Vehicle door hinge and vehicle door installing structure adopting the same

A technology for door hinges and doors, which is applied in the field of auto parts, can solve problems such as appearance defects, corrosion, and inconvenient operation, and achieve the effects of improving visual comfort, reducing operation difficulty, and improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

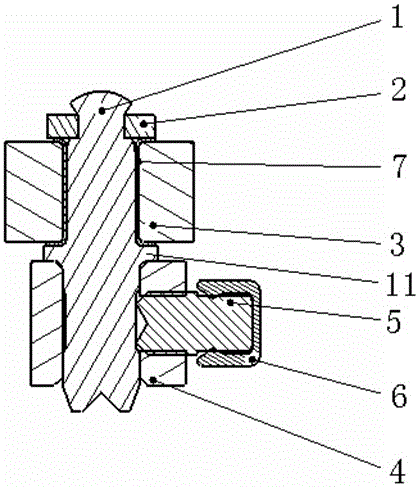

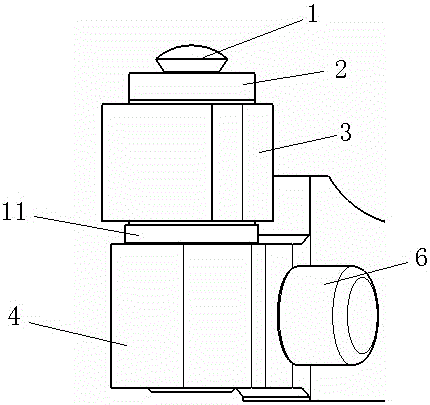

[0019] As shown in the figure, the automobile door hinge structure provided by this embodiment includes: hinge shaft 1, gasket 2, rotating leaf 3, fixed leaf 4, locking pin 5, rotating leaf 3, fixed leaf 4 are all provided with There is an axis hole for the hinge axis 1 to pass through.

[0020] The hinge shaft 1 includes a columnar main body, and the middle part of the main body is provided with a protruding annular flange surface 11; Pages 4 are respectively located on both sides of annular flange surface 11, and said gasket 2 is riveted and mounted on one end of hinge shaft 1 to prevent the rotating page 3 from coming out; annular flange surface 11 can cooperate with gasket 2 to rotate The leaf plate 3 is clamped in the middle to prevent the rotating leaf plate 3 from shaking up and down and falling out downwards.

[0021] The fixed leaf 4 is provided with a through hole perpendicular to the hinge shaft 1, and the locking pin 5 is installed in the through hole. One end of ...

Embodiment 2

[0025] This embodiment provides a car door installation structure using the automobile door hinge described in Embodiment 1, including a door hinge, a car door and a body frame. Different; the rotating leaf 3 in the door hinge is fixedly connected with the door, and the fixed leaf 4 is fixedly connected with the body frame assembly.

[0026] After the door assembly is assembled, when it is installed on the body frame, the longer shaft hinge is installed first, and then the shorter shaft hinge is installed, which can be easily, quickly and conveniently assembled in place. The conventional hinge combination is the same length as the hinge axis 1 of the upper and lower hinge assemblies, so that the worker must make the hinge axis 1 of the hinge assembly rotate up and down when the leaf is turned up and down and align with the 4-axis hole of the fixed leaf on the skeleton. , the 4-axis holes of the upper and lower fixed leaf plates are difficult to be visible to the naked eye at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com