A building power well cooling device assembly with press springs and a filter screen

A technology of cooling device and top pressure spring, which is applied to electrical components and other directions, can solve the problems of complex structure of cooling device, safety risks of building electricity, and difficulty in heat dissipation of cooling device, so as to avoid unstable factors, compact structure, and reduce local overheating. area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

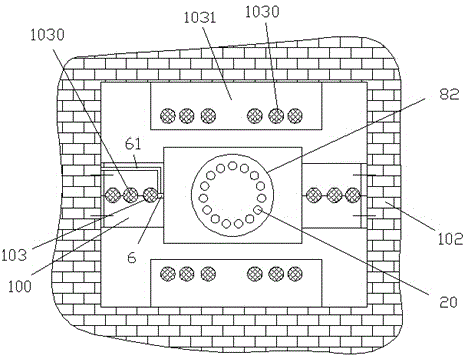

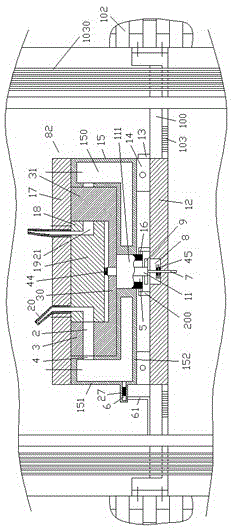

[0011] Combine below Figure 1-2 The present invention will be described in detail.

[0012] According to an embodiment, a cooling device assembly for a power well in a building with a top pressure spring and a filter screen includes a plurality of cooling devices that are separately provided along the vertical direction of the power well and supplied with gas by the gas delivery pipe 61, Each cooling device includes a cooling device body 82 and fixing brackets 100 arranged on both sides of the cooling device body 82 for fixing on two opposite side walls 102 of the power well, and the fixing brackets 100 are provided with The cable fixing hole 103 for the power cable 1030 to pass through, the cooling device body 82 includes an annular cavity housing 15 provided with a gas inlet nozzle 6 to communicate with the gas delivery pipe 61, the gas inlet pipe A filter screen 27 is arranged in the nozzle 6 to filter out larger particles and dust in the gas delivered by the gas delivery...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com