Stator assembly

A component and stator technology, applied in the field of stator components, can solve problems such as high cost, troublesome installation, complex structure, etc., and achieve the effect of simple structure, ensuring insulation and ensuring consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

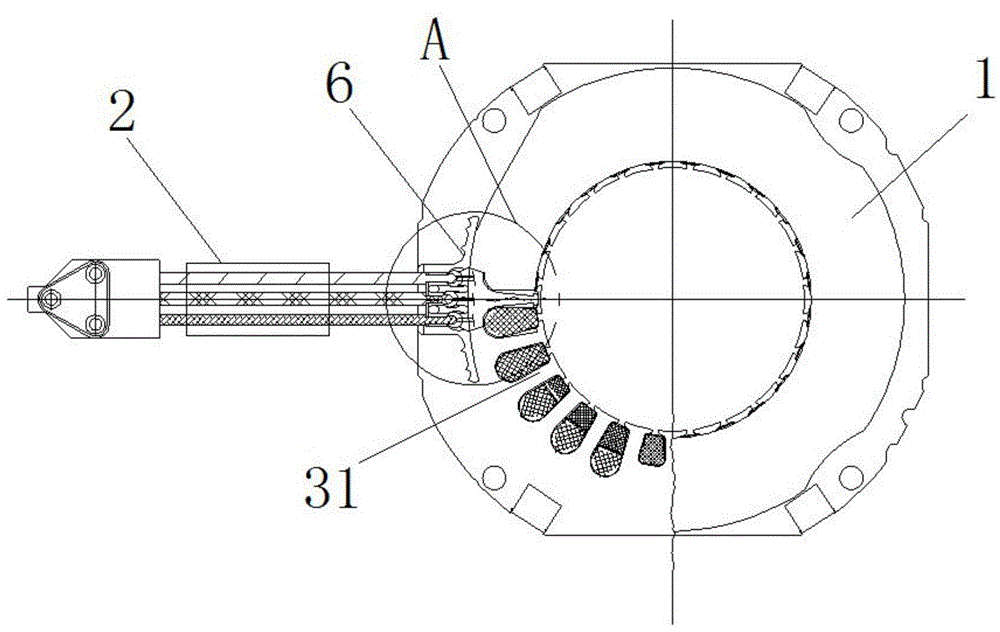

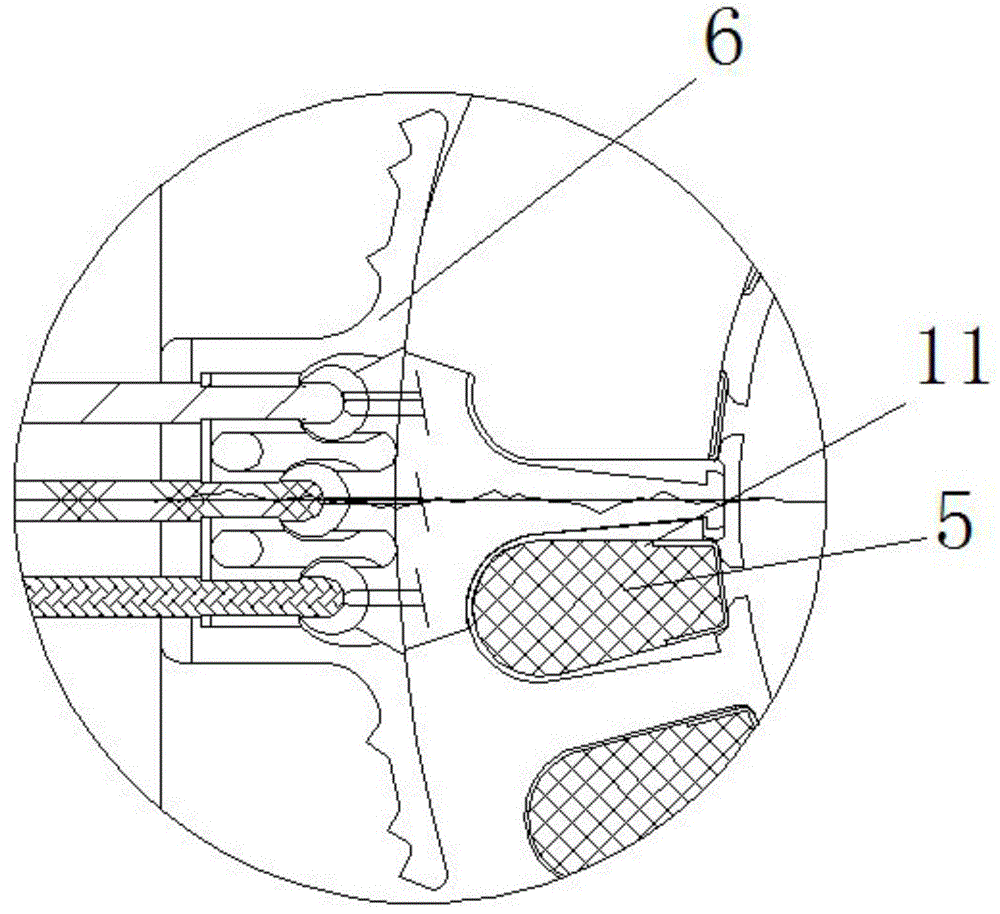

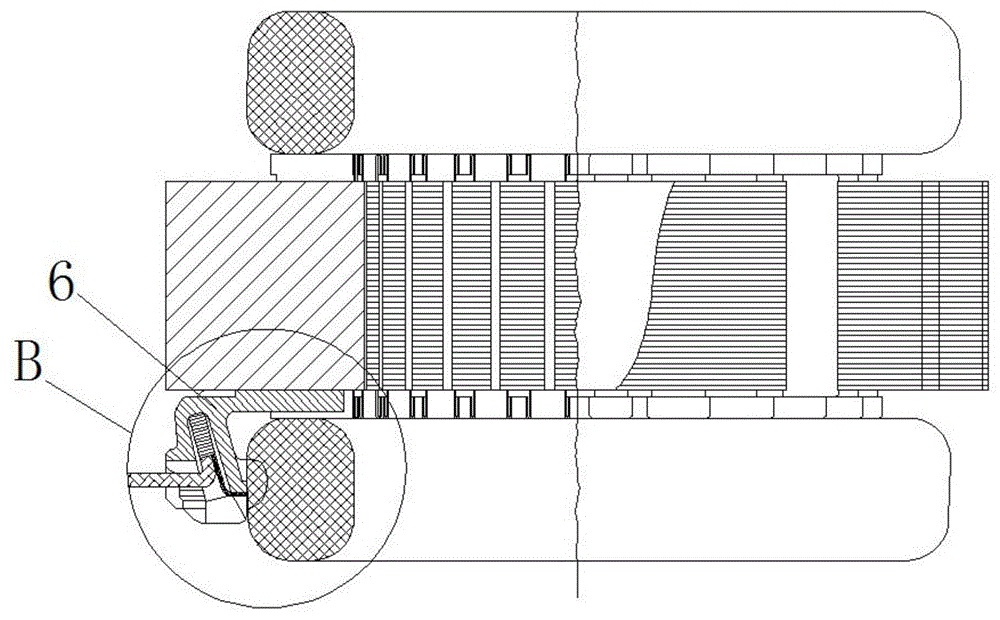

[0036] see Figure 1 to Figure 13 , The stator assembly of this embodiment includes a stator core 1 , a wire harness assembly 2 , a first insulating sleeve 3 , a second insulating sleeve 4 , a winding 5 and a terminal clamp 6 .

[0037] The stator core 1 in this embodiment is provided with several mounting holes 11 that run through the top and bottom, that is, the mounting holes 11 run through the upper and lower end surfaces of the stator core 1, and the mounting holes 11 are arranged at intervals in a ring, such as Figure 13 As shown, both the first insulating sleeve 3 and the second insulating sleeve 4 are installed in the installation hole 11 and form a ring-shaped closed structure along the inner wall of the installation hole 11, and the winding 5 is installed in the above-mentioned closed structure; the wire harness assembly 2 includes wire harness wires 21, The wire terminal 51 is drawn out from the winding 5 , and the harness wire 21 is connected to the wire terminal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com