A diffusion tower for mine return air heat exchange

A mine return air and diffusion tower technology, which is used in mine/tunnel ventilation, mining equipment, earth-moving drilling, etc. effect of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

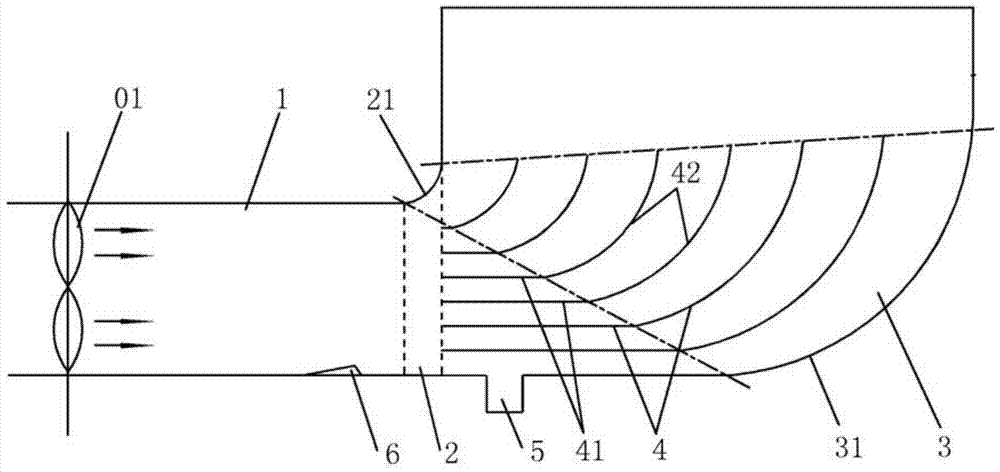

[0016] Such as figure 1 , including a round pipe section 1, a connecting section 2 and an elbow section 3 connected in sequence with the main fan fan 01, and several deflectors 4.

[0017] The circular pipe section 1 can be linear or gradually expanding, and the length of the circular pipe section 1 is equal to 1 to 2 times the diameter of the circular pipe. The connecting section 2 is a gradually expanding circular-to-square joint, and the circular area of its air inlet is smaller than the rectangular area of its air outlet. , The inner arc 21 of the connecting section 2 is a 90-degree arc-shaped steel plate. The elbow section 3 is a right-angle elbow with an inner straight line and an outer arc. The outer arc 31 of the elbow section 3 is a 90-degree arc-shaped steel plate. The top air outlet can be connected with an external return air heat e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com