Diaphragm for winding double-layer coil

A dual-coil, die-cut technology, applied in the direction of coil manufacturing, can solve the problem of inability to meet high-power power supplies, and achieve the effects of easy popularization and application, reduced production costs, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

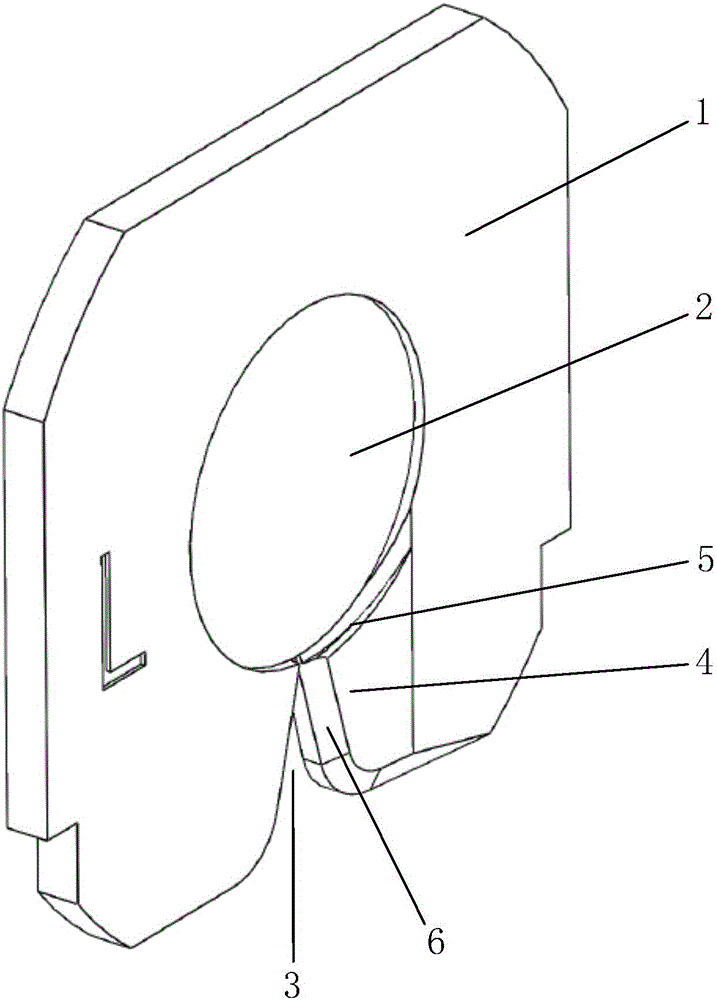

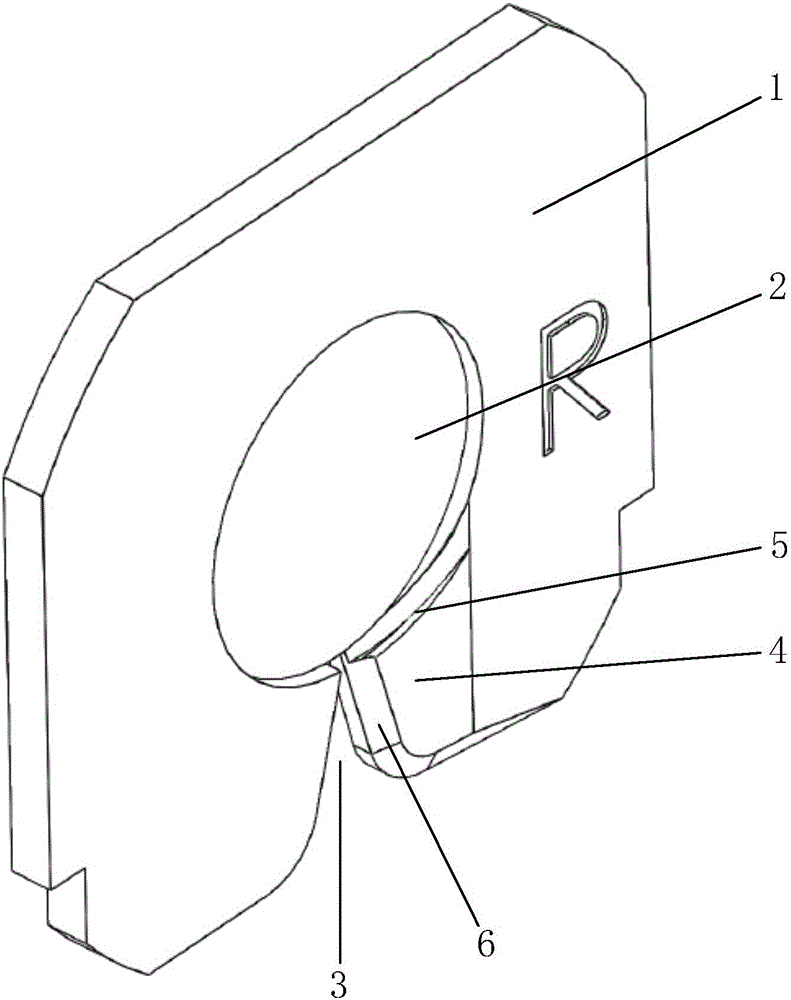

[0023] like Figure 1 to Figure 3 As shown in , the embodiment of the present invention provides a spacer for winding double coils, which includes a spacer body 1, and a winding shaft is provided in the middle of the left and right sides of the spacer body 1 The installation recess 2 is also provided with an entry line snap-in notch 3, the entry line snap-in notch 3 extends from the edge of the spacer body 1 to the bobbin installation recess 2, and gradually becomes smaller. Wherein, the thickness of the main body 1 of the spacer is 2 to 5mm, and the angle of the entry line snapping into the notch 3 is 30° to 60°; the installation recess 2 of the winding shaft and the entry line snapping into the notch 3 are both The septum main body 1 is integrally formed.

