Yellow phosphor powder for white light emitting diode, preparation method thereof and white light emitting diode

A technology of light-emitting diodes and yellow phosphors, applied in luminescent materials, chemical instruments and methods, electrical components, etc., can solve problems such as low luminous efficiency, phosphor color reabsorption, and difficulty in ratio control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] Correspondingly, the present invention provides a method for preparing yellow phosphor powder for white light emitting diodes, comprising the following steps:

[0036] mixing the calcium-containing compound, the hydrogen phosphate-containing compound, the cerium-containing compound and activated carbon and then grinding to obtain a mixture;

[0037] Calcining the mixture in a reducing atmosphere to obtain a yellow phosphor powder for white light-emitting diodes with the chemical formula shown in formula (I);

[0038] Ca 4(1-x) O(PO 4 ) 2 :xCe 3+ Formula (I);

[0039] In formula (I), 0.0001≤x≤0.1.

[0040] The present invention uses compounds containing corresponding elements or groups as raw materials, activated carbon as an auxiliary agent, and adopts a solid-phase synthesis method to prepare the yellow fluorescent powder for white light-emitting diodes with the chemical formula shown in formula (I).

[0041] In the embodiment of the present invention, the calciu...

Embodiment 1

[0057] According to the molar ratio of 1:1:0.01, CaCO 3 (analytical pure), CaHPO 4 (analytical pure) and CeO 2 (99.99%) mixed, and 20% (mass fraction) of activated carbon powder was added, fully ground to obtain a mixture.

[0058] Put the mixture into a corundum crucible, then into a large corundum crucible, fill with carbon rods around it, then put it into a high-temperature furnace, and bake it at 1350°C in the presence of carbon monoxide gas. After 10 hours, cool it naturally to Take out and grind at room temperature to obtain a product in the form of yellow powder, which is yellow phosphor powder for white light-emitting diodes.

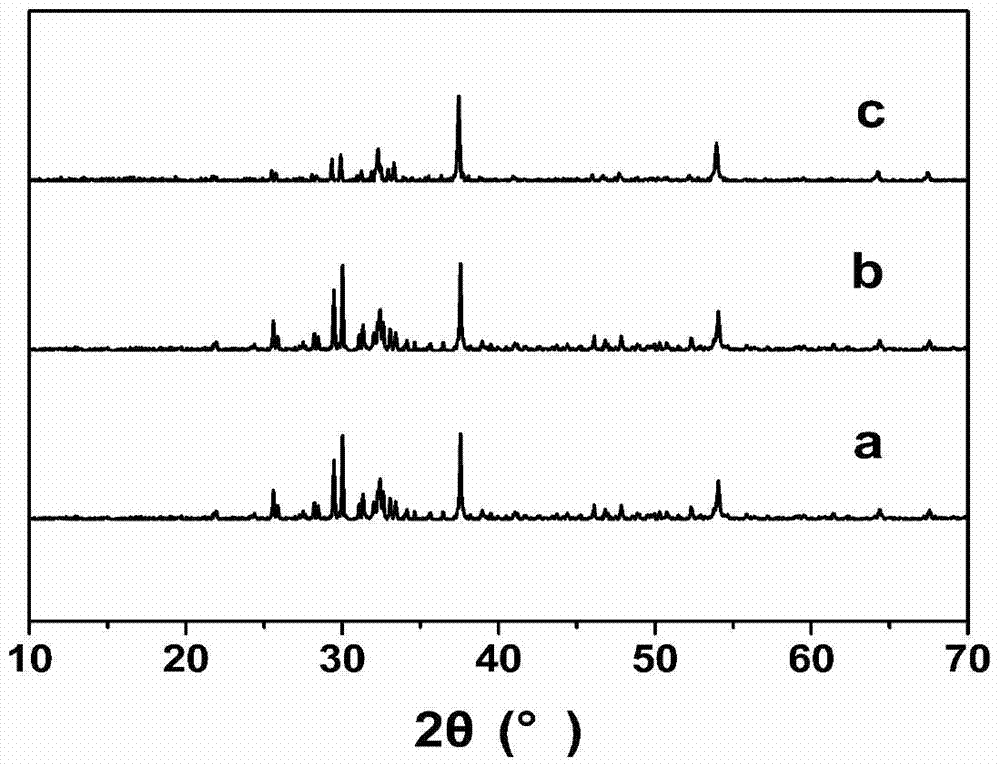

[0059] X-ray diffraction analysis was carried out on the obtained product, the instrument used was German Bruker / D8-FOCUS X-RayDiffractometer, the radiation source was Cu Kα1 (λ=1.5405nm), the scanning range: 2θ=10°~70°, and the scanning speed was 10° / minute. See results figure 1 , figure 1 It is the XRD diffraction spectrum of the produc...

Embodiment 2

[0062] According to the molar ratio of 1:1:0.01, CaCO 3 (analytical pure), CaHPO 4 (analytical pure) and CeO 2 (99.99%) mixed, and 20% (mass fraction) of activated carbon powder was added, fully ground to obtain a mixture.

