A laminated spiral magnetic propeller

A screw-type propeller technology, applied in the direction of propulsion systems, electrical components, electromechanical devices, etc., can solve problems such as thrust reduction, achieve the effects of reducing energy consumption, convenient processing and manufacturing, and realizing long-distance propulsion with high thrust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

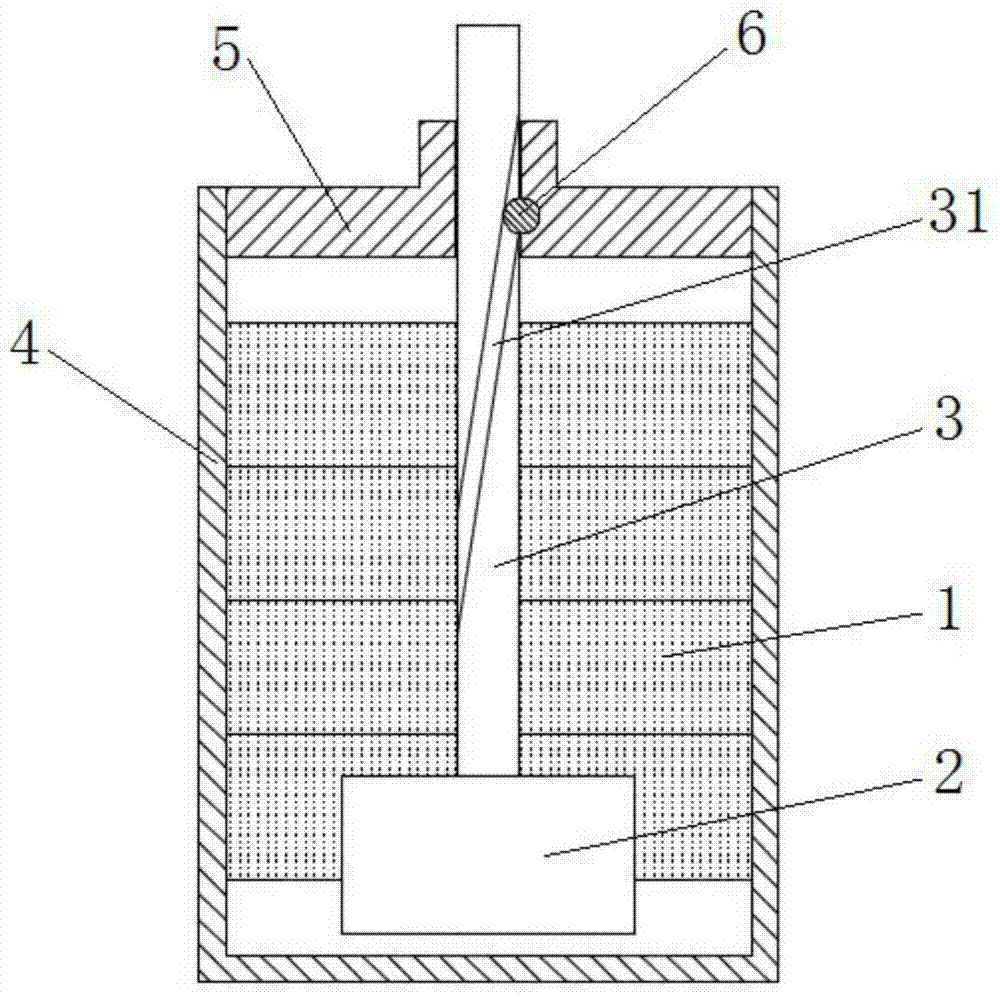

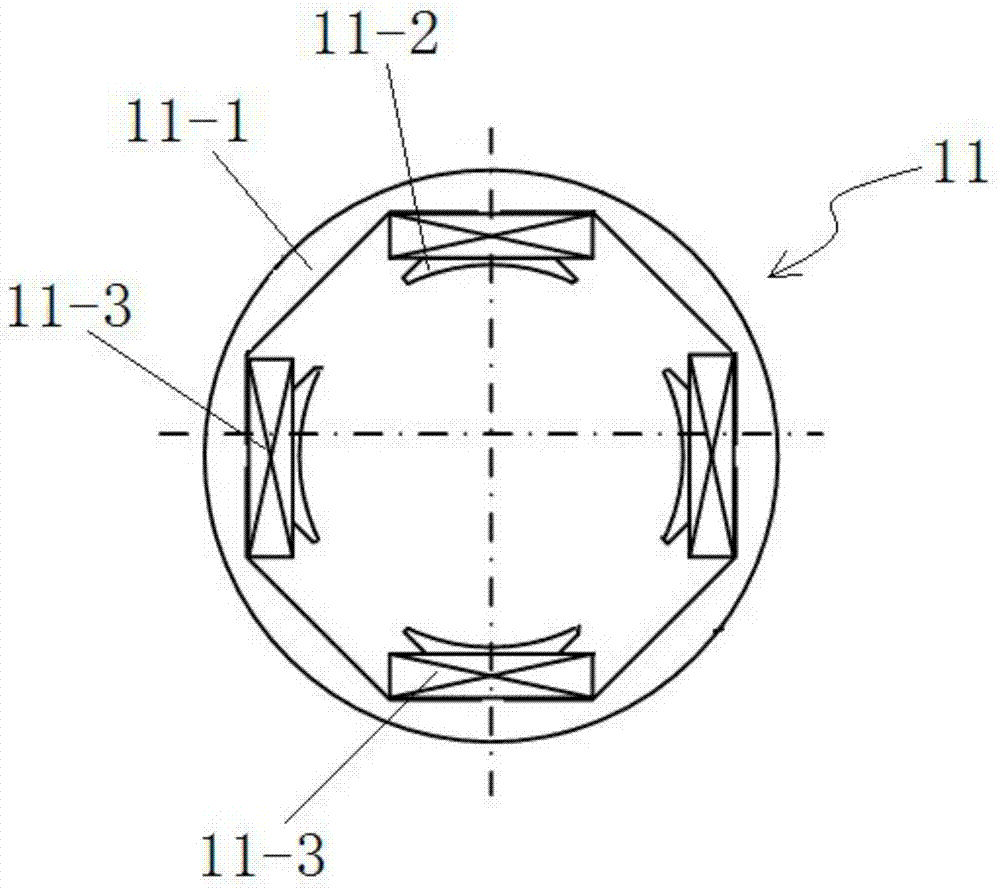

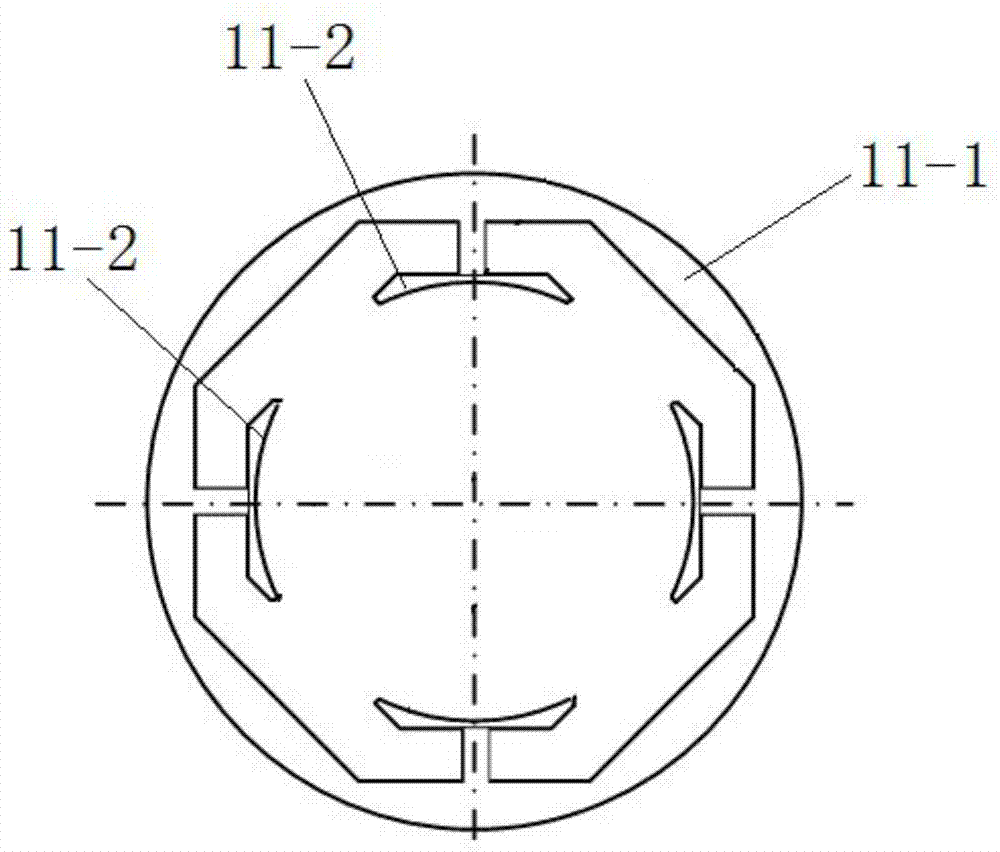

[0040] combine Figure 1 to Figure 11 As shown, taking the static magnetic pole 1 composed of 4 sets of static magnetic pole units 11 as an example, a laminated spiral magnetic thruster in this embodiment includes a casing, a static magnetic pole 1, a moving magnetic pole 2, a propulsion rod 3 and a drive circuit. The static magnetic pole 1 is composed of 4 sets of static magnetic pole units 11 laminations, and the corners of two adjacent static magnetic pole units 11 differ by an acute angle α, and the corner directions of each static magnetic pole unit 11 are all along the same direction. In this embodiment, preferably Therefore, the rotation angles of two adjacent static magnetic pole units 11 differ by an angle α=45°. The static magnetic pole unit 11 comprises a magnetic circuit ring 11-1 and a coil 11-3, and the inside of the magnetic circuit ring 11-1 is equiangularly provided with four magnetic claws 11-2 (such as image 3 shown), the inner profile of the magnetic claw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com