[0024] When using the spacer sheet for winding double coils described in the present invention, first place the spacer sheet between the left winding shaft and the right winding shaft of the self-adhesive coil winding ma...

Embodiment 2

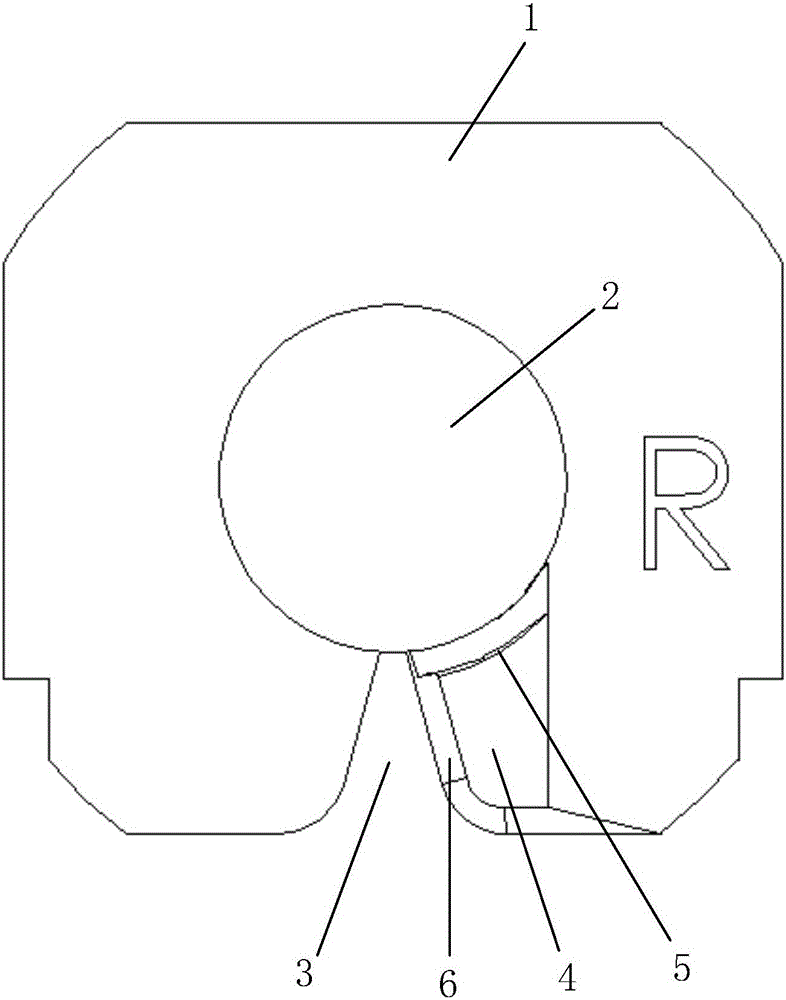

[0028] like Figure 4 As shown in , the embodiment of the present invention provides a spacer for winding double coils, its structure is basically the same as that of Embodiment 1, including a spacer main body 1, and the left and right sides of the spacer main body 1 There is a winding shaft installation recess 2 in the middle of the sides of both sides, and the main body of the spacer 1 is provided with a notch 3 for entering the wire, and the notch 3 for the entry of the line extends from the edge of the main body 1 of the spacer to the winding The bobbin is installed in the concave position 2, and gradually becomes smaller. The only difference is that the main body 1 of the spacer is provided with two notches 3 for entering lines, and the two notches 3 for entering lines are symmetrically arranged on the upper and lower ends of the main body 1 of the spacer, wherein the spacers The mold body 1 is assembled by the left septum 11 and the right septum 12 and is left-right sym...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com