A method for manufacturing conductive polymer pyroelectric nano film

A technology of conductive polymers and nano-films, applied in coatings and other directions, can solve problems such as poor stability, difficulty in obtaining high-performance thermoelectric materials, and low energy factors, and achieve good high-temperature thermal stability, good application prospects, and high heat The effect of discharge coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

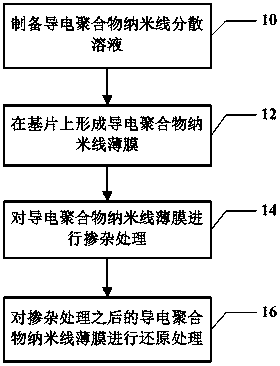

Method used

Image

Examples

example 1

[0061] ① Dissolve polysuccinic acid bis-(2-ethylhexyl) sodium sulfonate in N, N dimethylformamide solvent, the concentration of polysuccinic acid bis-(2-ethylhexyl) sodium sulfonate is 2.5 moles / L to form a nanowire stencil solution for monomer polymerization;

[0062] ② Dissolving 3,4-ethylenedioxythiophene in n-butanol solvent, the concentration of 3,4-ethylenedioxythiophene is 1 mole / liter, forming a monomer solution;

[0063] ③After mixing the solutions formed by ① and ②, add an aqueous solution of iron toluenesulfonate to initiate polymerization, and the concentration of toluenesulfonic acid is 2 mol / liter, thereby obtaining ultra-long nanowires of poly-3,4-ethylenedioxythiophene solution;

[0064] ④ Mix poly-3,4-ethylenedioxythiophene nanowire solution with chloroform solvent (volume ratio 4:1) to obtain conductive polymer nanowire solution suitable for LB film spreading;

[0065] ⑤ Use a micro-injector to extract 800 μl of the conductive polymer nanowire solution obt...

example 2

[0070] In Example 2, the conductive polymer monomer is thiophene, and the rest of the materials and manufacturing process are similar to those in Embodiment 1, so as to obtain a polythiophene nanowire pyroelectric film.

example 3

[0072] In Example 3, the conductive polymer monomer is α-chloromethylthiophene, and the rest of the materials and manufacturing process are similar to those in Embodiment 1, so as to obtain poly-α-chloromethylthiophene nanowire pyroelectric film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com