[0063] Put the mixture into a corundum crucible, then into a large corundum crucible, fill the surrounding with carbon rods, then put it into a high-temperature furnace, and bake it at 1400°C in the presence of carbon monoxide gas. After 7 hours, naturally cool to room temperature , take out and grind to obtain a product in the form of yellow powder, which is yellow phosphor powder for white light-emitting diodes, and the chemical formula is shown in formula (I).

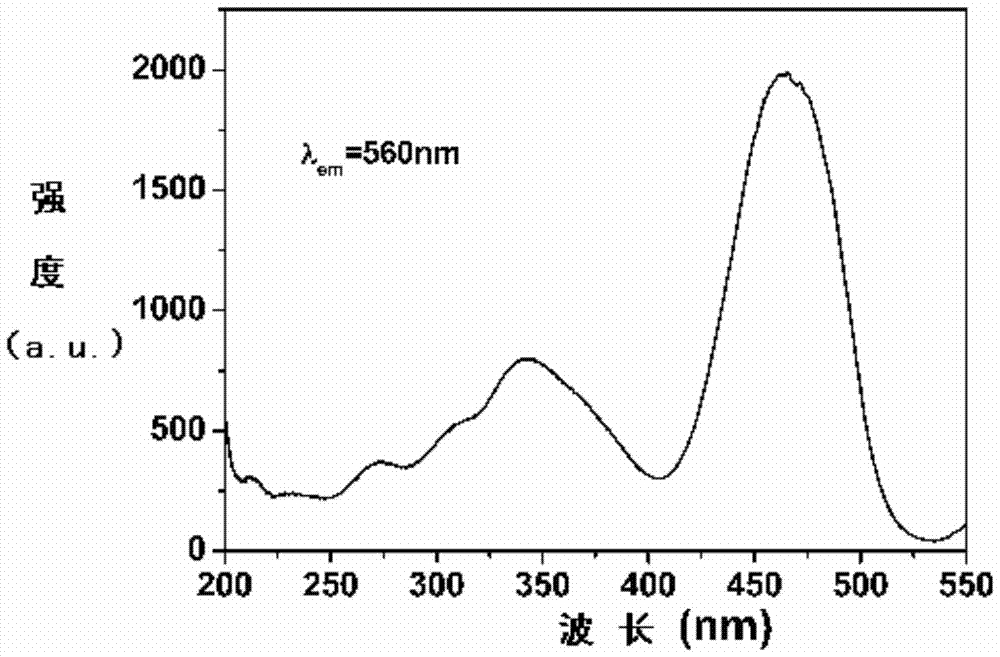

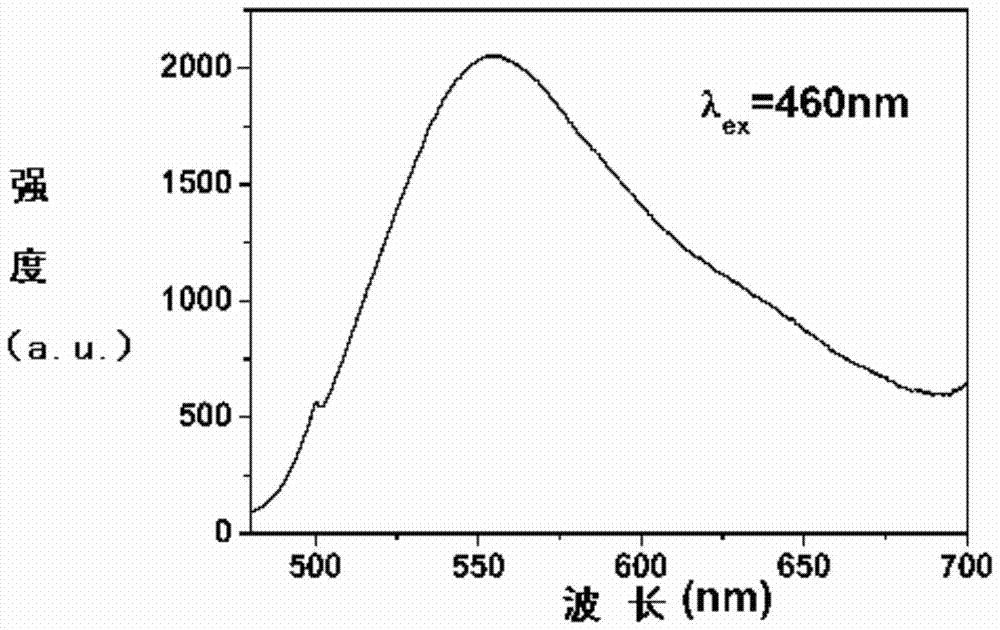

[0064] Gained product is carried out the test of excitation spectrum and emission spectrum, the result sees figure 2 and image 3 . Depend on figure 2 and image 3 It can be known that the yellow phosphor powder for white light-emitting diodes can be effectively excited by near-ultravio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com