Amphibious aircraft with wave inhibition groove outer plate

A technology for amphibious aircraft and wave suppression tanks, which is applied to seaplanes, aircraft, motor vehicles, etc. It can solve problems such as serious splashing, deformation and damage of components, and achieve improved splashing performance, improved seakeeping, and increased attendance rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

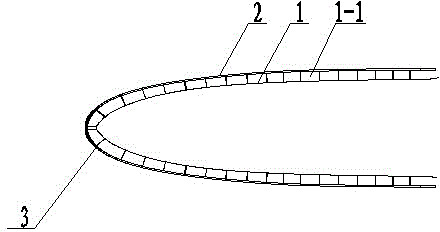

[0012] Such as figure 1 , 2 As shown, the present invention includes an amphibious aircraft body 1, which also has a wave suppression tank outer plate 2 and a set of connecting rods 3, and the wave suppression tank outer plate 2 is installed on the bottom of the amphibious aircraft body 1 through a set of connecting rods 3, and The wave suppression groove 1-1 is formed with the fuselage of the amphibious aircraft body 1.

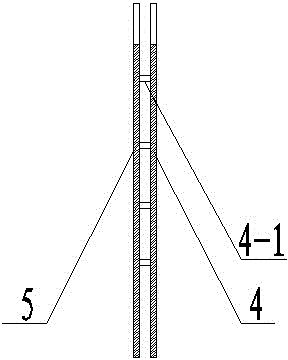

[0013] The outer plate 2 of the anti-wave groove has a group of decompression holes.

[0014] The outer plate 2 of the wave suppression tank includes an outer plate 4 and an inner plate 5, and the outer plate 4 is installed on the inner plate 5 through a set of connecting shafts 4-1.

[0015] The outer plate 4 and the inner plate 5 are metal plates.

[0016] Working principle: The outer plate of the wave suppression groove and the hull of the aircraft form a groove, that is, the wave suppression groove. The splash water generated by the hull enters 1-1 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com