Swing arm feeding device

A feeding device, swing arm type technology, applied in the field of swing arm type feeding device, can solve the problems of manual installation of raw materials, high production cost, complex structure, etc., to save the loading machine, simplify the structure, save Institutional Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

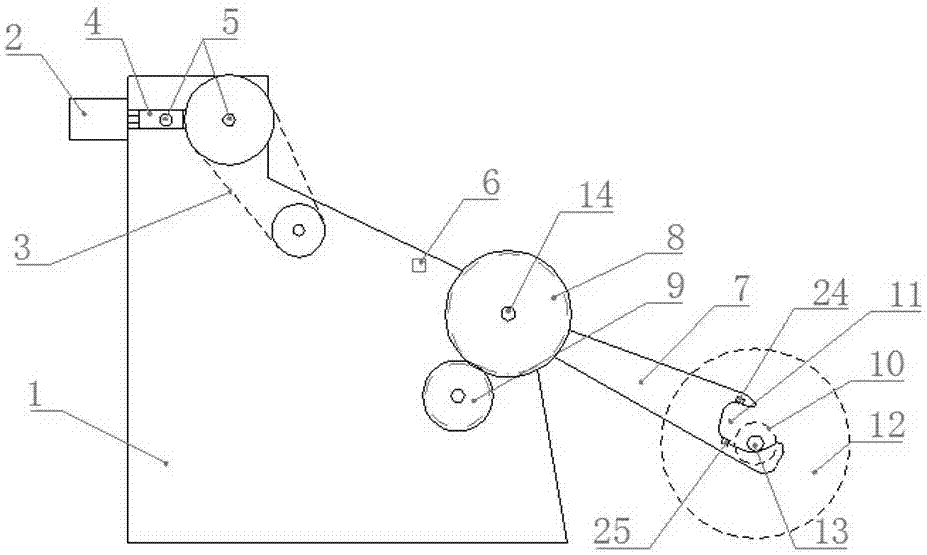

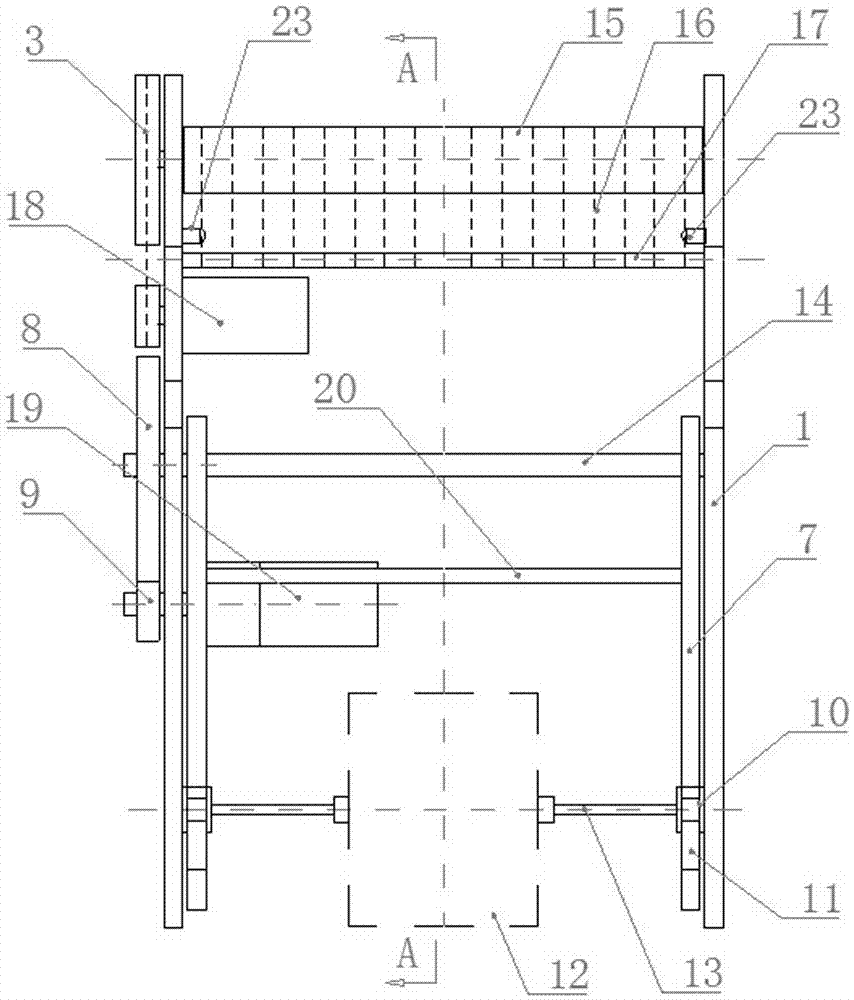

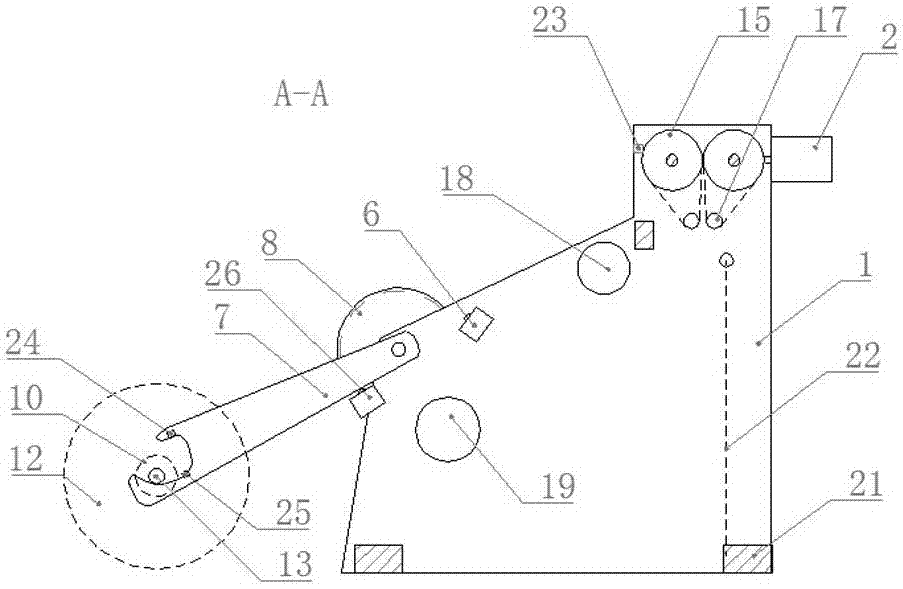

[0020] like Figure 1-Figure 9 As shown, a feeding device for a swing arm type bag making machine in the present invention includes a bracket 1 on which a pair of rubber rollers 15 are mounted, and the rubber roller shaft 5 of one of the rubber rollers 15 is connected to the The rubber roller driving motor 18 on the support 1 is connected by transmission, and it is characterized in that the rear end of the support 1 is hinged with one end of a pair of swing arms 7 through a drive shaft 14, and the other end of the swing arm 7 is provided with an opening Upward groove 11; the drive shaft 14 is rotationally connected to the bracket 1 and is fixedly connected to the swing arm 7, and one end of the drive shaft 14 is connected to the swing arm drive motor 19 mounted on the bracket 1 through a gear transmission mechanism; A roller 10 is respectively housed at both ends of the raw material shaft 13 .

[0021] The width of the bottom of the groove 11 on the swing arm 7 leaves space f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com