A locking mechanism for installation on a faucet table and a method for installing the locking mechanism

The technology of a locking mechanism and an installation method, which is applied in the bathroom field, can solve the problems of small space under the installation surface of the faucet, difficulty in installing the locking mechanism of the faucet, and inconvenient operation for the installer, so as to improve installation efficiency, wide application range, and compact structure. easy to achieve effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

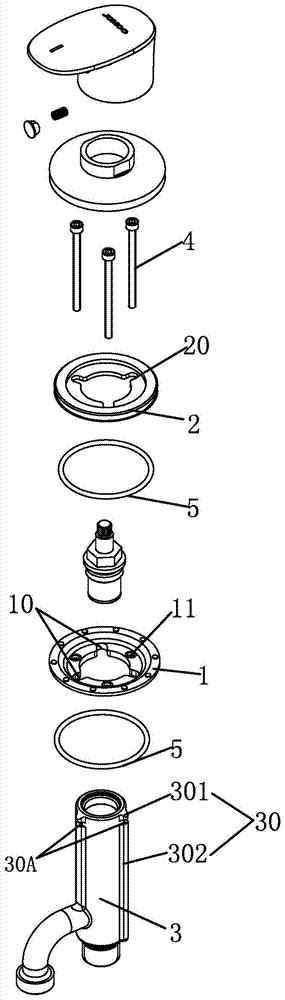

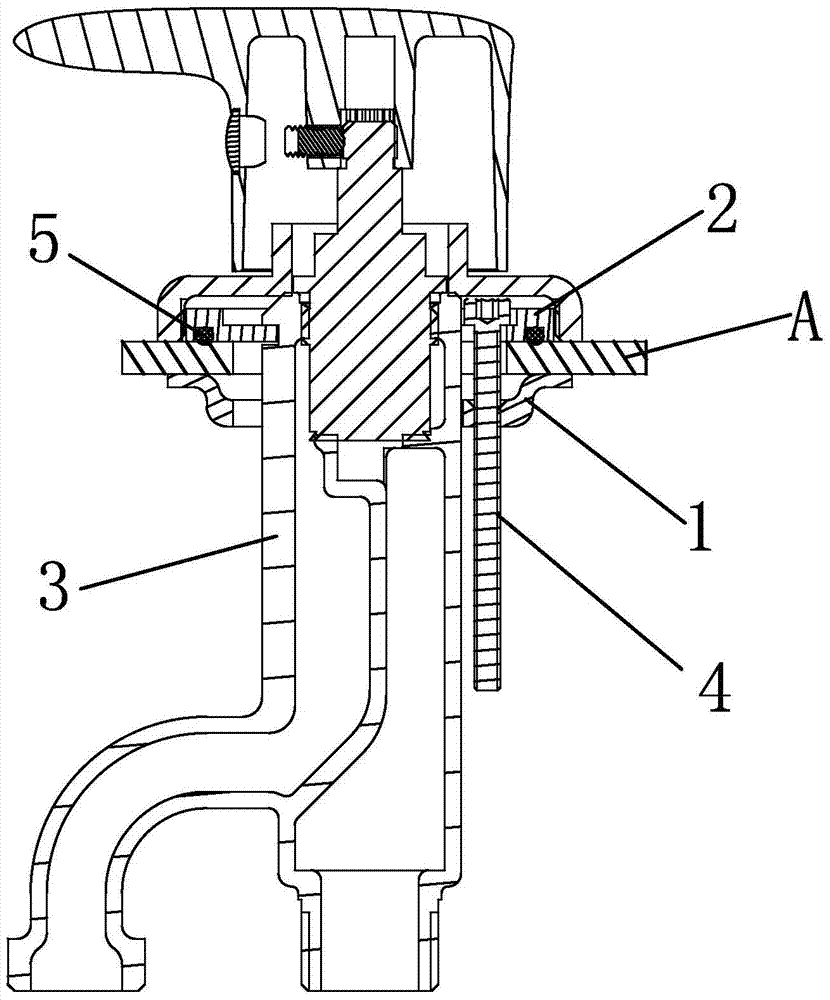

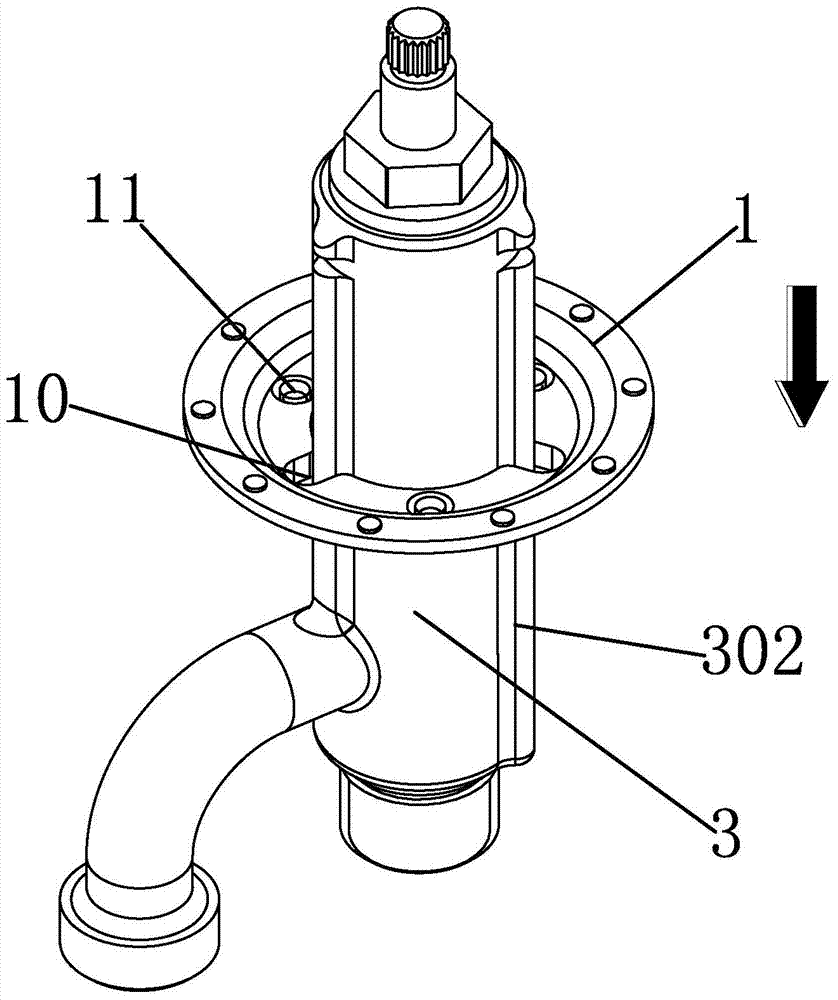

[0038] Specific implementation methods, such as Figure 1 to Figure 7 As shown, a locking mechanism for installation on a faucet platform according to the present invention mainly includes the following components: a faucet body 3, a locking block 1, a snap ring 2 and a connecting piece 4;

[0039] The present invention takes the installation of a bathtub faucet as an example, and the specific installation process is as follows:

[0040] Step 1: Insert the locking block 1 corresponding to the outer peripheral wall of the faucet body 3 and restrict the circumferential rotation of the locking block 1 with the faucet body 3 ; superior;

[0041]Step 2: Insert the clasp 2 into the faucet body 3 above the faucet installation table A, and rotate it at an angle in the circumferential direction to drive the faucet body 3 to hang on the clasp 2; then place the clasp 2 On the faucet installation surface A, the faucet body 3 is hung above the installation table A;

[0042] Step 3: Pass...

Embodiment

[0043] Example, the actual installation process is as follows:

[0044] Step 1: (eg image 3 As shown), the locking block 1 is inserted into the limiting part 302 of the locking rib 30 on the outer peripheral wall of the faucet body 3, and is limited by the locking rib 30 and the second relief part 10 on the locking block 1. bit fit to limit the circumferential rotation of the locking block 1 on the outer periphery of the faucet body 3;

[0045] Step 2: (eg Figure 4 As shown) put the gasket 5 into the faucet body 3, and then install it integrally from bottom to top under the installation table of the bathtub faucet, and make one end of the faucet body 3 penetrate through the installation table of the bathtub faucet; through the setting of the gasket 5, it can effectively prevent Because the installation table A of the bathtub faucet is uneven, the bottom surface of the faucet body 3 is under uneven force, which reduces its service life;

[0046] Step 3: (eg Figure 5 As s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com