Crane horizontal wheel mechanism capable of adjusting clearance

A technology for adjusting gaps and horizontal wheels, applied in the field of machinery, can solve problems such as increased gap between the horizontal wheel and the track, deformation and damage of the horizontal wheel shaft, and lack of buffering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

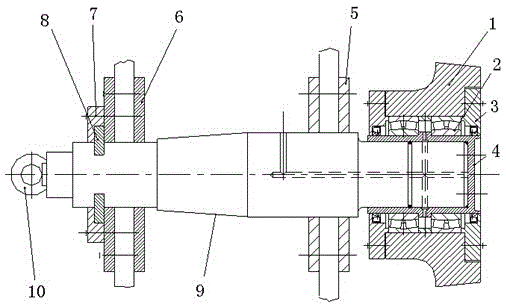

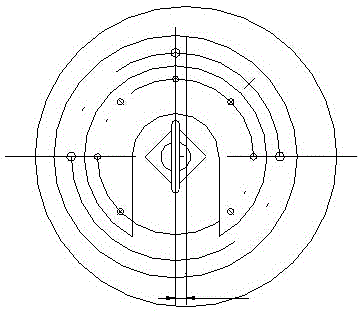

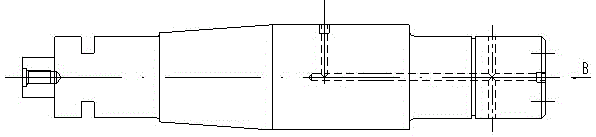

[0016] Such as figure 1 with figure 2 As shown, the crane horizontal wheel mechanism with adjustable clearance includes a horizontal wheel body 1, a bearing 2, a bearing end cover 3, a bushing 4, a half-moon pin 8 and an eccentric shaft 9, one end of the horizontal wheel body 1 is connected to the eccentric shaft 9, and two There is a bearing 2 between them, and a shaft sleeve 4 is arranged between the bearing 2 and the horizontal wheel body 1; both ends of the bearing 2 are provided with bearing end covers 3, and there is a hole in the middle of the two bearing end covers 3, and the two bearing end covers 3 are connected with the horizontal wheel body 1. The wheel body 1 is fixedly connected, and the inner circular surfaces of the two bearing end covers 3 are squeezed and connected with the bearing gland. Wherein, the bearing 2 is a paired bearing.

[0017] The middle position and the other end of the eccentric shaft 9 are supported at two points by two positioning plates,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com