Production method of gravelly soil

A production method and gravel soil technology, applied in chemical instruments and methods, clay preparation equipment, clay processing equipment, etc., can solve the problems of low fine particle content, high fine particle content, and strength that cannot meet the stress and deformation requirements of high dams, etc. Achieve effective utilization, high production efficiency and high pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

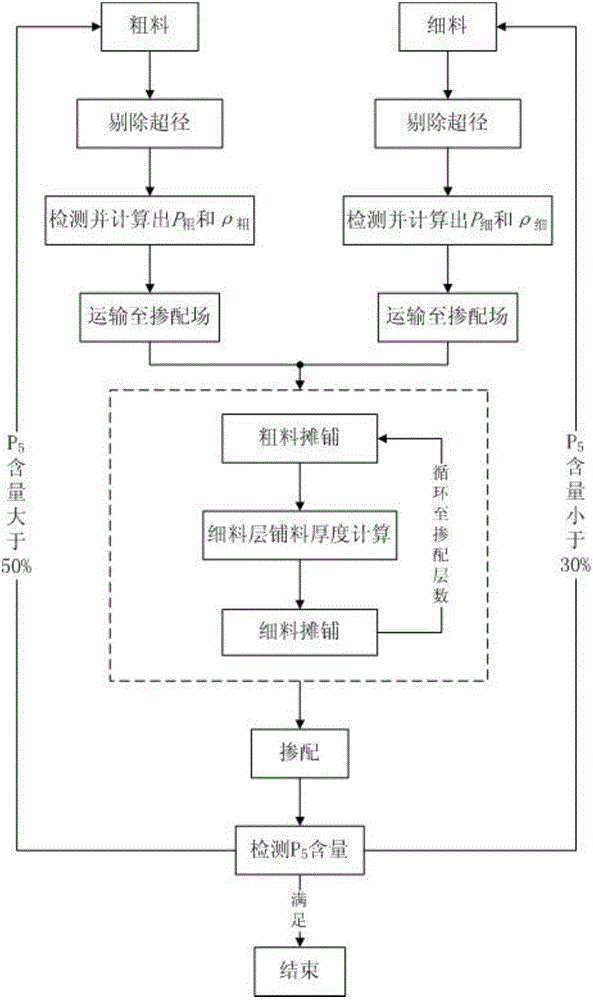

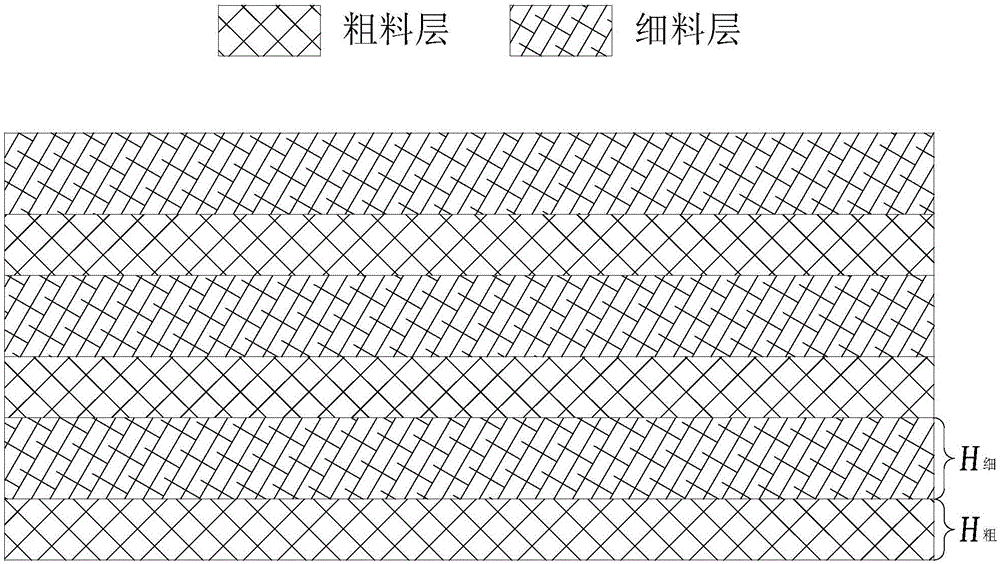

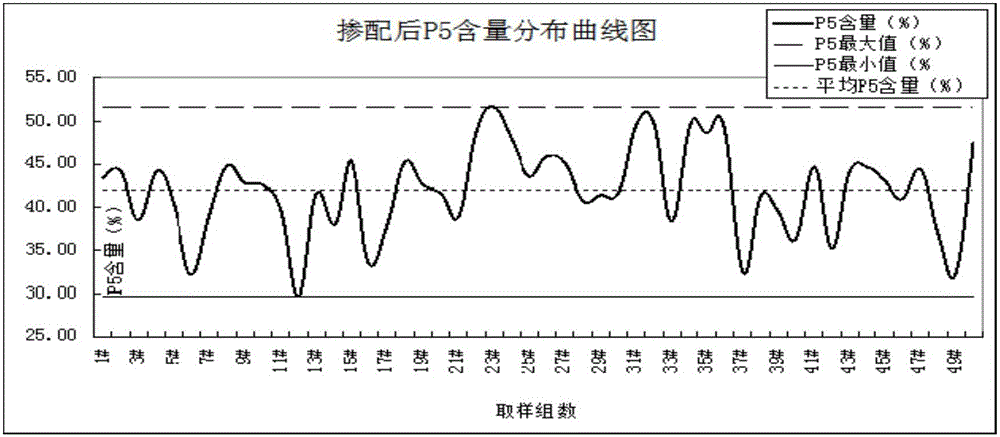

[0045] The soil material in a certain stockyard is mainly glaciation-accumulated gravel-containing soil, and a small amount is slope-diluvial accumulation. Exploration shows that the soil P in the stockyard 5 Coarse material with a content greater than 50% is about 1.1 million m 3 , P 5 The fine material with a content of less than 30% is about 500,000 m 3 , Coarse material and fine material account for 35% of the total reserves.

[0046] a, with P 5 Continuously graded natural soil materials with a content of 50% to 65% are used as coarse materials, and P 5 Continuously graded natural soil materials with a content of less than 35% are used as fine materials; the soil materials in the stockyard are mined in layers from top to bottom according to the coarse material area and the fine material area. layer excavation;

[0047]b. Sieve the mined coarse and fine materials through a simple bar sieve or a vibrating bar sieve, and remove super-diameter boulders with a particle s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com