Axial deviation full-bridge full-interdigital metal strain sheet capable of measuring surface strain axial partial derivative

A metal strain gauge and axial deviation technology, applied in the field of sensors, can solve problems such as inability to detect strain deflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings.

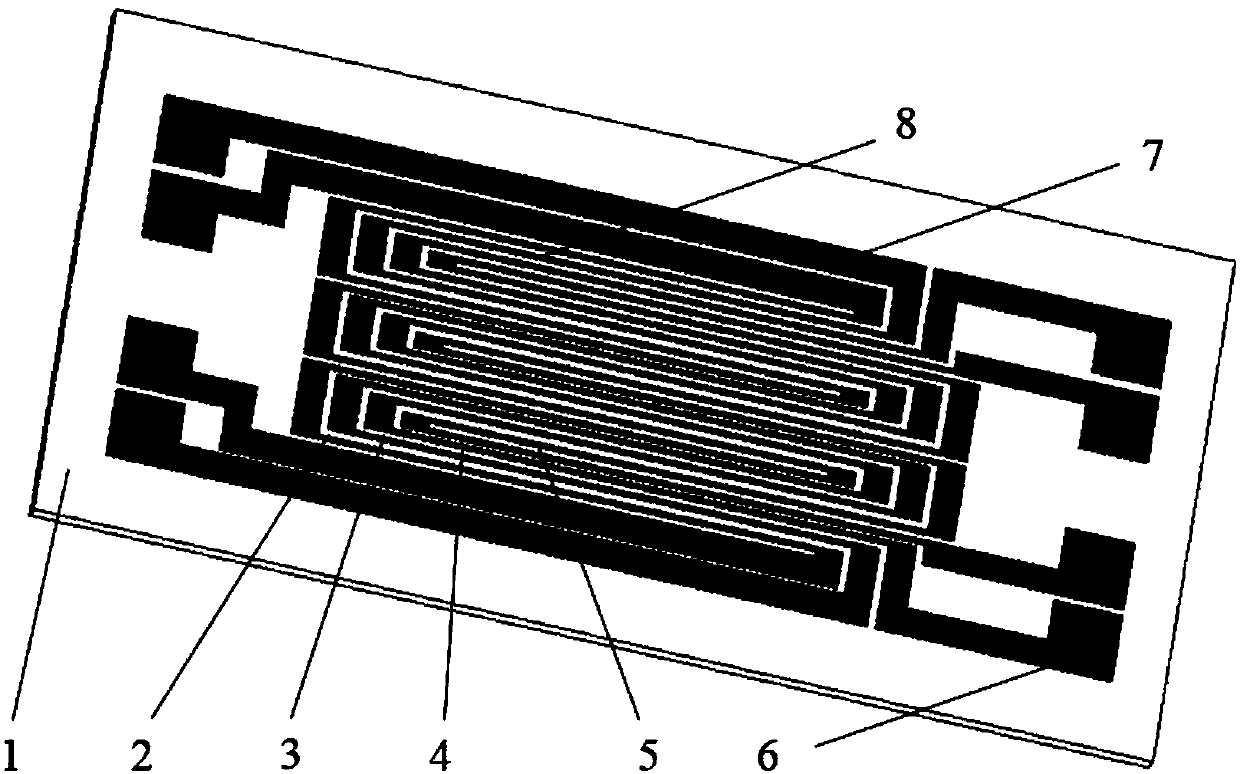

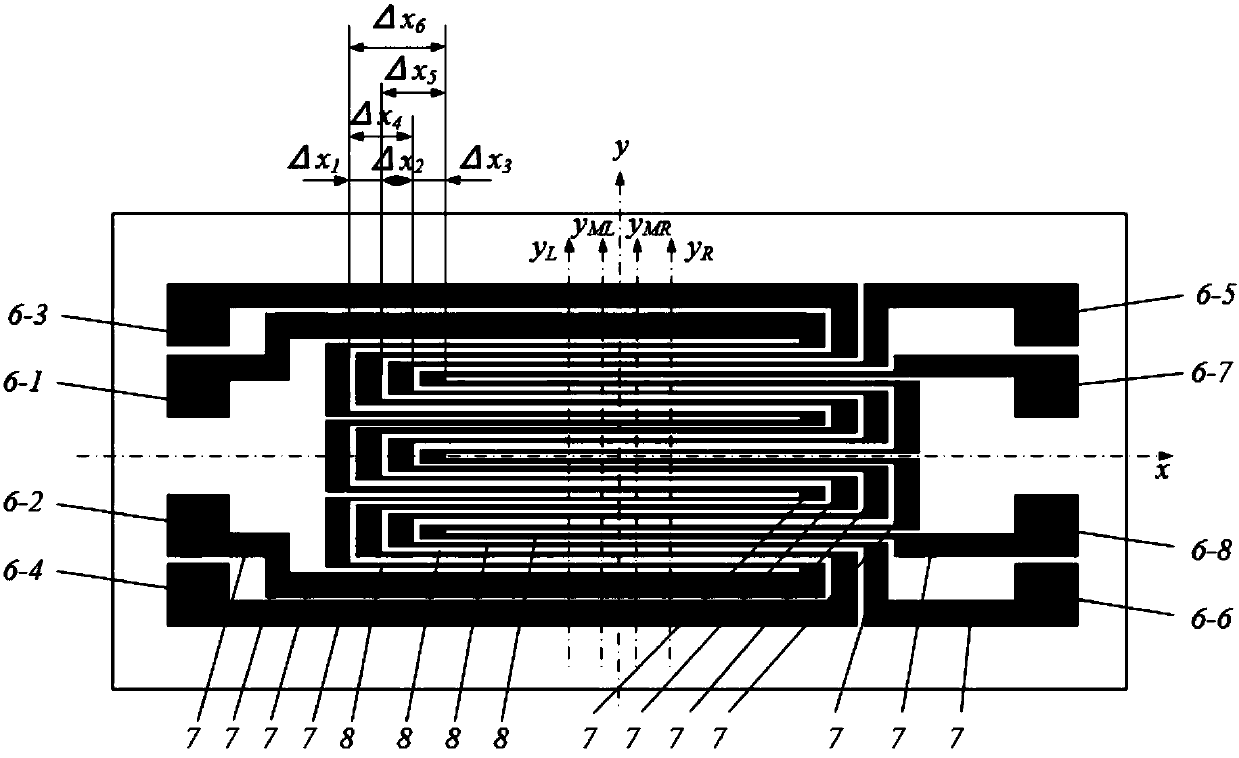

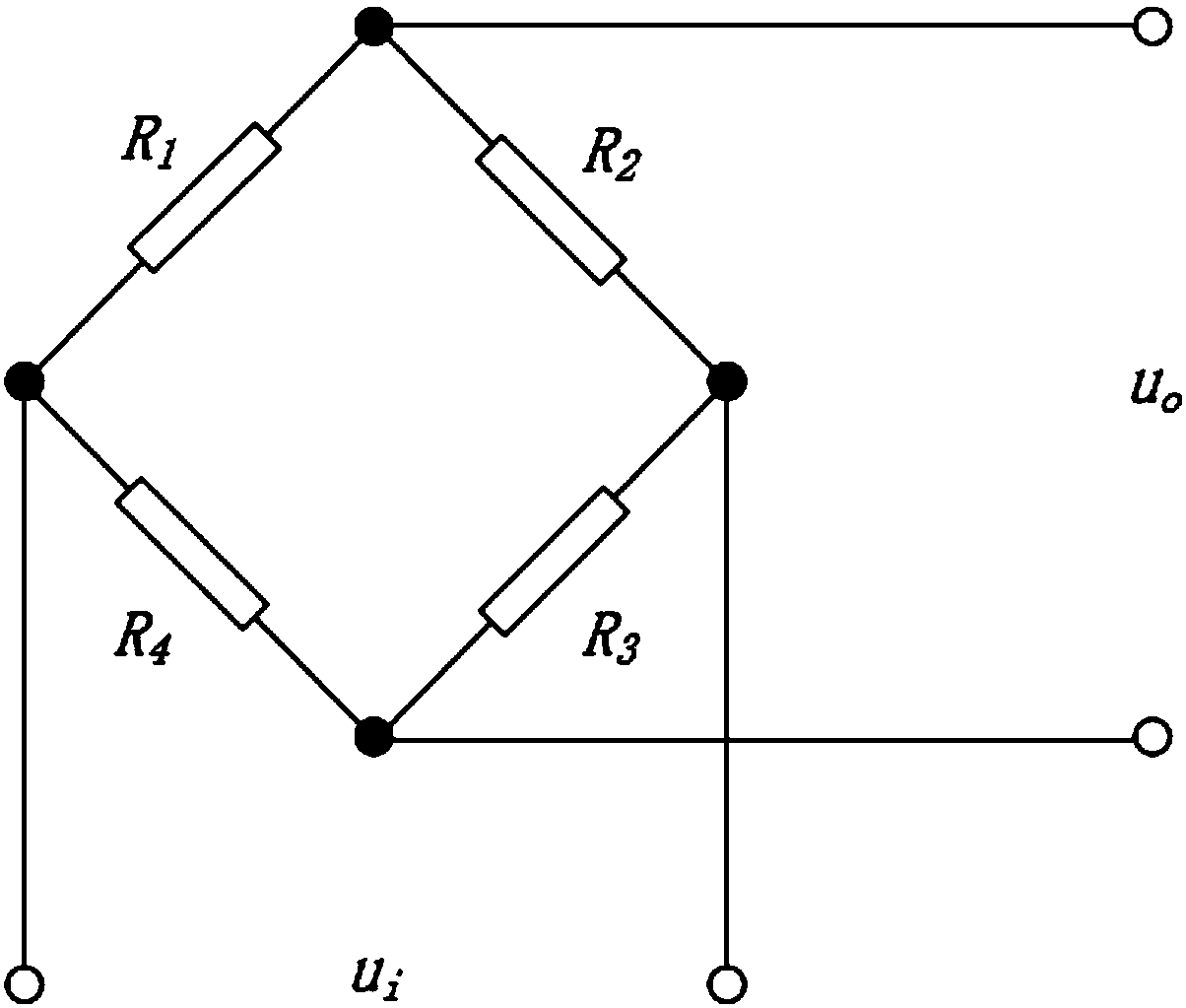

[0032] refer to Figure 1 ~ Figure 3 , a full-bridge full-interdigital metal strain gauge capable of measuring the axial deviation of the axial deflection of the surface strain, including a base, and the metal strain gauge also includes four sensitive grids, and the two ends of each sensitive grid are respectively connected to a a lead wire, the four sensitive grids are fixed on the substrate;

[0033] Each sensitive grid includes a sensitive section and a transition section, the two ends of the sensitive section are transition sections, the sensitive section is in the shape of a long and thin strip, the transition section is in a thick and short shape, and the resistance of the sensitive section is much greater than the The resistance of the transition section, the resistance change value of the sensitive section under the same strain state is much greater than the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com