Self-centering sleeve head

A self-centering, socket head technology, applied in the directions of wrenches, screwdrivers, manufacturing tools, etc., can solve the problems of inconvenient carrying and high manufacturing cost of the whole set of tools, and achieve the effect of convenient portability and reduced manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings.

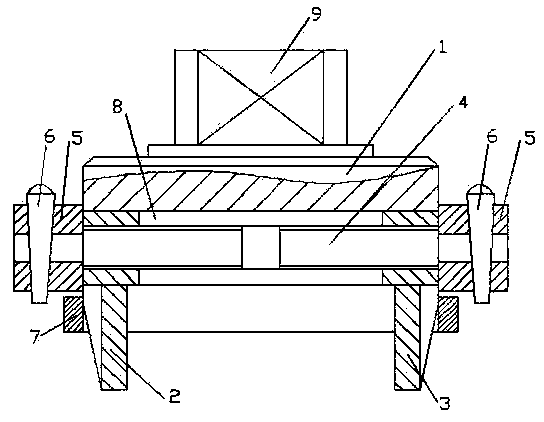

[0011] refer to figure 1 , is a self-centering sleeve head, including a sleeve body 1, a radial chute 8 is arranged on the sleeve body 1, a left clamping block 2 and a right clamping block 3 are arranged in the chute 8, and the left clamping block 2 and the right clamping block 3 can slide left and right along the chute 8, a two-way screw 4 is connected between the left clamping block 2 and the right clamping block 3, and the left clamping block 2 and the right clamping block 3 are threadedly connected with the two-way screw rod 4, Both ends of the two-way screw 4 are respectively provided with fixing sleeves 5 , and the fixing sleeves 5 and the two-way screw 4 are fixedly connected by a limit pin 6 .

[0012] In the present invention, the sleeve body 1 is provided with a fastening nut 7, and the fastening nut 7 is connected to the sleeve body 1 through threads.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com