Tamper with handle damping function

A technology of tamping machines and handrails, applied in soil protection, construction, infrastructure engineering, etc., can solve problems such as poor shock absorption effect, and achieve the effect of simple structure, low production cost and reasonable setting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

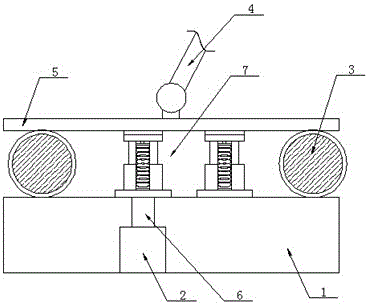

[0016] Below in conjunction with accompanying drawing, the present invention will be further described.

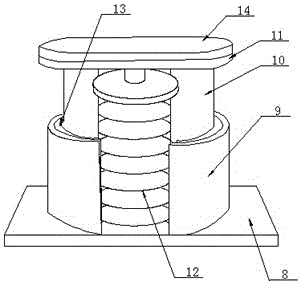

[0017] see as figure 1 —— figure 2 As shown, the specific embodiment adopts the following technical scheme: it includes a ram body 1, a vibration source 2, a rubber ring 3 filled with liquid, a handrail 4, a pressing plate 5, a rigid connector 6, a damping spring shock absorber 7; The inner cavity of the body 1 is provided with a vibration source 2, and the top of the ram body 1 is connected with a handrail 4 through a pressure plate 5, and a rubber ring 3 filled with liquid is arranged between the ram body 1 and the pressure plate 5; the upper end of the vibration source 2 is set There is a rigid connector 6, and the upper end of the rigid connector 6 is provided with a damping spring shock absorber 7; the damping spring shock absorber 7 includes a bottom connecting plate 8, a positioning outer sleeve 9, a positioning inner sleeve 10, an upper connection Plate 11, spri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com