Motor car axle box temperature detection system and method

A detection system and detection method technology, applied in thermometer testing/calibration, thermometers, measuring devices, etc., can solve problems such as false alarms, inability to install sensors, and inapplicability of pre-inspection, etc., to achieve the effect of strengthening monitoring and reducing false alarms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

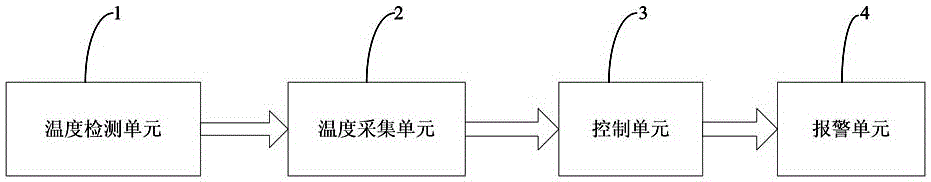

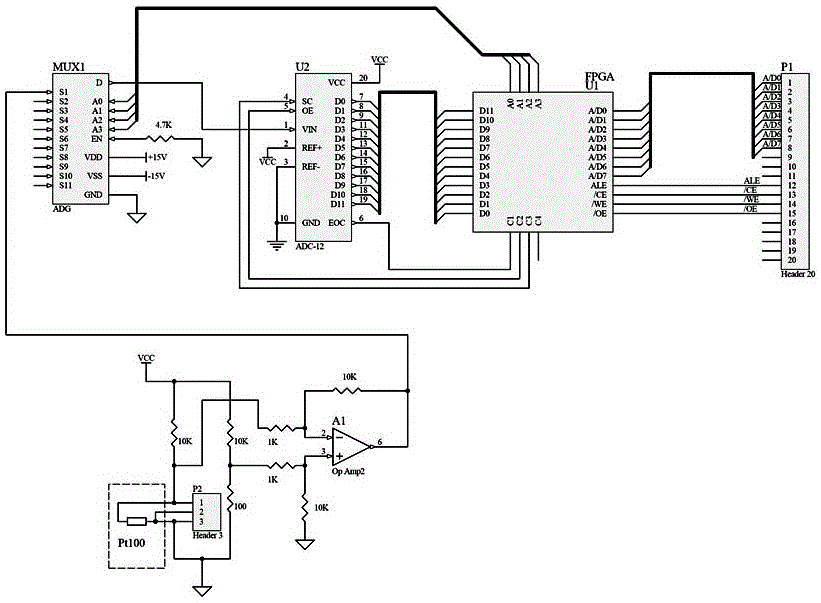

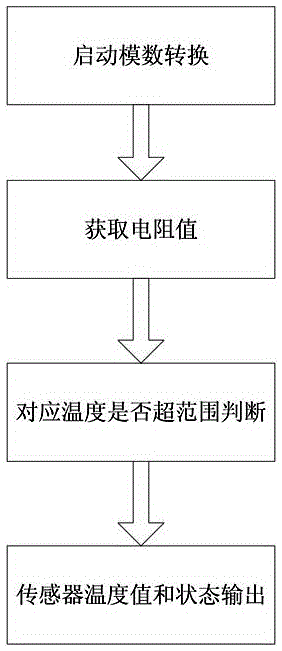

[0027] like Figure 1 to Figure 5 As shown, the motor vehicle axle box temperature detection system in this embodiment includes a temperature detection unit 1, a temperature acquisition unit 2 and a control unit 3 connected in sequence, the temperature detection unit 1 detects the temperature of the motor vehicle axle box and sends a temperature signal to the temperature The acquisition unit 2, the temperature acquisition unit 2 converts the temperature signal into a digital signal and sends it to the control unit 3, and the control unit 3 judges whether the change rate of the digital signal exceeds the preset standard change rate, when the change rate of the digital signal exceeds the preset standard change rate When the speed is high, the control unit 3 judges that the temperature detection unit 1 is abnormal to perform non-stop processing. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com