Water transfer printing workpiece drying device

A drying device and water transfer technology, applied in the general parts of printing machinery, printing, printing machines, etc., can solve the problems of heat loss, easily scalded operators, low efficiency, etc., to reduce heat loss and avoid potential safety hazards , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

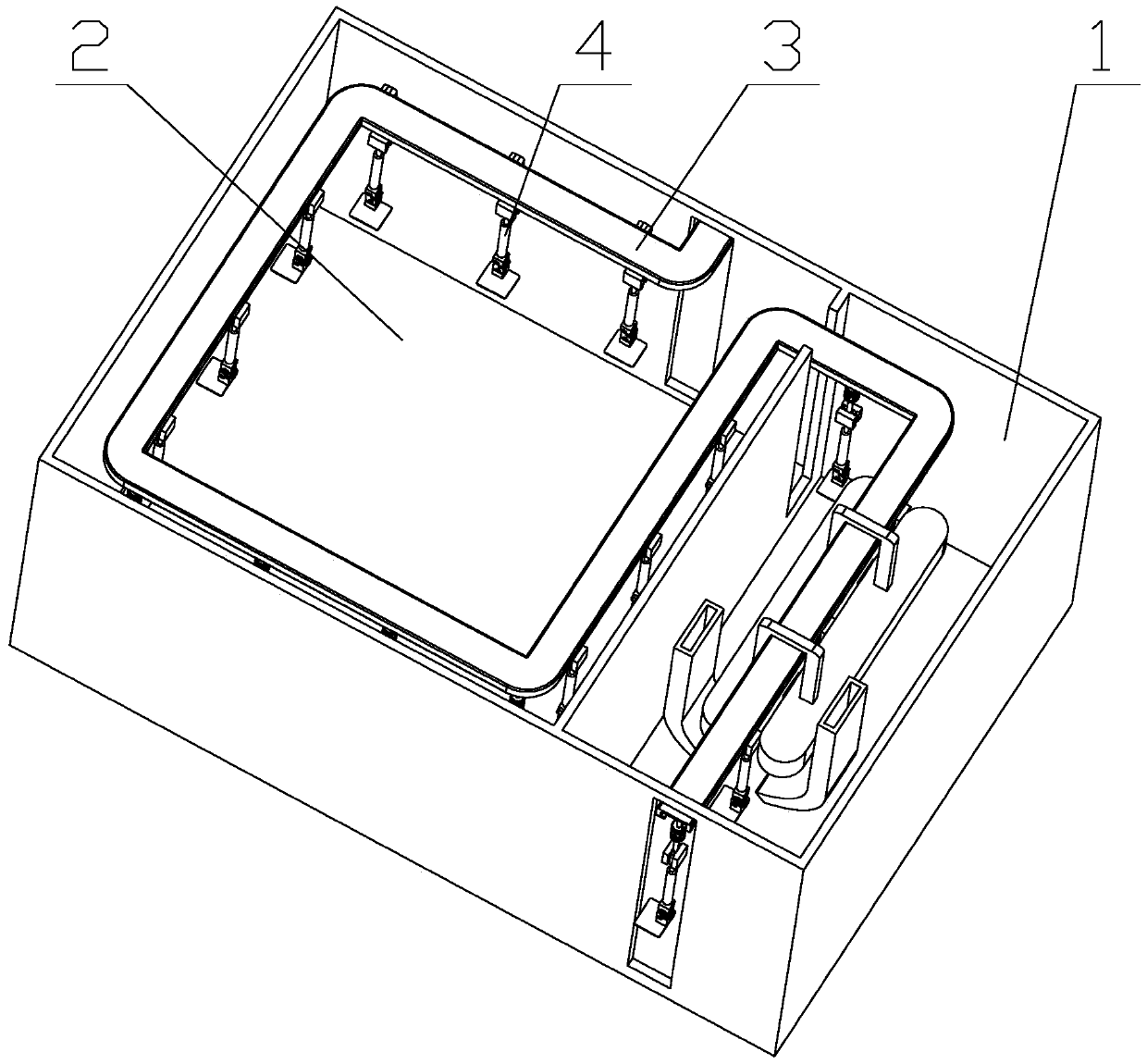

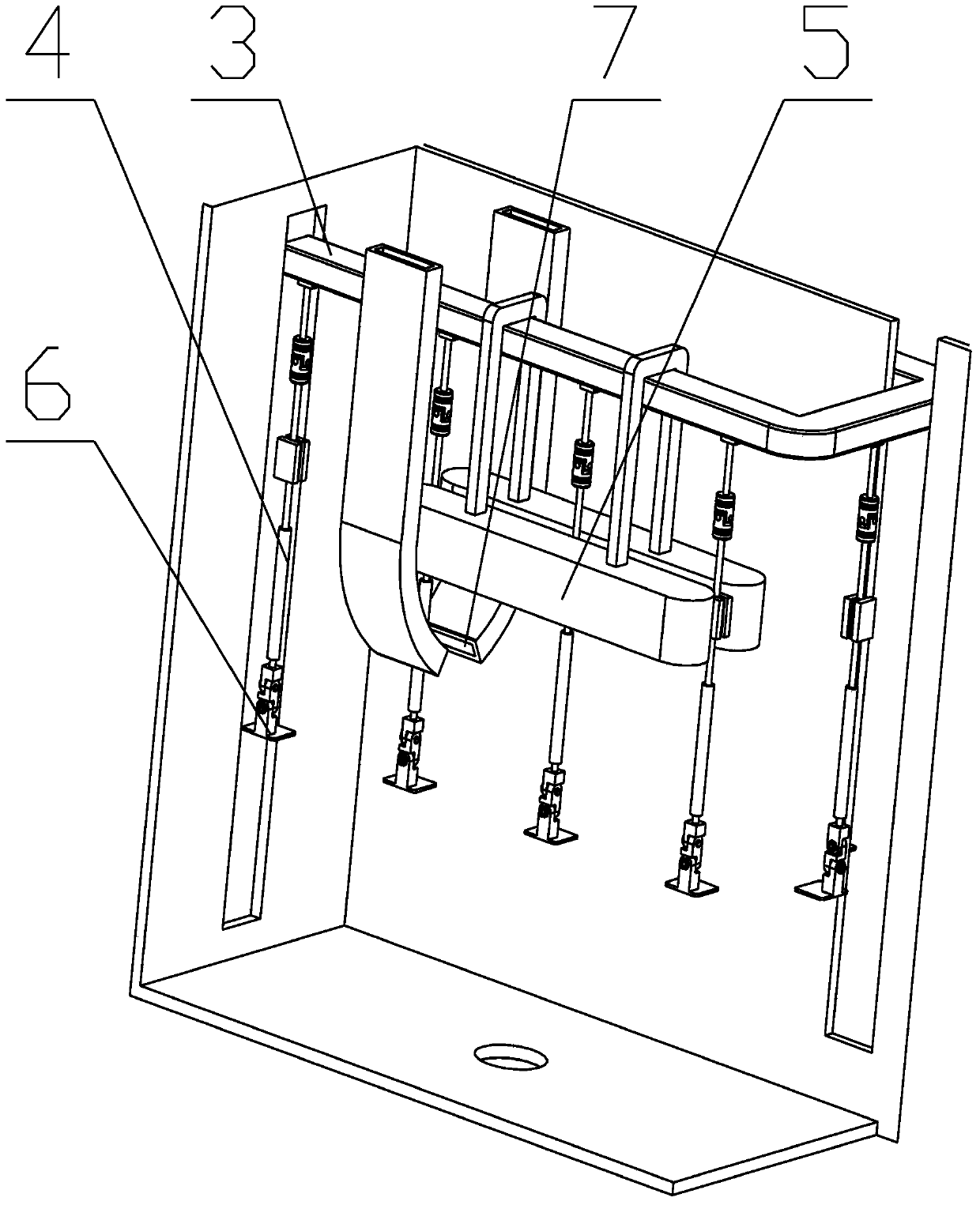

[0021] As shown in the figure, the water transfer printing workpiece 6 drying device of the present invention includes an air drying chamber 1 for drying the water stain on the surface of the workpiece 6 and a baking chamber 2 for drying the workpiece 6, the air drying chamber 1 and The top of the baking chamber 2 is provided with a guide rail 3 for automatically transporting the workpiece 6. The track of the guide rail 3 passes through the drying chamber 1 to the baking chamber 2, and the two ends of the track of the guide rail 3 extend to the outside of the drying chamber 1 and the baking chamber 2 respectively. , the guide rail 3 is evenly provided with connecting pieces 4 for hoisting the workpiece 6 .

