Adhesion promoter for rubber and its preparation method and application

An adhesion promoter and rubber technology, applied in the preparation of organic compounds, chemical instruments and methods, organic chemistry, etc., can solve the problems of high cost, difficult production technology, difficult to sublime, etc., to reduce the dosage and reduce the amount of raw materials. , The effect of not easy to sublime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

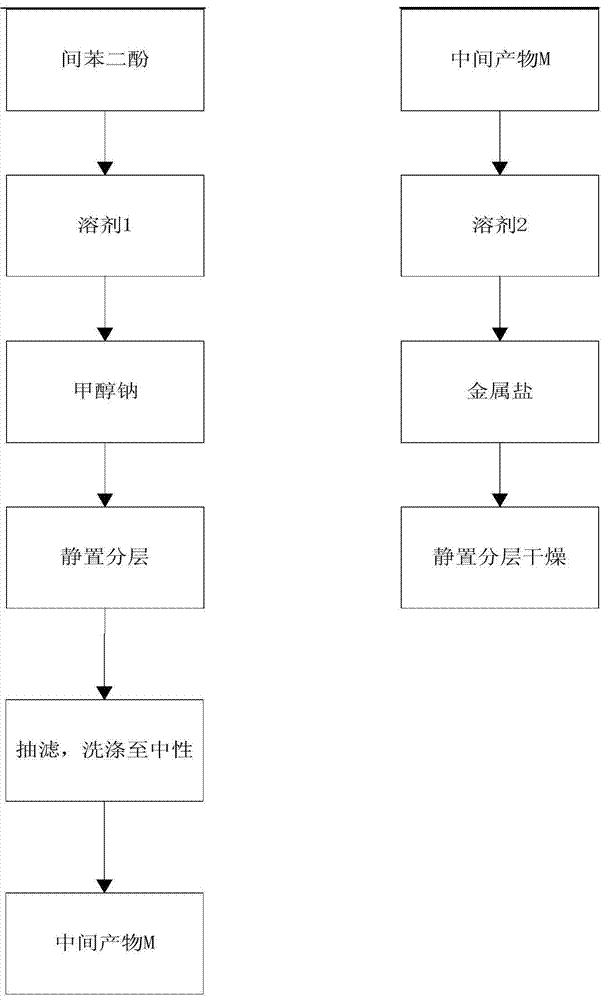

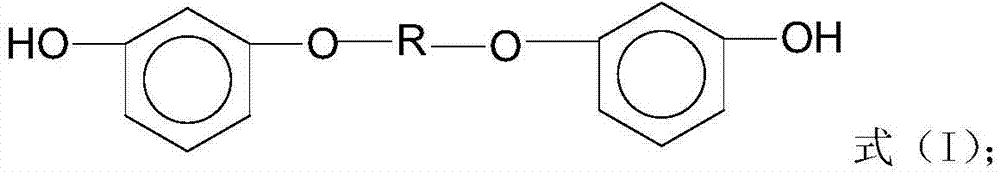

Embodiment 1

[0034] Add 110 grams of resorcinol and 300 grams of anhydrous methanol into a 500 mL four-neck flask protected by nitrogen gas, heat up to 70 degrees to completely dissolve and start stirring, and slowly add 27 grams of sodium methoxide. Reflux for 10 minutes after the addition, stand to separate the layers, filter off the solvent and wash to pH=6.5-7. Add 200 grams of anhydrous tetrahydrofuran and raise the temperature to 100 degrees, then slowly add 140 grams of crushed anhydrous cobalt sulfate, keep stirring for 30 minutes after the addition, and remove the solvent at normal pressure to 120 degrees to start vacuum distillation. The residue was vacuum-dried and cooled to room temperature under the protection of nitrogen to obtain 151.9 g of dark reddish-brown powder. After identification, the product is a reddish-brown powder, and there are characteristic absorption peaks of benzene ring (1500cm-1, 1600cm-1) and phenolic hydroxyl characteristic absorption peaks (3200cm-1) th...

Embodiment 2

[0037] Add 55 grams of resorcinol and 100 grams of anhydrous tetrahydrofuran into a 500 mL four-neck flask protected by nitrogen, heat up and start stirring, slowly add 25 grams of potassium acetate, continue the reaction for 30 minutes, and let it stand to adjust the pH=6.5-7. The intermediate product was continuously reacted with 62.5 grams of nickel acetate, and after a large amount of salt was precipitated, it was suction filtered and washed three times with anhydrous methanol. Vacuum dried for 0.5 hour, and cooled to room temperature under nitrogen protection to obtain about 75 g of the product. After identification, the product is gray powder, and there are characteristic absorption peaks of benzene ring (1500cm-1, 1600cm-1) and phenolic hydroxyl characteristic absorption peaks (3200cm-1) through infrared test. After elemental analysis, C: 51.9%, H: 3.5%, Co: 21.1%, namely the chemical structure of the product:

[0038]

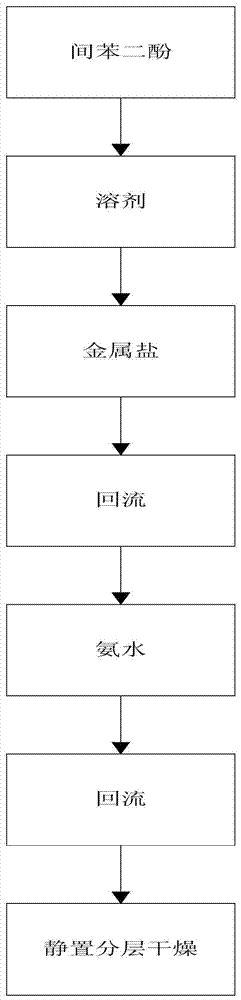

Embodiment 3

[0040] Add 55 grams of resorcinol and 100 mL of absolute ethanol into a 500 mL four-neck flask protected by nitrogen. Start stirring and heat up to 70 degrees for complete dissolution, slowly add 60 grams of crushed cobalt acetate. Hold for 0.5 hours after addition. Add 300 mL of concentrated ammonia water, keep at 80°C for 5 hours, filter the precipitate and wash it with ethanol until neutral, and gradually cool to room temperature under the protection of nitrogen to obtain 73 g of the product. After identification, the product is a reddish-brown powder, and there are characteristic absorption peaks of benzene ring (1500cm-1, 1600cm-1) and phenolic hydroxyl characteristic absorption peaks (3200cm-1) through infrared testing. After elemental analysis, C: 51.0%, H: 3.3%, Co: 21.0%, namely the chemical structure of the product:

[0041]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com