Textile Material Loading Station for Cone Calorimeters

A technology of cone calorimeter and textile material, which is applied in the field of the sample stage carrying the tested textile material sample, can solve the problems of inability to realize the real-time monitoring of the temperature change of the sample and predict the skin burn time, etc., and achieve the extended test detection function. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

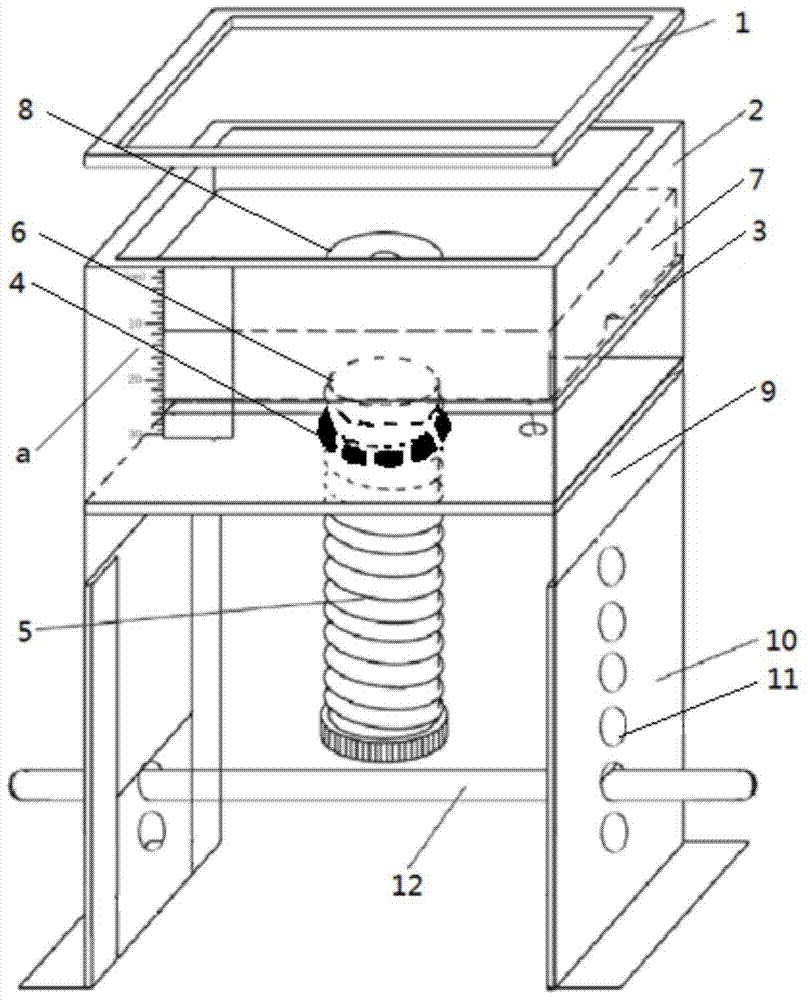

[0015] refer to figure 1 , a textile material sample loading platform for a cone calorimeter, comprising a square box 2 and a magnetic pressure sample frame 1 corresponding to the upper port of the box 2, a vertical To the moving pallet 3, a vertically movable screw mandrel 5 is screwed through the nut 4 fixed at the center of the bottom plate of the box body 2, and the upper end of the screw mandrel 5 is connected with the pallet 3 through a bearing 6. A heat insulating brick 7 with a temperature sensor 8 embedded therein is arranged on the supporting plate 3 .

[0016] The bottom of the square box 2 is provided with a flashboard 9 extending along the side walls, and the square box 2 is inserted on the height adjustment frame 10 through the flashboard 9, and several vertical The distributed positioning holes 11 are used to support and adjust the vertical height of the square box 2 through the clamp bars 12 inserted in the positioning holes 11 .

[0017] The height of the te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com