Steam compression type air conditioning system

An air-conditioning system and a compression-type technology, which are applied in the field of vapor-compression air-conditioning systems, can solve the problems of large refrigerant and heating differences in charging capacity, difficult working conditions of cooling and heating air conditioners, etc., and achieve the effect of improving the energy efficiency ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The vapor compression air-conditioning system of the present invention includes a connected compressor and an evaporator, as well as a variable container, a temperature difference monitor and a valve control device.

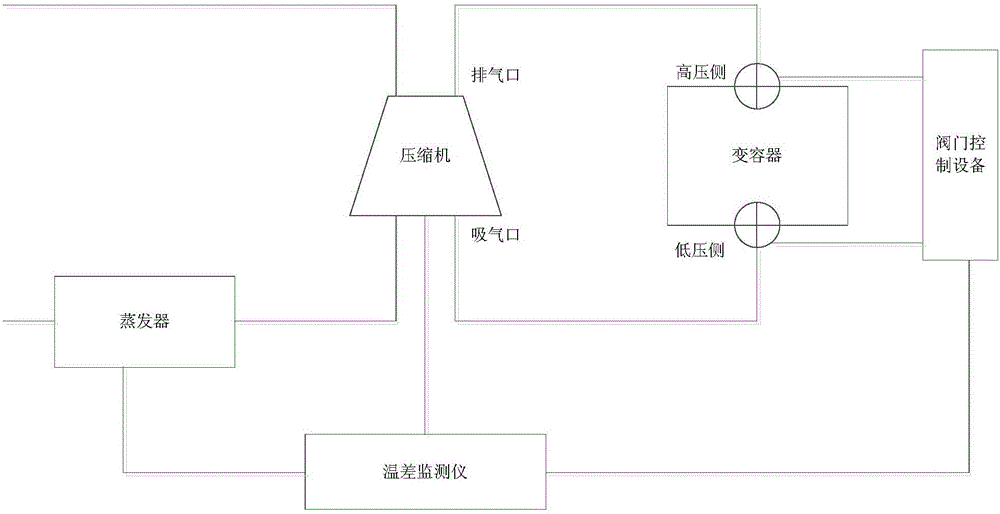

[0020] Such as figure 1 As shown, the high-pressure side of the variable vessel communicates with the discharge port of the compressor for receiving excess working fluid in the compressor, and the low-pressure side communicates with the suction port of the compressor for returning the working fluid to the compressor. In addition, the variable vessel also uses valves to control the on-off of the high-pressure side and the low-pressure side, that is, valves are respectively set on the high-pressure side and the low-pressure side. quality container. The temperature sensor of the temperature difference monitor, one is set at the air inlet of the compressor, and the other is set in the evaporator, the output terminal of the temperature difference monitor is co...

Embodiment 2

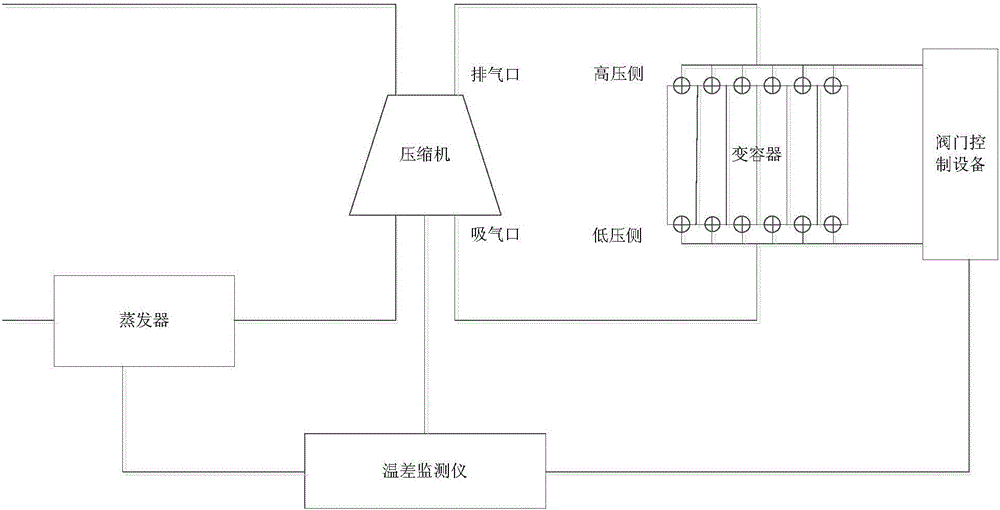

[0025] The vapor compression air-conditioning system of this embodiment is based on the first embodiment, and the variable capacitor is improved. Specifically, multiple partitions are used to divide the variable container into multiple spaces, such as figure 2 As shown, each space is provided with a valve on the high-pressure side and low-pressure side, and a part of the space is used as a space for storing working fluid. In this part of the space, the valve on the high-pressure side is opened, and the valve on the low-pressure side is closed; the other part of the space is used as a space for releasing the working fluid. In this part of the space, the valve on the low-pressure side is opened, and the valve on the high-pressure side is closed.

[0026] In this embodiment, the integrated space of the variable vessel is divided into multiple independent spaces, and a group of high and low pressure side valves are set for each space to control them separately, in order to preven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com