Machining method of light billboard splicing piece

A processing method and billboard technology, which can be applied to signs, instruments, display devices, etc., can solve the problems of waste of resources, high manufacturing cost of billboards, large wind impact, etc. broken effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

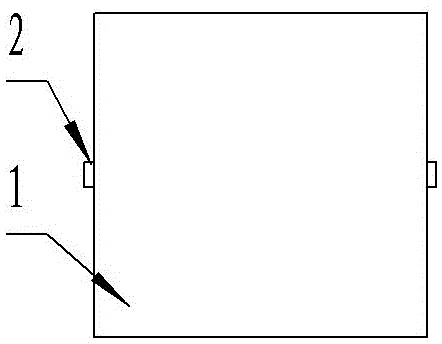

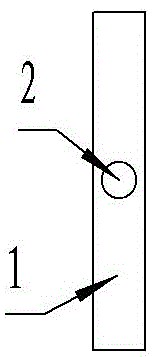

[0015] The processing method of the light-duty billboard splicing piece comprises using and processing a kind of light-duty billboard splicing piece; figure 1 , figure 2 The light-duty billboard splicing piece shown includes a square board body 1, the board body 1 is made of plastic material containing 65% to 70% polytetrachlorethylene, and a rotating shaft 2 is arranged in the middle of each board body, and the board body 1 The body 1 and the rotating shaft 2 are integrally formed, the two ends of the rotating shaft 2 protrude from the plate body 1, and the patterns on both sides of the plate body 1 are symmetrical and consistent; one end of the rotating shaft 2 can be connected to the driving shaft of a fan, and the plate body 1 drives the rotating shaft 2 to rotate. Wind turbines can generate electricity.

[0016] Its processing methods inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com