High-density caged-chicken coop three-stage environment control system

A control system, three-stage technology, applied in the field of poultry breeding industry, can solve the problems of uneven distribution of wind speed and temperature, poor effect, etc., and achieve the effect of avoiding cold stress, environmental control and low-carbon emissions, and excellent equipment production and installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

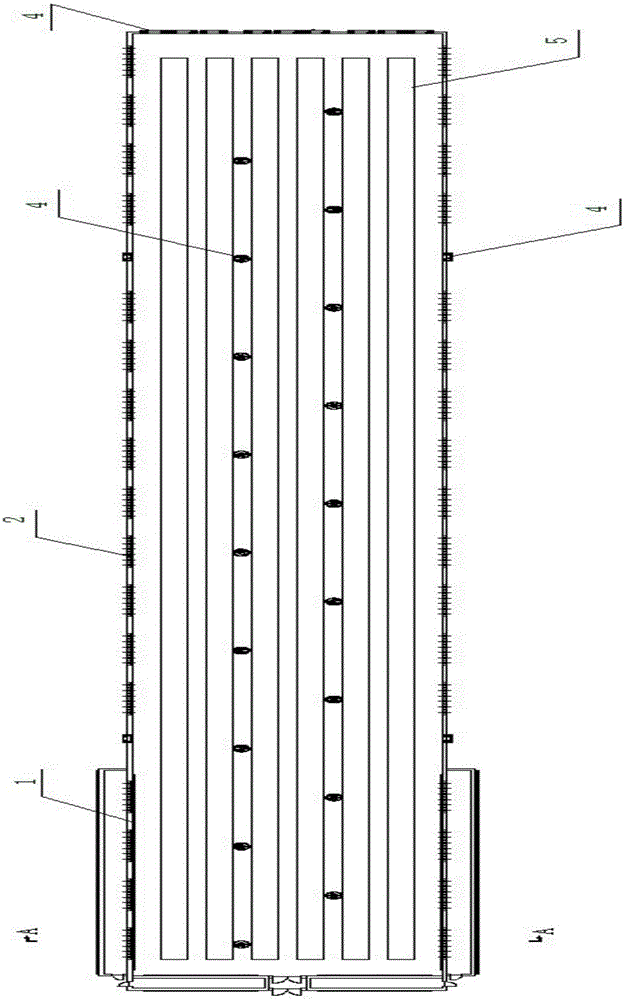

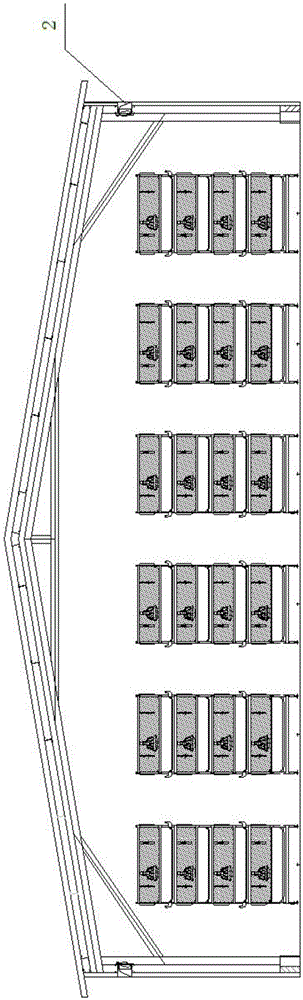

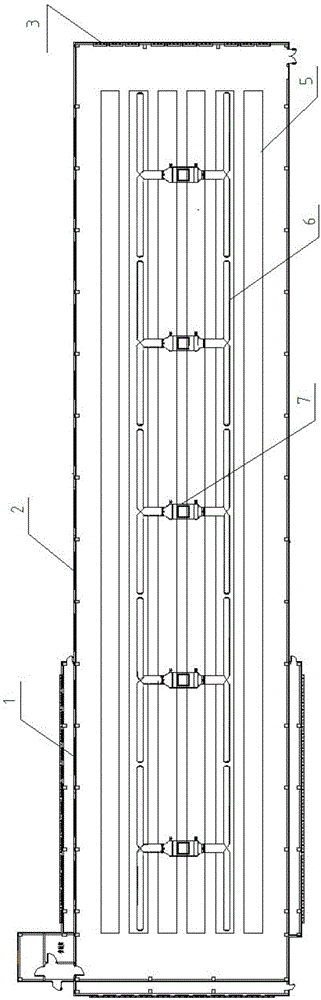

[0025] Such as Figure 3-4 As shown, the three-stage environment control system of the high-density caged chicken house of the present invention includes a caged chicken house body, and several rows of cage assemblies are arranged in the interior of the caged chicken house body, and the cage assembly consists of several The layer cage consists of 5 layers. The left end side wall of the caged chicken house body is provided with several left air inlet windows, and the right end side wall of the caged chicken house body is provided with several right end exhaust fans 4; The front end of the wall is symmetrically provided with several front air intake windows 1, and the middle part to the rear end of the two side walls of the caged chicken house body is all symmetrically provided with several small side wall air intake windows 2.

[0026] It includes a plurality of air m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com