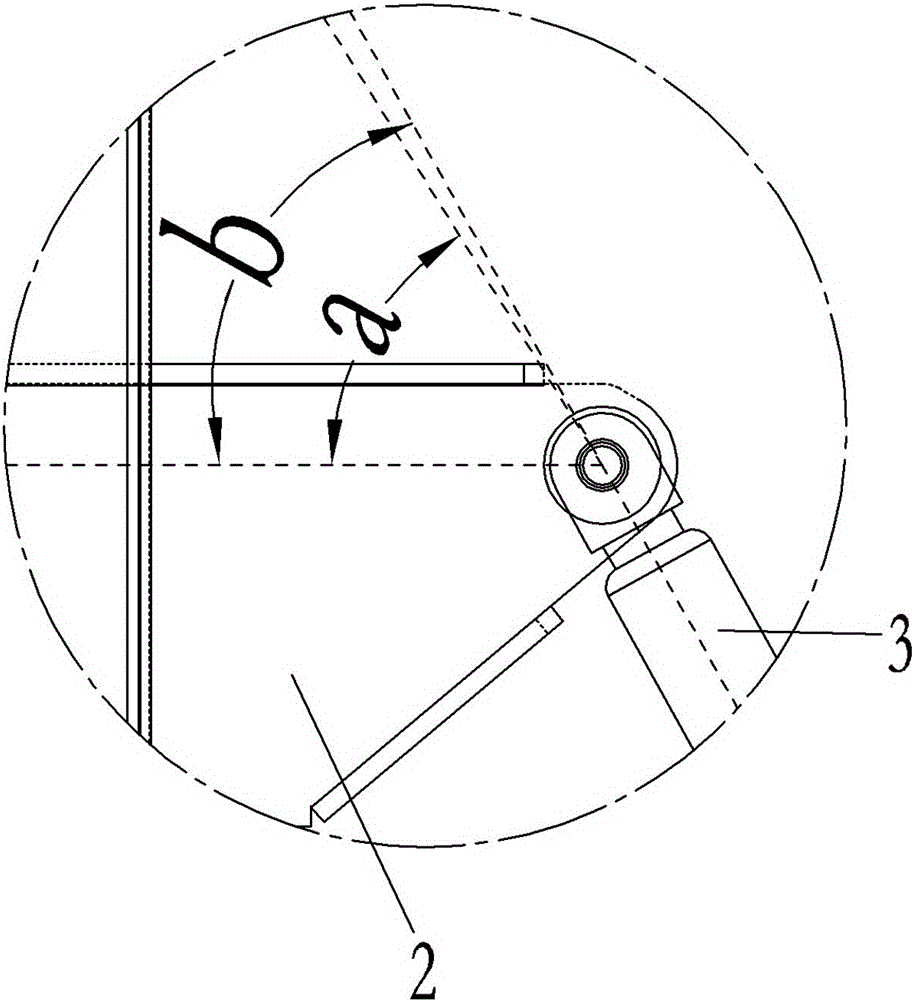

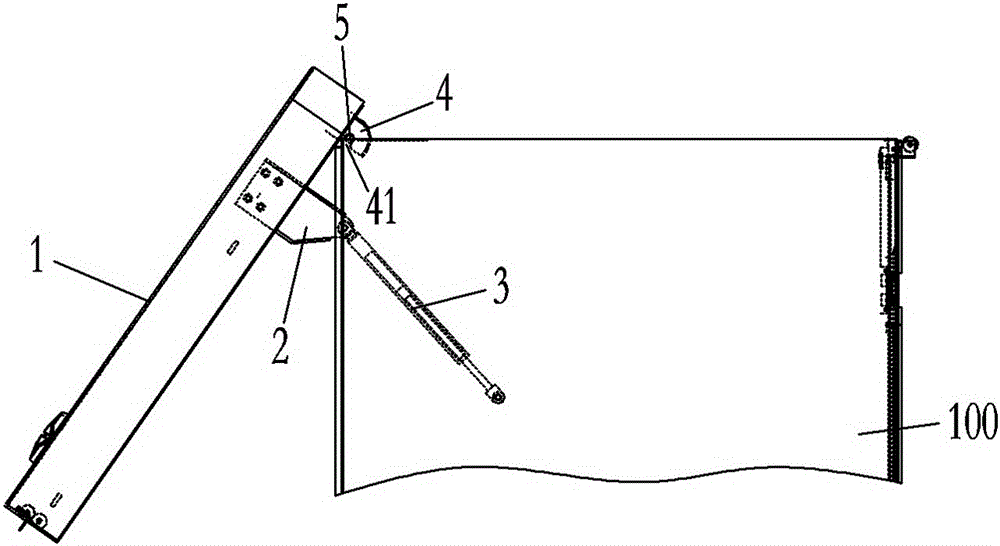

[0012] Such as Figures 1 to 6 As shown, the rotating panel structure includes a panel 1, the top of the panel 1 is rotatably connected to the top front edge of the cabinet 100, and can swing up and down around its rotation center, and the panel 1 is located below its rotation center The hinge seat 2 extending backward is fixed, one end of the gas spring 3 (that is, the end of the pressure rod of the gas spring 3 or the end of the piston rod) is hinged with the hinge seat 2, and the other end (that is, the end of the piston rod of the gas spring 3) end or the end of the pressure rod) is hinged inside the cabinet 100, when the panel 1 is not turned up, the angle b between the thrust direction of the gas spring 3 acting on the hinge seat 2 and the normal line of the panel 1 is slightly larger than the hinge seat The included angle a between the line connecting the center of rotation of 2 and the center of rotation of panel 1 and the normal line of panel 1; The spring 3 can auto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com