Low-level small shear-type automobile elevator with anti-overturning function and using method of automobile elevator

A technology for lifts and automobiles, which is applied to lifting frames, lifting devices, etc., can solve the problem of not taking into account the pulling up of scissors, and achieve the effect of simple driving mode, convenient expansion and contraction, and prevention of rollover accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

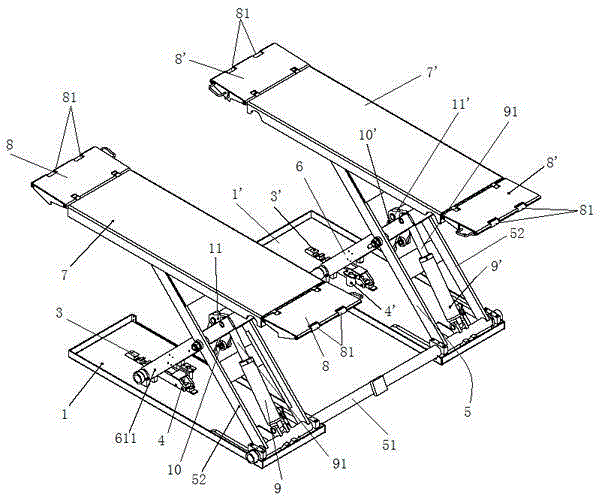

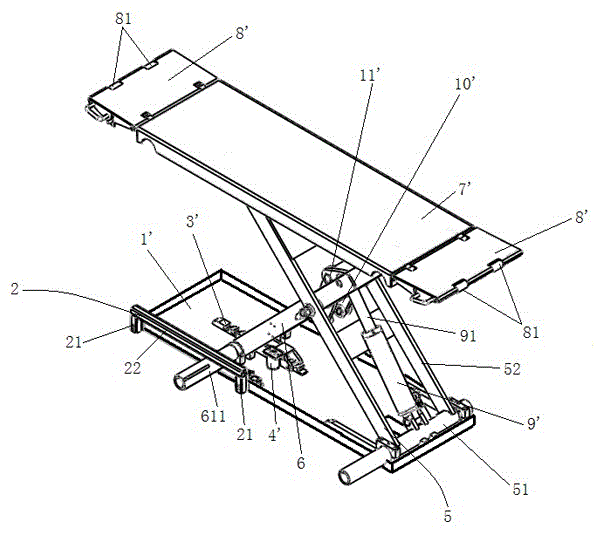

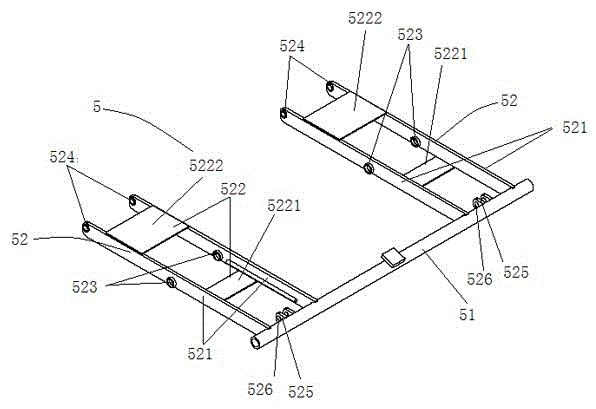

[0022] refer to Figure 1~Figure 4, a low-position small scissor car lift with anti-rollover function according to the present invention, comprising: two bases 1, 1', which are rectangular plates arranged in parallel and at intervals; a limit frame 2 is arranged in it A base 1, 1' is located on one side of the inner length direction, and is formed by two pillars 21 vertically spaced and fixedly arranged on the base 1, 1' and a limit rod 22 detachably connected to the upper ends of the two pillars 21; Safety locks 3, 3', shaped as strips, are respectively arranged in the middle of the upper surface of the two bases 1, 1'; Lock 3,3' are electrically connected to control the opening and closing of safety locks 3,3'; an outer shear arm 5 includes a straight pipe 51 and two support portions 52 that are vertically symmetrically arranged at two ends of the straight pipe 51 side, and the support portion 52 is A frame body, the outer shear arm 5 is detachably connected to the other en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com