Heavy-duty horizontal filling drive control system and control method

A technology of drive control and control method, applied in the direction of control system, motor control, electrical components, etc., can solve the problems of difficult and smooth continuous advancement, high maintenance cost, complex structure, etc., to reduce design difficulty and cost, and increase system reliability Performance and safety, and the effect of shortening the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention is described in detail below with reference to accompanying drawing and embodiment:

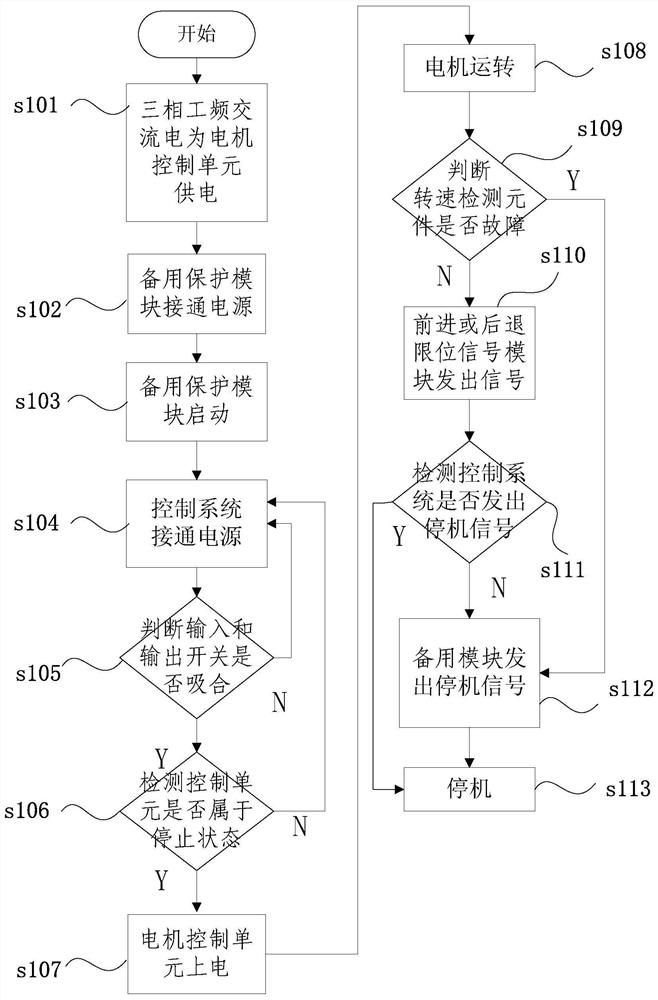

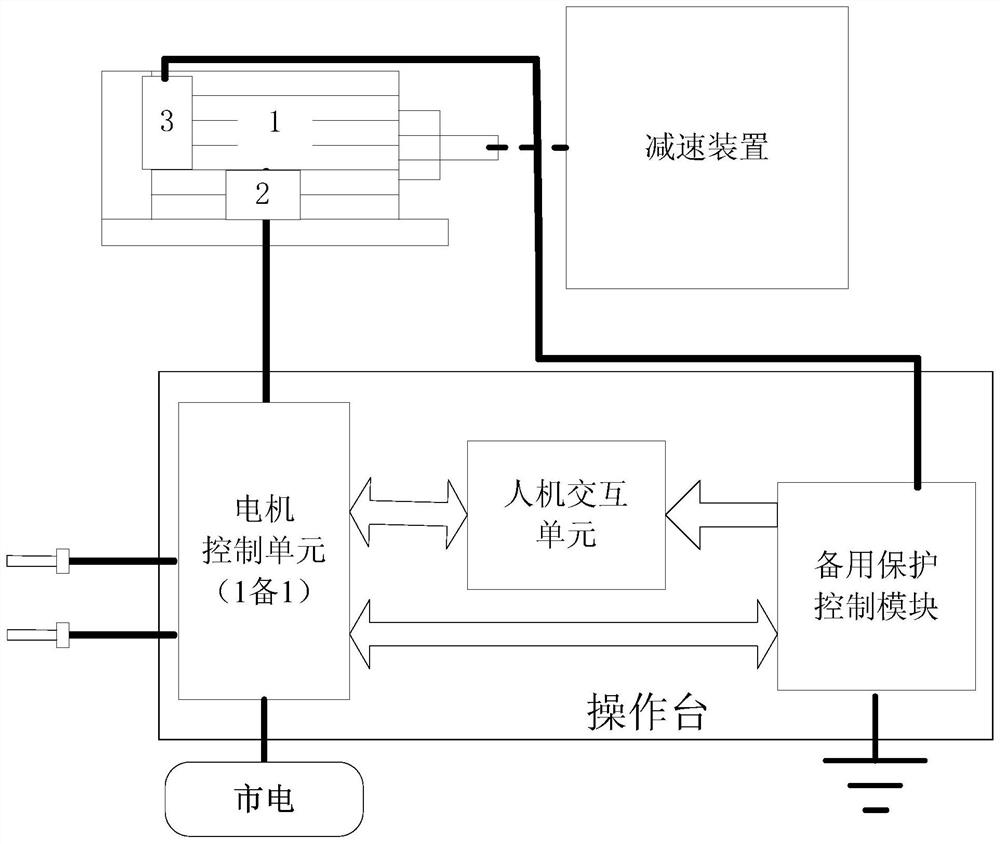

[0040] attached Figure 1-2 It can be seen that a heavy-duty horizontal filling drive control system includes the following steps:

[0041] Step 101, connect the three-phase power frequency alternating current, and the three-phase power frequency alternating current supplies power for the motor and the control unit;

[0042] Step 102, the standby protection control module is powered on;

[0043] Step 103, the standby protection control module starts;

[0044] Step 104, the control system is powered on;

[0045] Step 105, the standby protection control module judges whether the motor control unit power input switch and the output switch are engaged; the motor control unit power input switch and the output switch are engaged to execute step 106, otherwise execute step 104;

[0046] Step 106, the standby protection control module detects whether the control unit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com