Red phosphor for luminescence diode and preparing method thereof

A technology of red phosphor and light-emitting diode, which is applied in the field of preparation of phosphate red phosphor, can solve problems such as failure to realize red light emission, and achieve the effects of stable chemical properties of products, low production costs, and cheap and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Raw material is CaCO 3 (analytical pure), CaHPO 4 (analytical pure), Eu 2 o 3 (99.99%), the molar ratio between them is 0.98: 1: 0.01, the raw material is added into ethanol and fully ground, dried, placed in a corundum crucible, and then put into a high-temperature furnace under a CO atmosphere and roasted at 1350 ° C for 10 Hours, naturally cooled to room temperature to obtain a red fluorescent powder for light-emitting diodes.

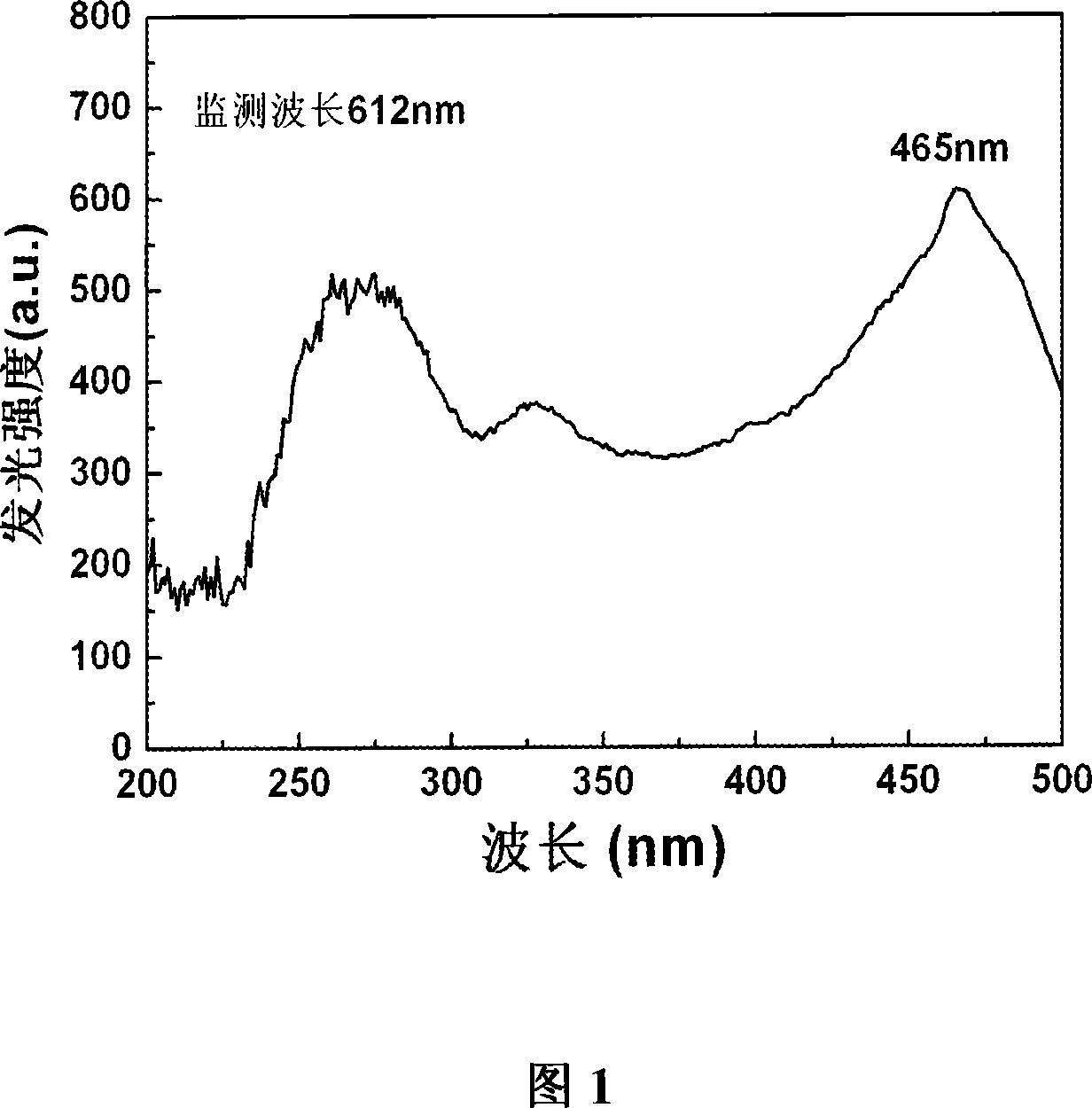

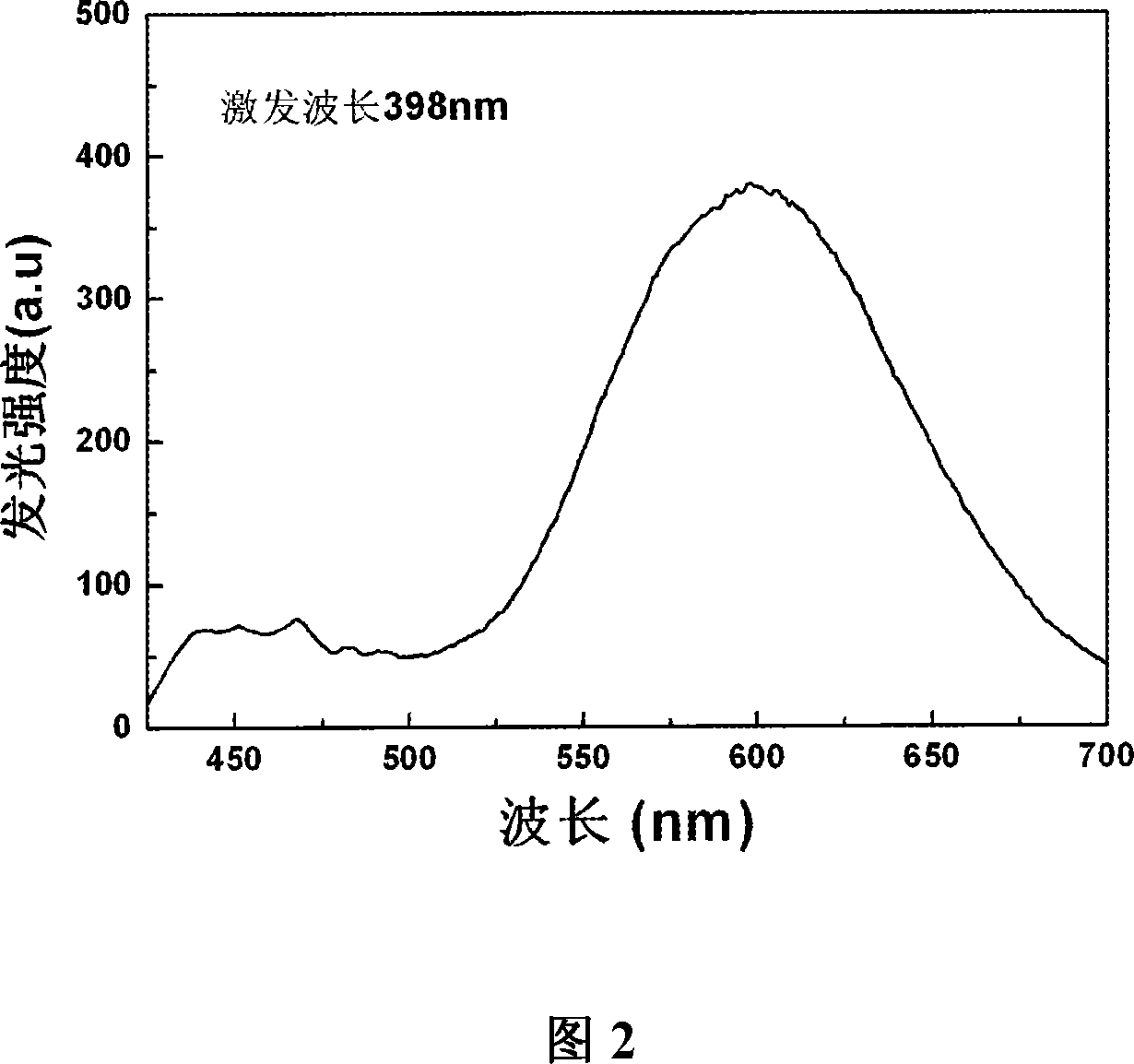

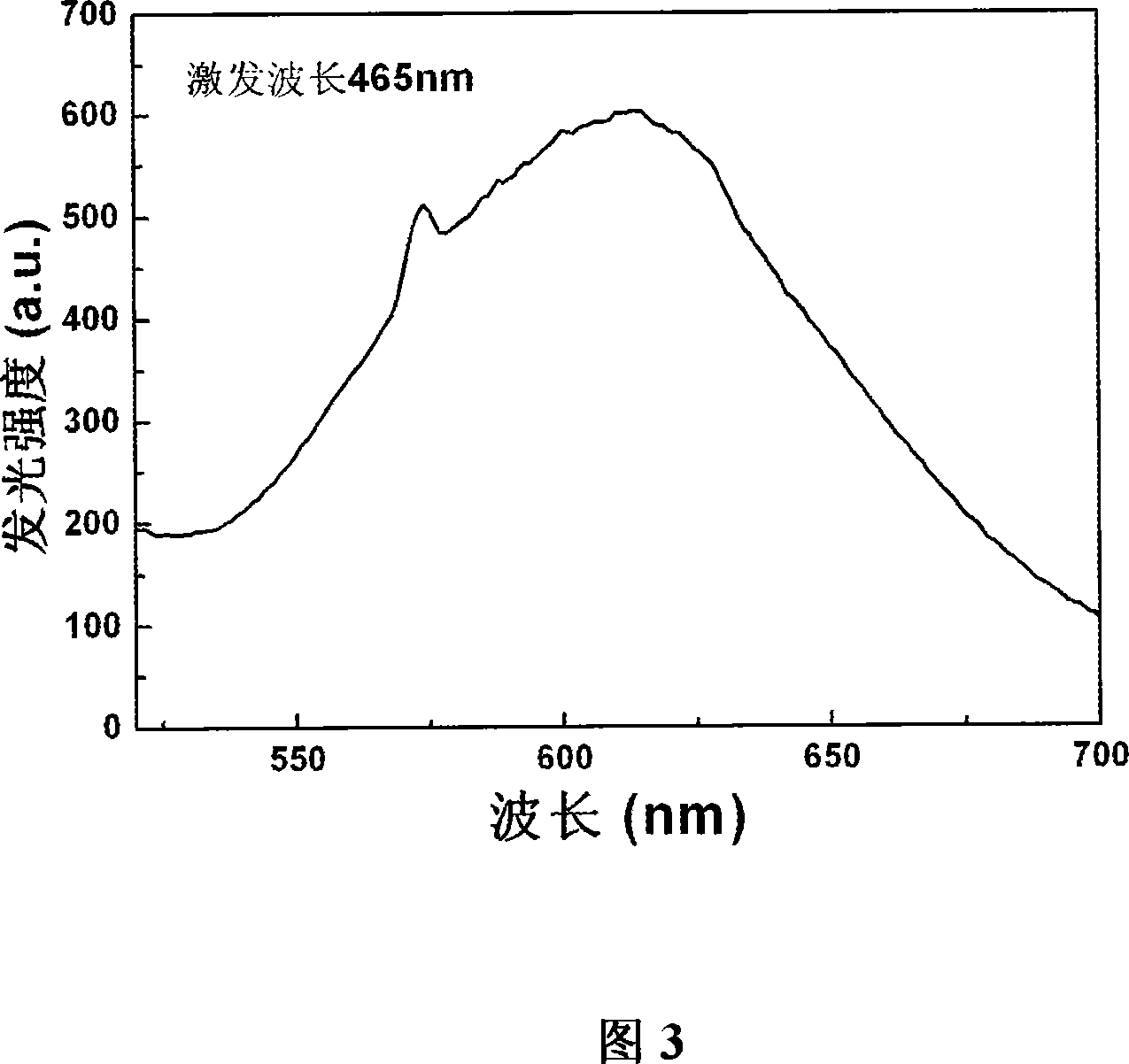

