Graphene superconducting heat pipe and production equipment and technology

A technology for producing equipment and floor heating pipes, which is applied in the field of floor heating pipes, can solve the problems of inability to meet rapid indoor temperature rise, large heat conduction heat loss, and low floor heating efficiency, and achieve the effects of improving heating efficiency, increasing service life, and improving heat dissipation rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention is further illustrated by the following examples.

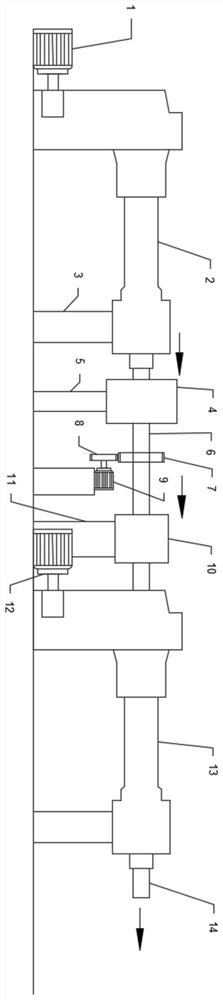

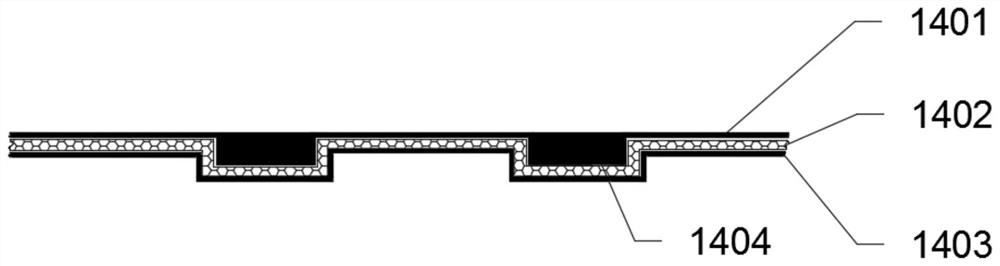

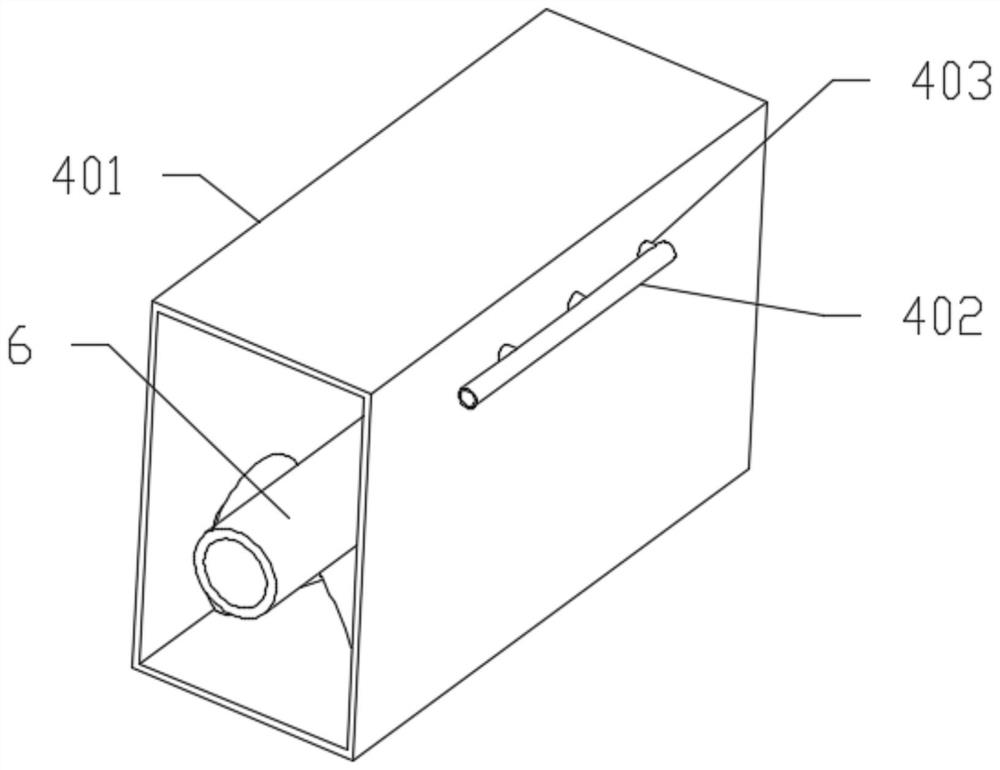

[0041] A graphene superconducting floor heating pipe and its production equipment and process, including a first extruder 2 and a second extruder 13, the first extruder 2 performs an extrusion operation to produce a floor heating pipe semi-finished product 6 The first extruder 2 is connected with the cooling machine 4 to quickly cool the semi-finished floor heating pipe 6, and the cooling machine 4 is connected with the film coating device 7 to cover the semi-finished floor heating pipe 6 with a graphene composite film 1402. The film coating device 7 is composed of a turntable device 8 is driven to rotate to wind the graphene composite film 1402 onto the semi-finished floor heating pipe 6, and the film covering device 7 is followed by a punching device 10, and the punching device 10 is spaced between the inner wall 1403 of the semi-finished floor heating pipe 6 and the graphene composite film 1402....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com