Replaceable machine-mounted male input power connections

A power connection and power technology, applied in the field of power input connection of electric welding system, can solve problems such as troublesome and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

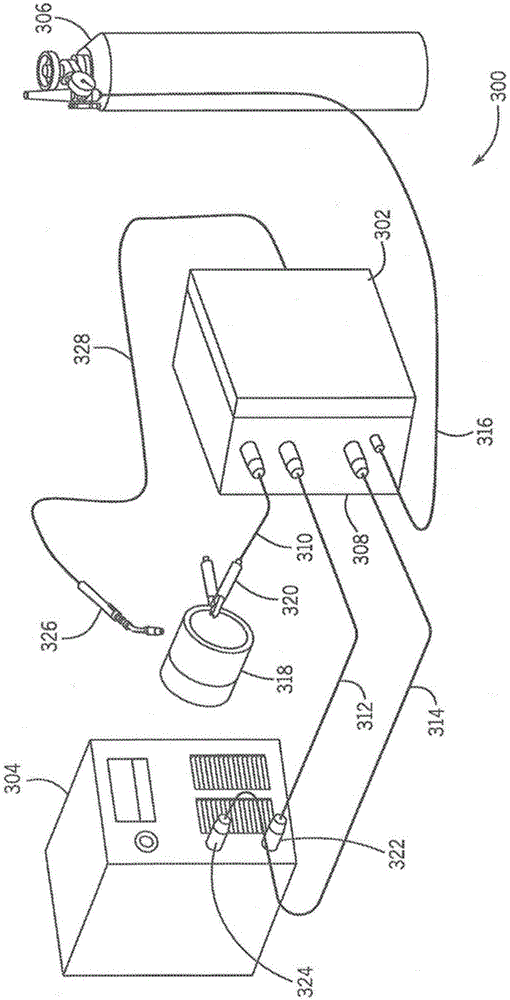

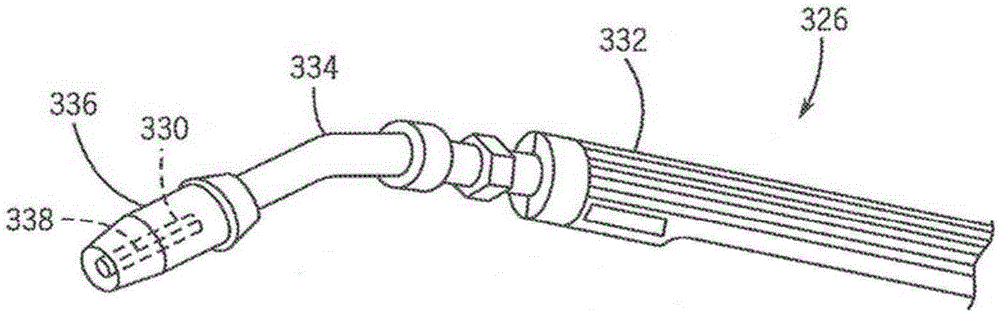

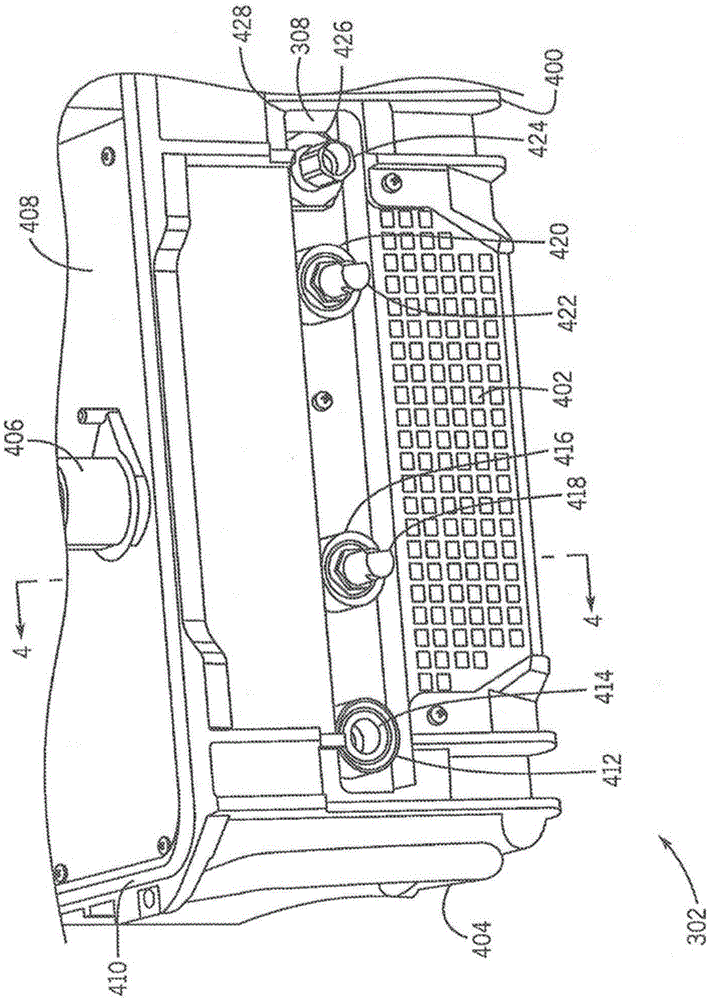

[0024] The present invention includes and is used to directly connect one or more male connections (such as quick connect terminals) to a panel mount (such as integrating the quick connect terminals into a welding wire supply, referred to herein as system and method for a wire feeder). see figure 1 , the general setup of an electric welding system 300 includes a wire feeder 302 connected to a remote power source 304 and a gas source 306 . The illustrated wire feeder 302 is portable and designed to utilize welding current supplied from the remote power source 304, which is capable of supplying electric welding current for welding. The wire feeder 302 includes a power connection side plate 308 having four connectors connected to a working cable 310, a first welding cable 312, a second welding cable 314 and Gas cable 316.

[0025] Specifically, the working cable 310 includes: one end having a male connector received in a female connector on the power connection side panel 308;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com