A supporting loading device for loading and unloading building materials

A loading device and building material technology, applied in the direction of loading/unloading, transportation and packaging, rollers, etc., can solve the problems of falling, easy shaking, lack of fixing mechanism for goods, etc., and achieve the effect of reducing shaking and reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

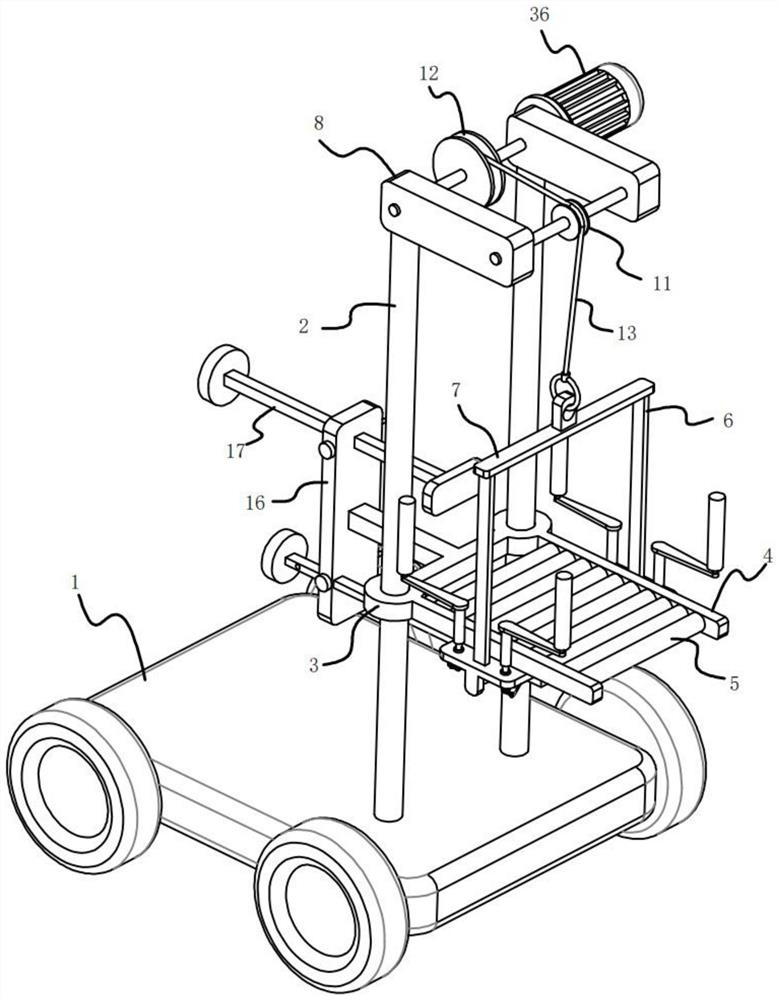

[0022] refer to Figure 1-7 , a support loading device for loading and unloading building materials, including a walking platform 1, the walking platform 1 can be a flatbed truck driven by electricity. The upper surface of the walking platform 1 is fixedly equipped with two corresponding vertical bars 2, and each vertical bar 2 is equipped with a movable sleeve 3, and a horizontal bar 4 is fixedly connected to the two movable sleeves 3, and two The crossbars 4 are arranged parallel to each other, and several roller bodies 5 are installed between the two crossbars 4 at equal intervals along the length direction. Connecting rod 15, vertical plate 16 is fixedly installed on the outer end of connecting rod 15, and a driving mechanism is installed on the upper part of vertical plate 16, and a driving mechanism is fixedly installed on the bottom of vertical plate 16, and a driving mechanism is fixedly installed on the lower surface of two cross bars 4. The cargo fixing mechanism co...

Embodiment 2

[0026] refer to Figure 1-7 , as another preferred embodiment of the present invention, the difference from Embodiment 1 is that the driving mechanism includes a second insertion rod 19, an insertion hole 20, and a second insertion rod 19 and a rack 21 are provided through the lower part of the riser 16. A rack 21 is fixedly connected to the inner end of the second insertion rod 19 , and a plurality of insertion holes 20 are opened on the second insertion rod 19 .

