Modifying method of solid epoxy resin

A solid epoxy resin, modification technology, applied in the field of epoxy resin modification, can solve problems such as limiting the application range of solid epoxy resin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

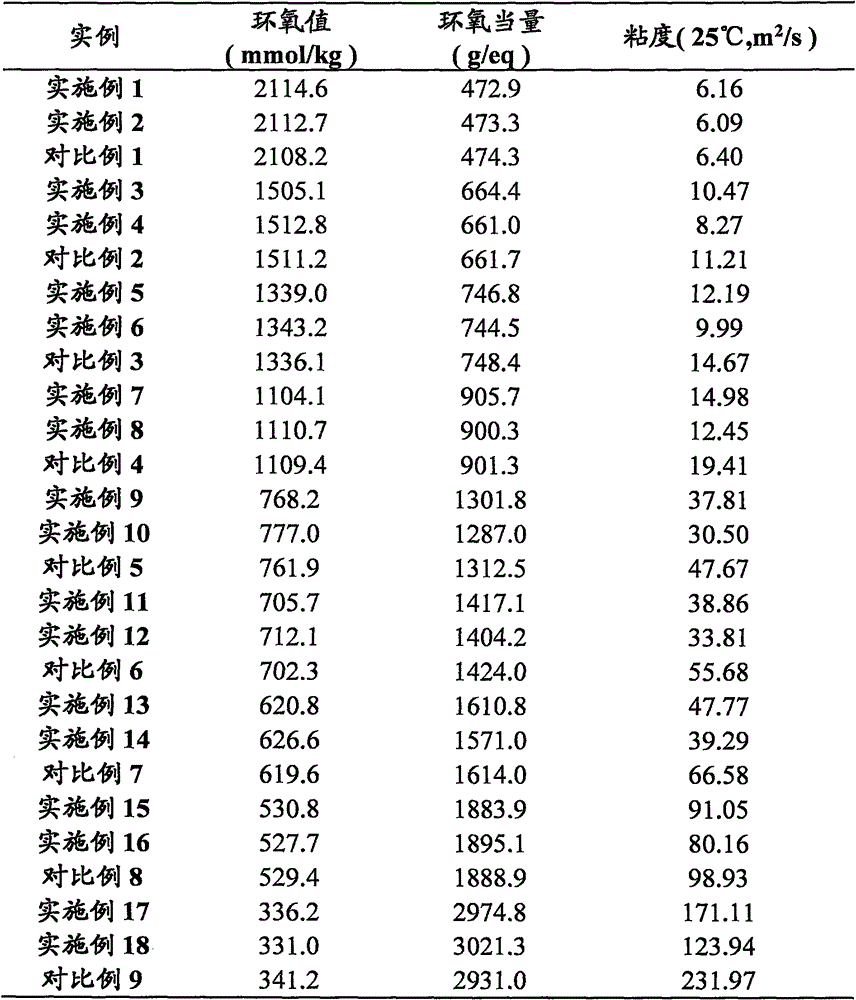

Examples

Embodiment 1

[0046] Set the epoxy resin with the target epoxy value of 2110mmol / kg, the addition of p-tert-butylphenol accounts for 1.5% of the total mass of base resin, bisphenol A, additives and catalysts, and calculate E51, bisphenol A, p-tert-butyl The addition quality of phenylphenol and ethyltriphenylphosphine iodide is 1.1553kg, 0.3222kg, 0.225kg and 450kg.

[0047] Under the condition of nitrogen blanketing, mix E51 and bisphenol A in a reactor by stirring, and heat up to a melting temperature of 120°C to completely melt E51 and bisphenol A to obtain a molten material;

[0048] The obtained molten material is mixed with the additive p-tert-butylphenol and the catalyst ethyltriphenylphosphine iodide, and the temperature is raised to the final reaction temperature of 175°C at a rate of 1°C / min for reaction, and the temperature is controlled at 175±5°C. Cool after reacting for 90min to obtain modified solid epoxy resin.

Embodiment 2

[0050] Adopt the method of embodiment 1 to obtain modified solid epoxy resin, the difference is that in the present embodiment, the addition of p-tert-butylphenol accounts for 3% of the total mass of base resin, bisphenol A, additive and catalyst, and E51, The added masses of bisphenol A, p-tert-butylphenol and ethyltriphenylphosphine iodide were 1.1520kg, 0.3030kg, 0.045kg and 450kg.

Embodiment 3

[0052] Adopt the method of embodiment 1 to obtain modified solid epoxy resin, the difference is, set the epoxy resin of target epoxy value 1510mmol / kg in the present embodiment, calculate E51, bisphenol A, p-tert-butylphenol And the addition mass of ethyl triphenylphosphine iodide is 1.0918kg, 0.3857kg, 0.0225kg and 450kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com