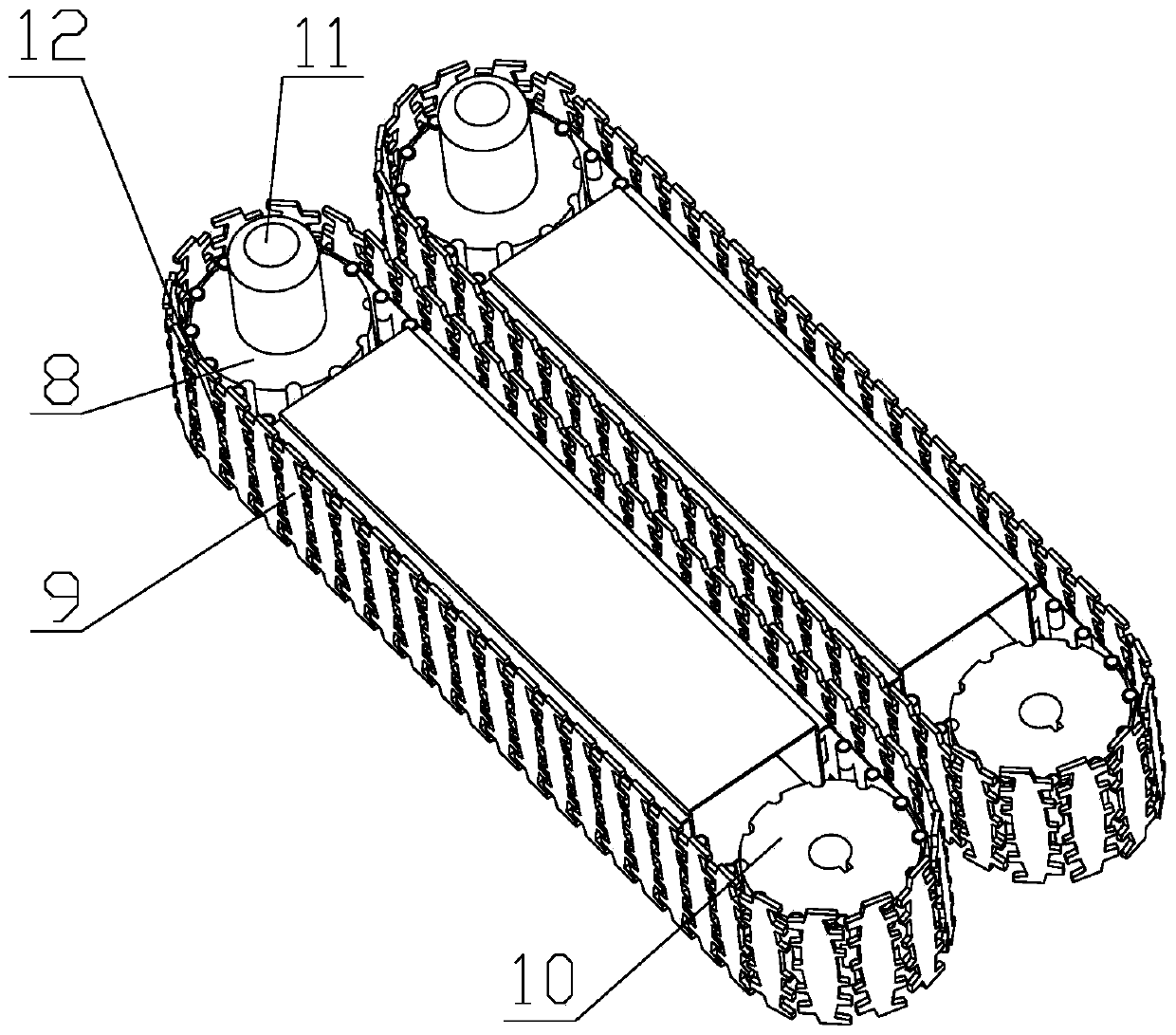

[0022] In the specific implementation process, the automatic delivery function of the guide rail 3 can be realized by means of a chain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com