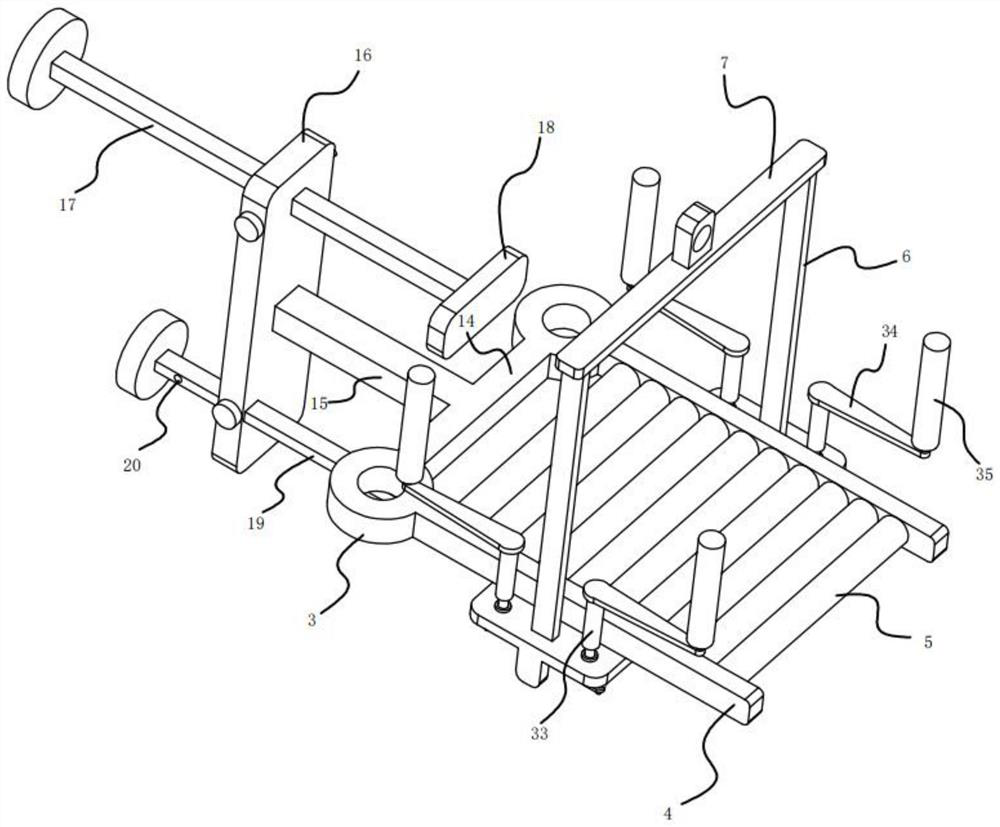

[0027] The cargo fixing mechanism includes a fixed plate 22, a horizontal plate 23, a rotating shaft 24, a gear 25, a rectangular block 26, a curved bar 27, a movable block 28, a connecting rod 29, a connecting plate 30, a vertical plate 31, a guide rod 32, a movable rod 33, Plate 34, cylinder 35, a fixed plate 22 is fixedly installed on the lower surfaces of the two cross bars 4, a horizontal plate 23 is fixedly installed between the two fixed plates 22, and a rotating shaft is rotatably installed in the middle of...

Embodiment 3

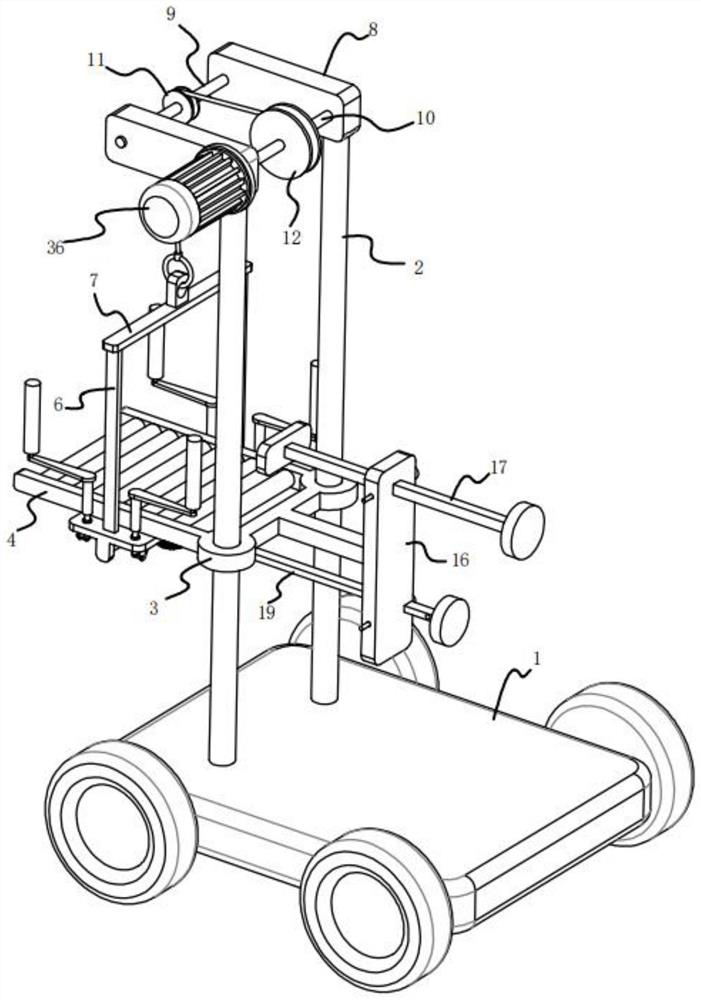

[0030] refer to Figure 1-2 , as another preferred embodiment of the present invention, the difference from Embodiment 1 is that the winding mechanism includes a side plate 8, a first fixed shaft 9, a second fixed shaft 10, a guide wheel 11, a winding wheel 12, and a cable 13 , a side plate 8 is fixedly installed on the top ends of the two vertical bars 2, and a first fixed shaft 9 and a second fixed shaft 10 arranged in parallel are fixedly installed between the two side plates 8, and the first fixed shaft 9 and the top plate 7 Correspondingly arranged, on the first fixed shaft 9, a guide wheel 11 is rotatably installed, and on the second fixed shaft 10, a winding wheel 12 is rotatably installed, and one end of the cable 13 is fixedly wound on the winding wheel 12, and the other end of the cable 13 is After passing through the guide wheel 11, it is fixedly connected on the top plate 7.

[0031] By controlling the winding motor 35 to wind up the cable 13, the height of the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com