Pin detaching method for waste chips

A pin and chip technology, which is applied in the field of pin removal of discarded chips, can solve problems such as difficulty in pin extraction, and achieve the effects of increasing hand comfort, reducing production costs, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

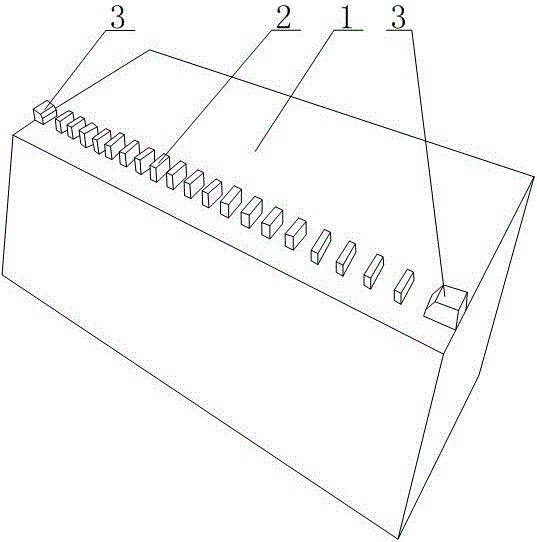

[0019] Such as figure 1 As shown, a method for removing pins of discarded chips in the present invention includes a cuboid base 1 as a whole, and a row of protruding teeth 2 protruding from the upper surface of the base 1 is arranged on the top of the base 1, and the protruding teeth 1 are in the shape of a whole Cuboid, the edges and corners between the upper surface and the side of the convex teeth 2 are removed to form a smooth arc surface, the convex teeth 2 are evenly distributed on a straight line, and the distance from the side of the base 1 is the same, at both ends of a row of convex teeth 2 Anti-fall teeth 3 are respectively provided, and the height of anti-fall teeth 3 is slightly higher than that of convex teeth 2. Meanwhile, the width and length of anti-fall teeth 3 are slightly larger than the width and length of convex teeth 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com