Pile head fixed end pile-soil dynamic interaction vibration table test device and construction method thereof

A shaking table test and shaking table technology, which is applied in vibration testing, measuring devices, testing of machine/structural components, etc., can solve the problem of not being able to truly simulate the dynamic interaction between support piles and soil, and not being able to fully collect the ends of abutment slabs Problems such as support force and horizontal displacement can be solved to solve the cumbersome effect of test data collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below with reference to the drawings and specific embodiments.

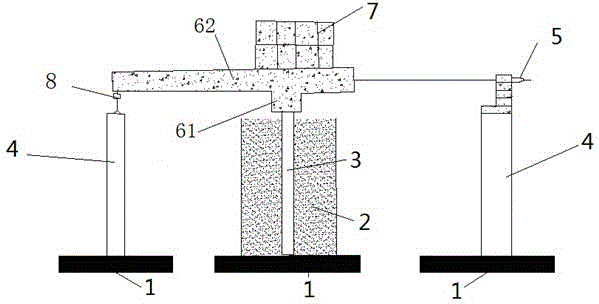

[0020] Such as figure 1 As shown, the sand box 2 is placed on the shaking table top 1, and the corbel 4 is placed on the working table 1 on each side of the sand box 2 to study the seismic performance of the overall structure of the abutment. As shown in the figure, the upper end of the test pile 3 penetrates into the abutment and is consolidated to simulate the real stress performance of the supporting pile of the integral bridge abutment. The abutment 61 and the abutment 62 are integrated. When the abutment 61 is subjected to vibration, the abutment 62 moves horizontally with the abutment 61 as a whole.

[0021] In this embodiment, the test pile 3 is consolidated on the bottom of the sand box 2 and is higher than 1 / 6 of the height of the test pile 3 on the top of the sand box 2.

[0022] The lower surface of the bridge abutment 61 and the slab 62 are f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com