Square cathode wire in electrostatic precipitator

A technology of electrostatic precipitator and cathode line, applied in the direction of electrode structure, electrostatic separation, etc., can solve problems such as unstable connection, low dust collection efficiency, and needle drop of cathode line tube, so as to improve the efficiency of post-sequence dust collection and increase The effect of dust collection area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

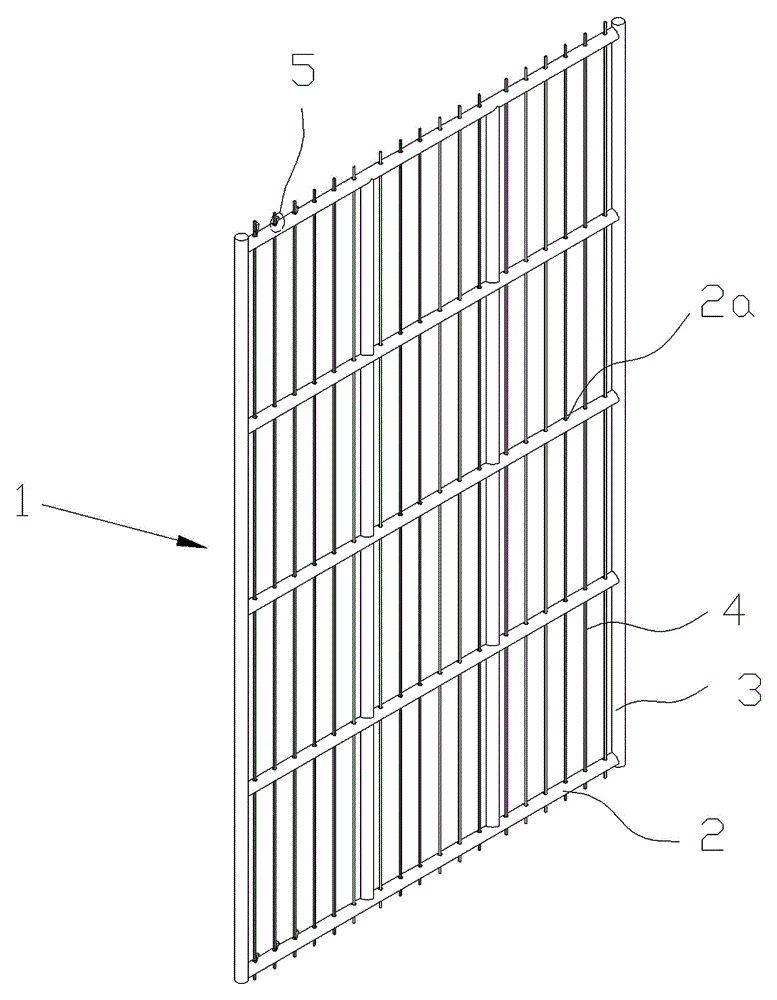

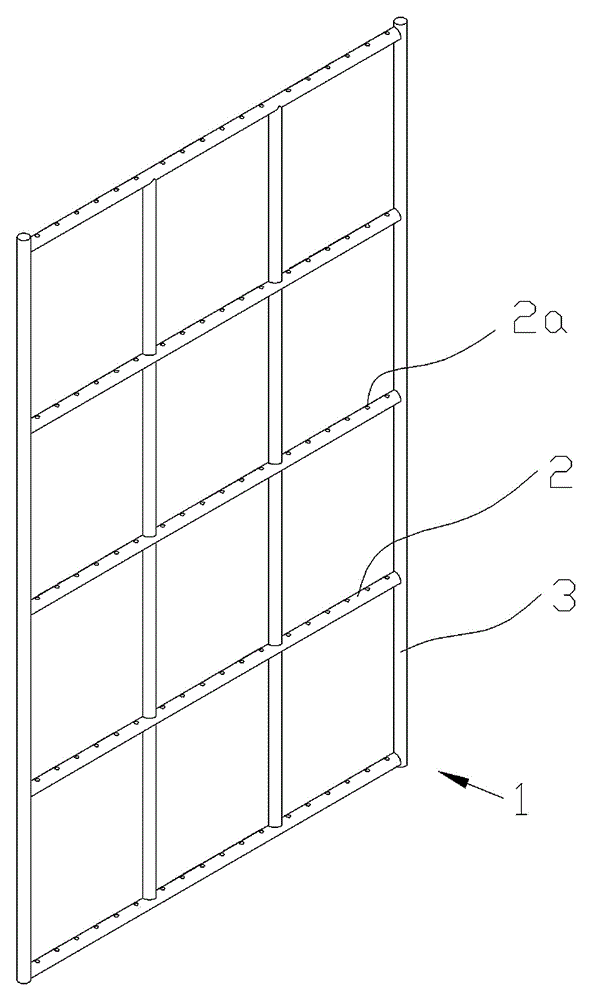

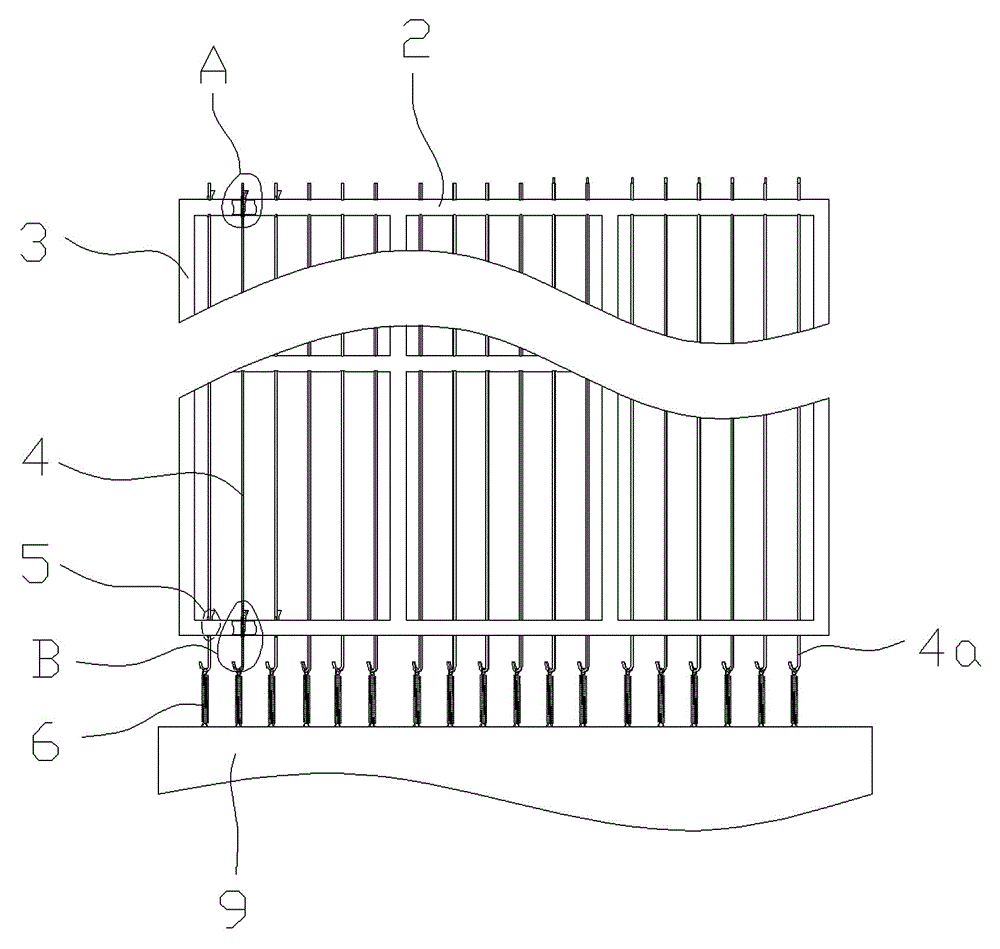

[0019] Such as figure 1 and figure 2 As shown, a square cathode wire in an electrostatic precipitator provided by the present invention includes a square grid cathode frame 1 welded by five transverse frame bars 2 and four longitudinal frame bars 3, and at least one A set of cathode wires 4, characterized in that: the cathode frame 1 has a set of cathode wire installation through holes 2a evenly distributed on each of the horizontal frames 2, and the through holes 2a on the horizontal frames 2 are vertically one-to-one A group of longitudinal through holes are formed through each group of longitudinal through holes 2a, and a cathode wire 4 penetrates and cooperates with each other in each group of longitudinal through holes 2a. The thermal performance is good and the price is cheap. The four right-angled edges of each of the cathode wires 4 are arc radius ≤ 0.1MM, and the four edges and corners of square steel are used to discharge, and the The two ends of the two ends are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com