Gear transmission device

A technology of gear transmission and gear shaft, which is applied in the field of transmission, can solve the problems of complex assembly of gear trains and high processing requirements, and achieve the effects of reducing mutual influence, reducing processing accuracy requirements, and reducing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

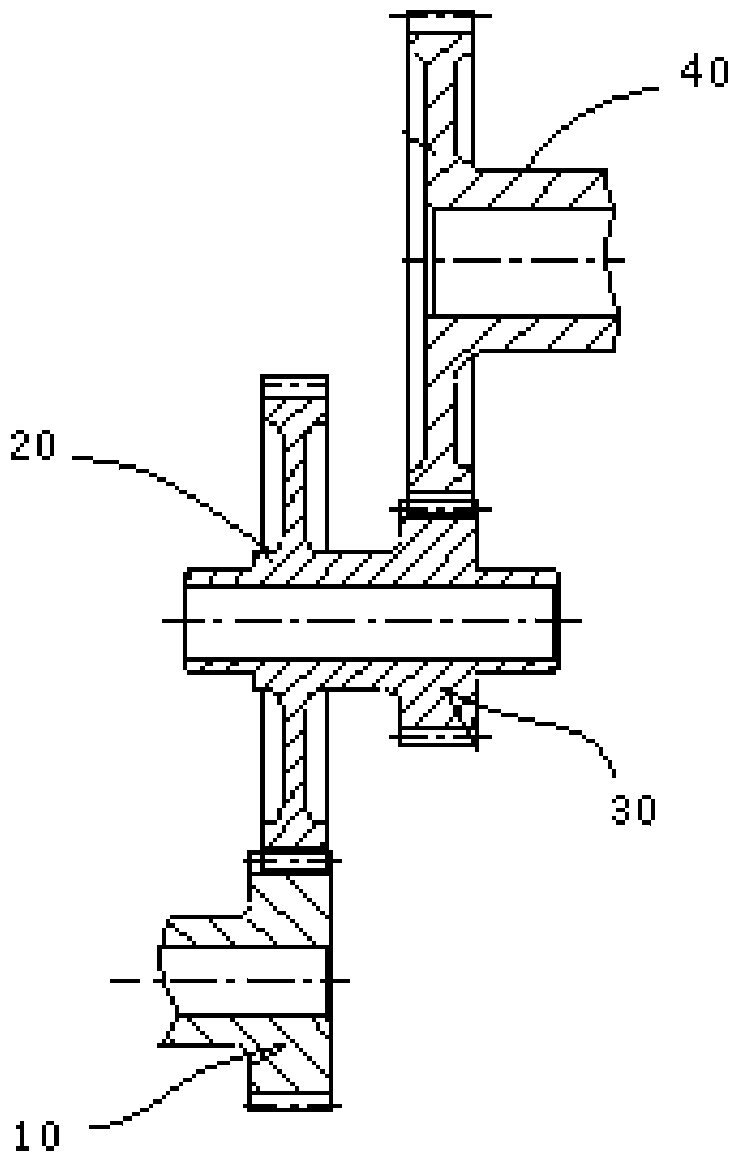

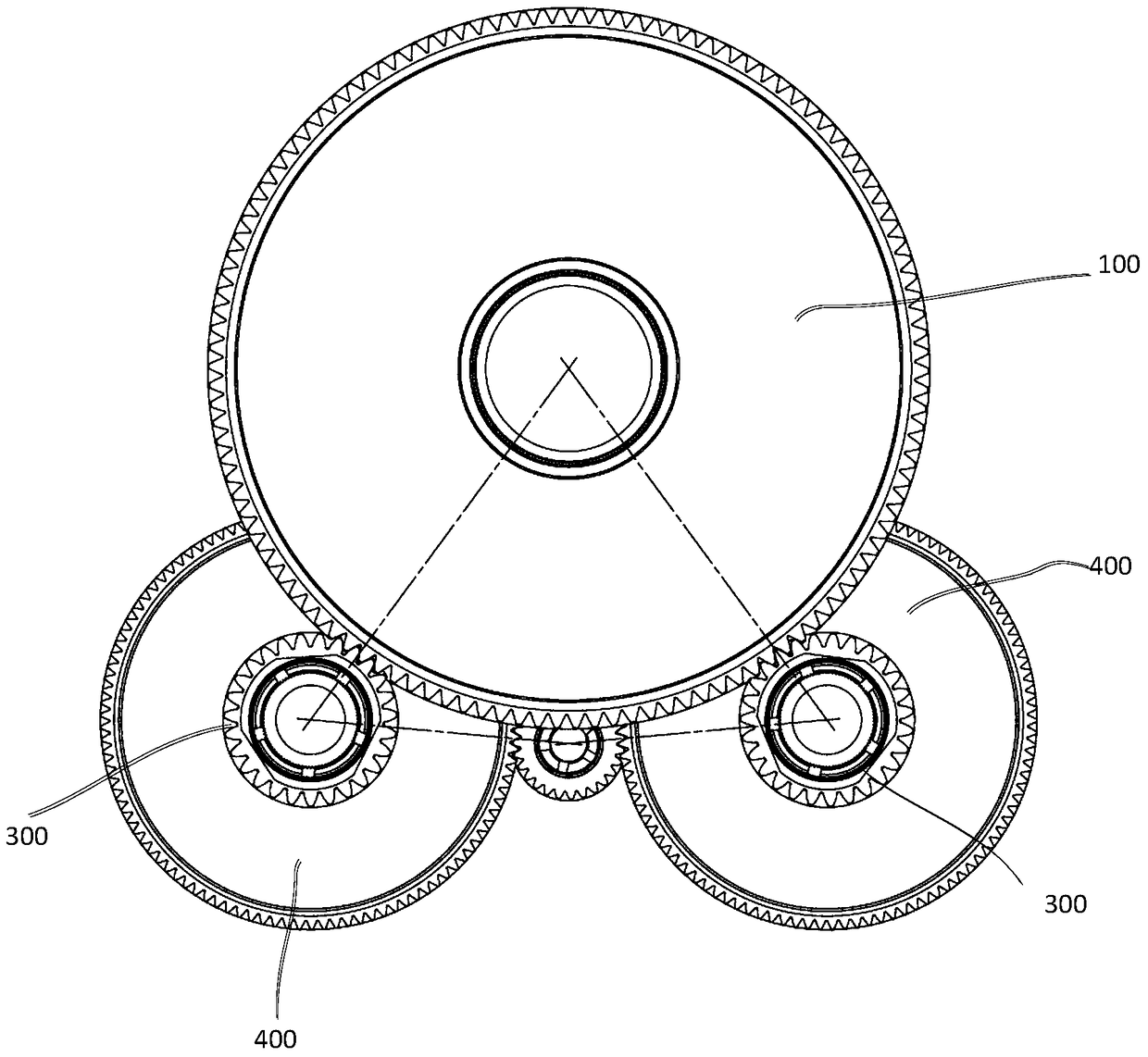

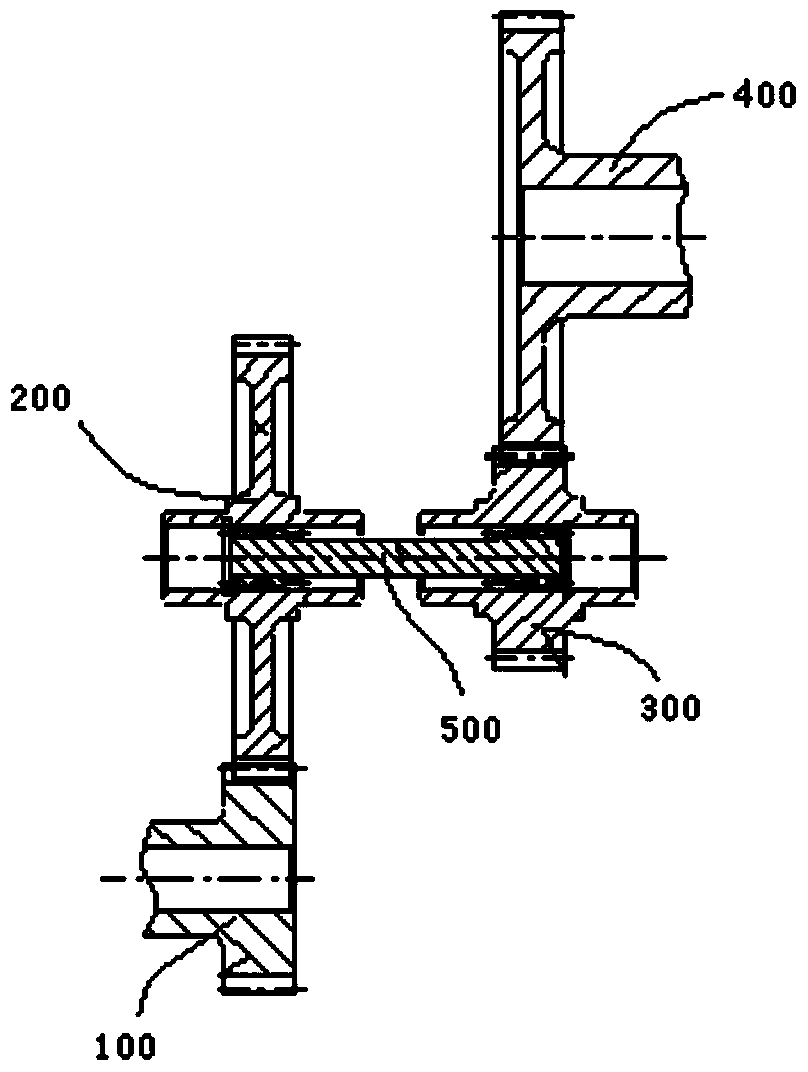

[0027] refer to image 3 with Figure 4 , a preferred embodiment of the present invention provides a gear transmission comprising a primary driving gear 100, a primary driven gear 200, a secondary driving gear 300 and a secondary driven gear 400, a primary driving gear 100 and a secondary driven gear The driving gear 200 meshes, the secondary driving gear 300 and the secondary driven gear 400 mesh, the gear shaft of the primary driven gear 200 and the gear shaft of the secondary driving gear 300 are respectively connected to the two ends of the connecting rod 500, and the primary driven gear The gear shaft of the gear 200 and the connecting rod 500 and / or the gear shaft of the secondary driving gear 300 and the connecting rod 500 are connected by i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com