Engine oily structure

A lubricating oil and engine technology, which is applied in the structural field of motorcycle engine gearboxes, can solve the problems of inability to directly wet gears and splashes at the same time, achieve stable and continuous lubrication effects, reduce impedance, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to understand the technical features and practical effects of the present invention in detail, and to implement them according to the contents of the description, the preferred embodiment shown in the accompanying drawings is further described in detail as follows:

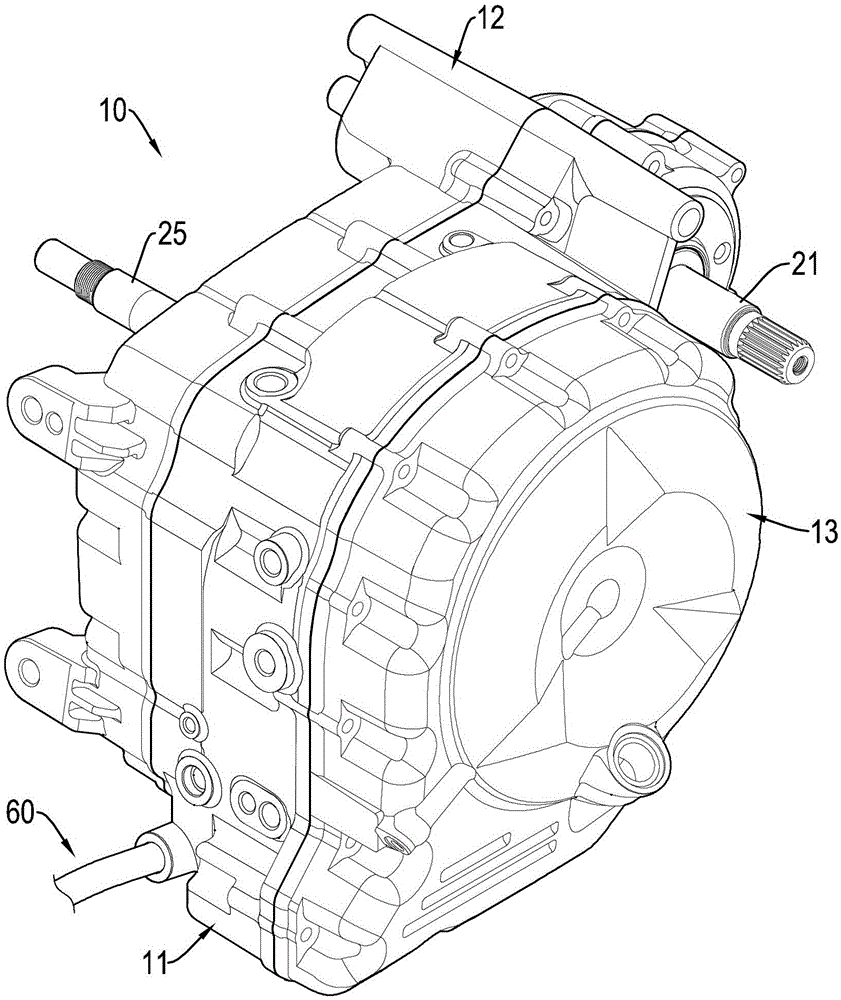

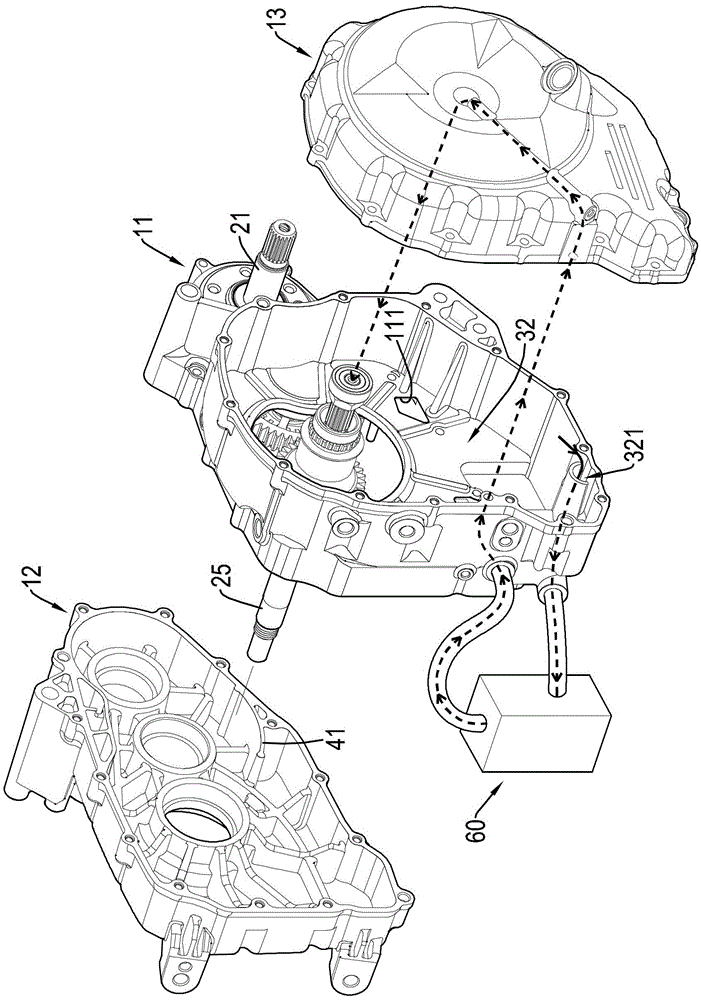

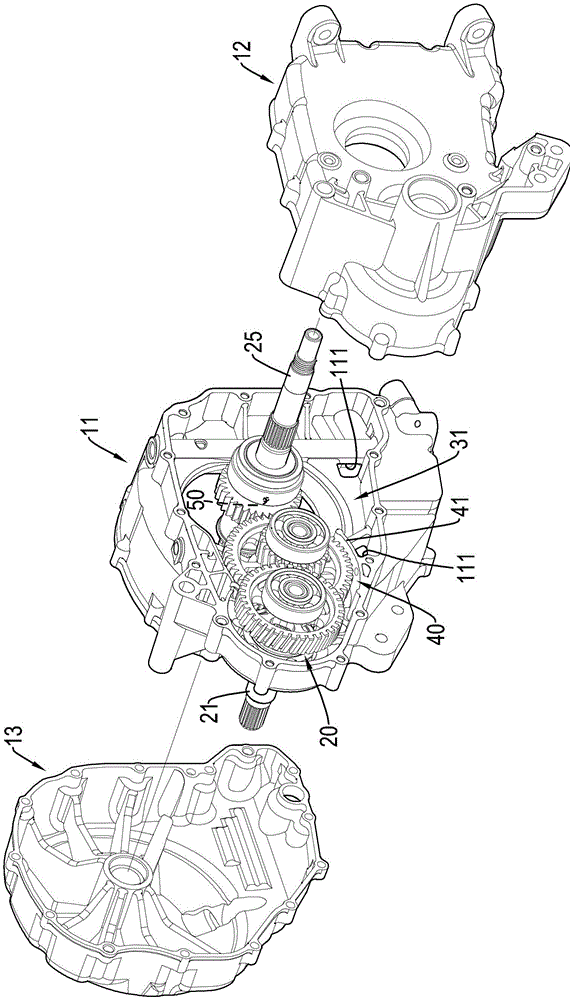

[0038] The preferred embodiment of the oil lubrication structure of a kind of engine provided by the present invention, as Figure 1 to Figure 3 As shown, it includes: a casing 10, a gear set 20, a first oil storage tank 32, a second oil storage tank 40, an oil supply port 50 and an oil pump 60 and other components, wherein:

[0039] Such as figure 2 and image 3 As shown, the box body 10 includes a left casing 11, a right casing 12 and an outer cover 13. The left casing 11 is horizontally provided with two through-shaped oil holes 111. The right casing 12 and the outer The covers 13 are respectively covered and fixed on two opposite sides of the left housing 11 .

[0040] Such as figure 2 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com