Novel sample carrying table

A sample loading platform, a new type of technology, applied in the field of new sample loading platform, can solve the problems of real-time monitoring of sample temperature changes and prediction of skin burn time, etc., and achieve the effect of expanding test detection functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

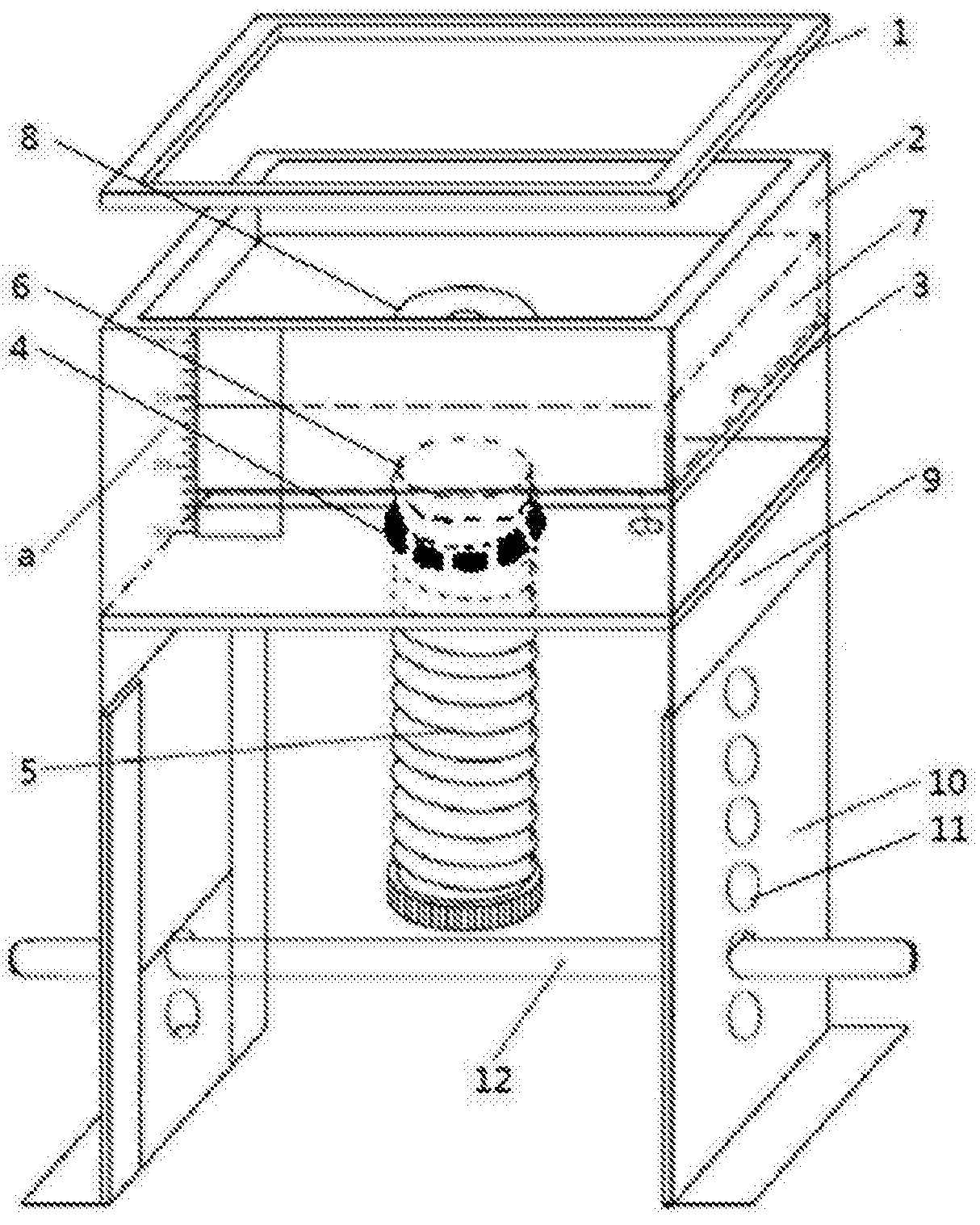

[0014] refer to figure 1 , a new type of sample loading platform, including a square box 2 and a magnetic sample-pressing frame 1 corresponding to the upper port of the box 2, a vertically movable supporting plate 3 is arranged in the box 2, through the fixed The nut 4 located at the center of the bottom plate of the box body 2 is screwed with a vertically movable screw rod 5, the upper end of the screw rod 5 is connected with the supporting plate 3 through a bearing 6, and a built-in screw rod is arranged on the supporting plate 3. The insulation brick 7 that is provided with temperature sensor 8.

[0015] The bottom of the square box 2 is provided with a flashboard 9 extending along the side walls, through which the square box 2 is inserted on the height adjustment frame 10, and several vertical The distributed positioning holes 11 are used to support and adjust the vertical height of the square box 2 through the clamp bars 12 inserted in the positioning holes 11 .

[0016...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com