Energy conservation and emission reduction type drying system of gravure workshop

A technology of energy saving, emission reduction and drying system, applied in general parts of printing machinery, printing, printing machines, etc. High efficiency, avoid fire hazards, high efficiency and energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

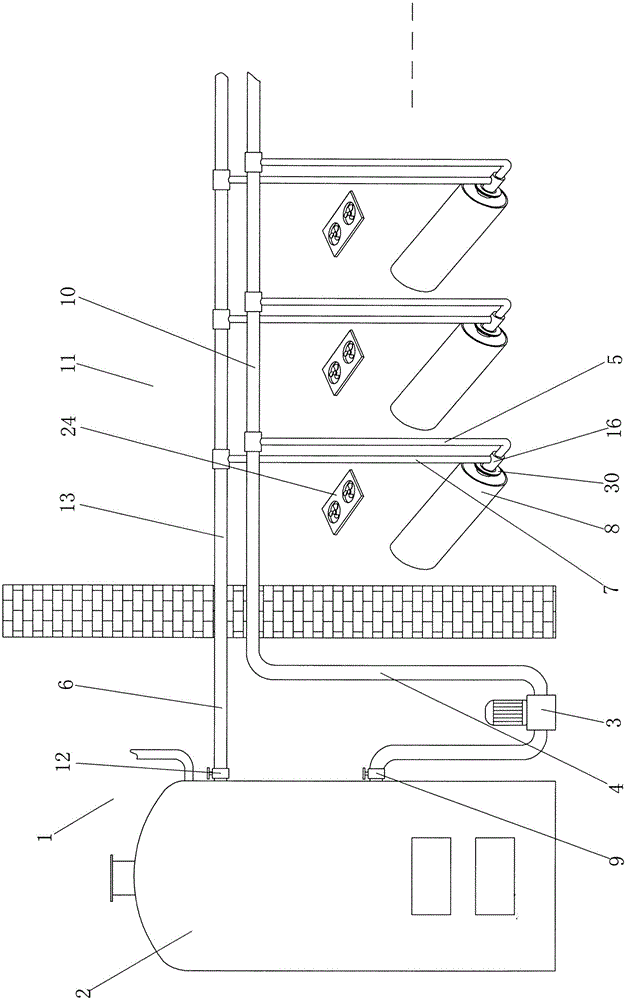

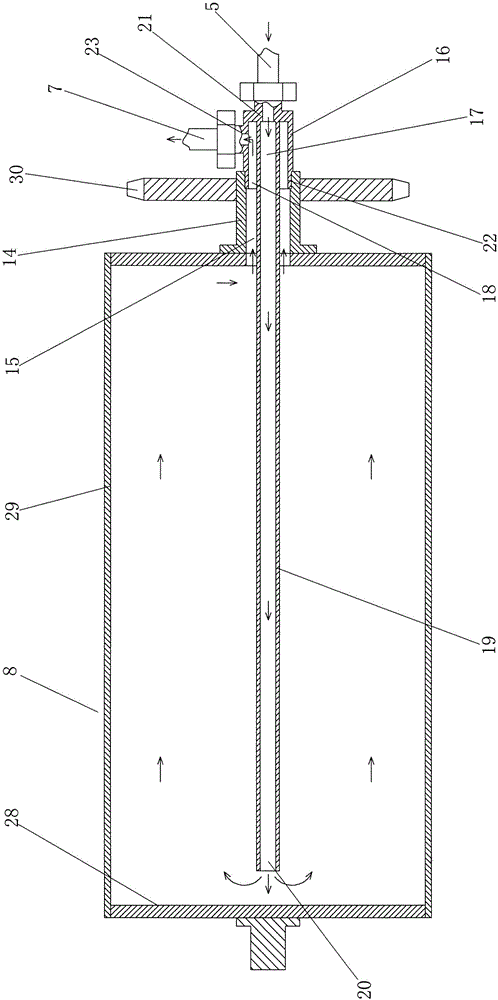

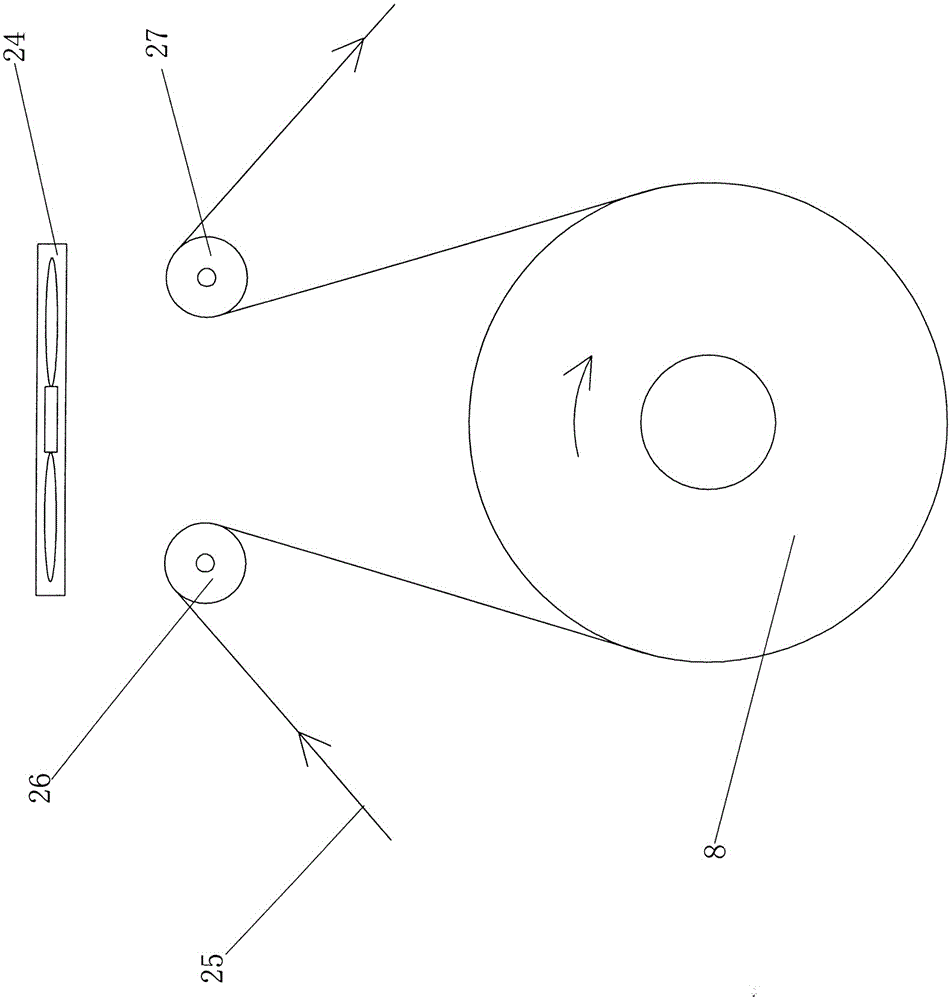

[0025] refer to Figure 1 ~ Figure 3, the energy-saving and emission-reducing drying system of this gravure printing workshop, including a heat source, a heat conveyor and a printing material dryer, the printing material dryer is installed on the post-press station of the gravure printing equipment (not shown), and its characteristic is : the heat source is a steam boiler 2 arranged outside the gravure printing workshop 1, and the heat conveyor includes a blower 3, a steam delivery main pipe 4, some steam delivery sub-pipes 5, etc., a steam return main pipe 6 and a number of steam return sub-pipes 7, etc., The printing material dryer is a plurality of baking cylinders 8 etc. which are respectively rotated and fitted on the gravure printing equipment in the gravure printing workshop and connected with the driver for rotation. The air inlet 9 of the steam delivery main pipe 4 is connected to the The steam outlet of the steam boiler 2, its intermediate connection passes through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com