[0016] The obtained red fluorescent powder for light-emitting diodes is yellow-white powder. Its excitation peak is shown in Figure 1; its emission spectrum is broadband emission, as shown in Figure 2 and Figure 3; when excited with 398nm near-ultraviolet light and 465nm blue light, the maximum emission wavelength of the phosphor is located around 600nm and 612nm respectively.

Embodiment 2

[0018] Raw material is CaCO 3 (analytical pure), CaHPO 4 (analytical pure), Eu 2 o 3 (99.99%), the molar ratio between them is 0.98:1:0.01, add ethanol to the raw material and fully grind it evenly, dry it, put it in a corundum crucible, put it into a high-temperature furnace and roast 8 pieces at 1400°C under a CO atmosphere. Hours, naturally cooled to room temperature to obtain a red fluorescent powder for light-emitting diodes.

[0019] The obtained red phosphor powder for light-emitting diodes is slightly yellow powder, and its excitation peak is as shown in Figure 1; its emission spectrum is broadband emission, as shown in Figure 2 and Figure 3; When excited, the maximum emission wavelengths of the phosphors are located around 600nm and 612nm respectively.

Embodiment 3

[0021] Raw material is CaCO 3 (analytical pure), CaHPO 4 (analytical pure), Eu 2 o 3 (99.99%), the molar ratio between them is 0.98:1:0.01, the raw materials are added to ethanol and fully ground evenly, dried, placed in a corundum crucible, put into a high-temperature furnace and roasted at 1450 ° C under a CO atmosphere. Hours, naturally cooled to room temperature to obtain a red fluorescent powder for light-emitting diodes.

[0022] The obtained red phosphor powder for light-emitting diodes is light yellow powder, the color of the sample is darker than that of Example 2, and its excitation peak is as shown in Figure 1; its emission spectrum is broadband emission, as shown in Figure 2 and Figure 3; When excited with 398nm near-ultraviolet light and 465nm blue light, the maximum emission wavelengths of the phosphor are located around 600nm and 612nm respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com