Efficient and rotational-flow-free funnel

A technology without swirling flow and funnel, which is applied in the direction of funnel, bottle filling, packaging, etc., which can solve the problems of affecting the liquid throughput of the funnel, affecting production or life, and increasing the occupied area, so as to avoid bringing in air and blocking liquid Channel, large liquid flow, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

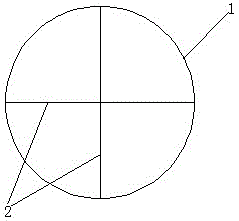

[0032] A high-efficiency non-swirl funnel, such as figure 1 As shown, a funnel body 1 is included, and a baffle assembly is provided inside the funnel body 1, and the baffle assembly separates the inside of the funnel body 1 into a plurality of fluid passages;

[0033] The above-mentioned baffle assembly includes multiple full baffles 2 , and one ends of the multiple full baffles 2 are connected at one point, and the other ends of the multiple full baffles 2 are vertically connected to the inner wall of the funnel body 1 .

[0034] In this embodiment, the above-mentioned funnel body 1 is columnar or wedge-shaped, the columnar shape is specifically cylindrical, and the wedge-shaped is specifically conical.

[0035] The funnel body 1 is provided with a plurality of axial strip-shaped holes, and the plurality of axial strip-shaped holes are evenly distributed along the radial direction of the funnel body 1 .

[0036] The inner lower part of the above-mentioned funnel body 1 is p...

Embodiment 2

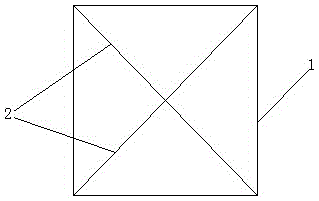

[0039] This embodiment is basically the same as Embodiment 1, the difference between the two is:

[0040] Such as figure 2 As shown, the above-mentioned funnel body 1 is in the shape of a column or a wedge, the column is specifically a cuboid, and any surface of the wedge is trapezoidal.

Embodiment 3

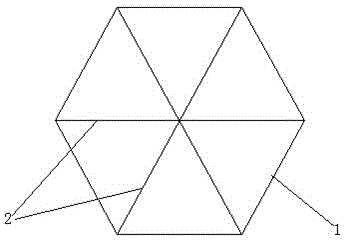

[0042] This embodiment is basically the same as Embodiment 1, the difference between the two is:

[0043] Such as image 3 As shown, the above-mentioned funnel body 1 is columnar or wedge-shaped, the cross-section of the column is polygonal, and the cross-section of the wedge is also polygonal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com